铝材材料技术(AMT), a developer and supplier of aluminum alloy powders for additive manufacturing, has partnered with theUniversity of Birminghamto enhance understanding of the metallurgy of 3D printedA20X铝合金。

The two parties are investigating the characteristic properties of the alloy when produced via laser powder bed fusion (LPBF) and direct energy deposition (DED) 3D printing techniques. They will also observe the effects on compositional changes, heat treatments, and additive manufacturing process parameters of 3D printed components from A20X.

“A20X has been successfully adopted into fully qualified production of aerospace components via additive manufacture,” said Martin McMahon, Business Development Director for AMT. “The reliability of the A205 alloy has been proven to be more than adequate in high strength, high ductility and high operating temperature applications, so we are now building on our extensive development programs, to create an even greater understanding of the fundamental metallurgy of the AM alloy.”

3D打印铝

Aluminum alloys are commonly used for manufacturing automotive and aerospace components, and 3D printing companies are continually seeking to develop metals with enhanced mechanical performance, in order to expand on these applications and create parts with improved qualities.

仅在过去的一年中,总部位于汉堡的铝制专家Fehrmann ALLOYS推出了其最新的高性能铝合金,用于3D打印Almgty 90,而金属AM专家Amaero的铝合金Amaero热(高工作温度)AL进入了最后阶段国际专利批准in June.

Meanwhile, California’sHRL实验室功能化the strongest additive manufacturing aluminumto date with the launch ofAluminum 7A77.60L粉,那是made commercially available2019年10月。NASA的Marshall Space Flight Centerhas since begun applying the material to the production oflarge-scale aerospace components, while HRL has built an application presenting 7A77’s potential in heat transfer and flow applications alongside 3D design and engineering software companynTopologyand aerospace manufacturing service providerMorf3D.

Elsewhere,high performance materials manufacturerQuestek Innovations LLC宣布开发新的铝合金3D打印机原料in collaboration with the德国航空航天中心(DLR), and German metal 3D printer manufacturerSLM Solutions与之搭配Honeywell’s aerospace division to产生参数集for 3D printing aluminum F357, with the ultimate aim to 3D print aircraft components that meet industry standards.

A20X家族

A20X is a family of high-strength aluminum-copper alloys developed and patented by AMT, and is deployed within the aerospace and high-end motorsports sectors. The A20X family is made up of A205, a casting alloy with Metallic Materials Properties Development and Standardization (MMPDS) approval, A205/F1, an FIA approved casting alloy, and A207, a silver-free casting alloy. Also included are two powders designed for LPBF 3D printing applications, 2A05 (A205) and 2B05 (A205/F1).

A20X粉末具有通过独特的固化机制实现的高度精制的微观结构,该机制提供了几乎完全各向同性的特性,其中材料在各个方向上具有相同的属性值。根据AMT,与其他合金相比,这些特性提供了更大的强度,疲劳和热特性。

先进的材料和加工(AMPLab)the University of Birmingham have carried out several successful projects to build sample parts from A20X in the past.

“The university’s experience with this alloy dates back to the early days of its introduction as a metal powder for additive manufacturing, and we have carried out many successful projects characterizing the physical properties of candidate parts,” said Moataz Attallah, Professor of Advanced Materials Processing and Director of AMPLab at the School of Metallurgy & Materials at the university.

“因此,现在我们正在与AMT紧密合作,以更深入地研究使这种合金如此独特的原因,并且通过选择AM工具和各种各样的材料表征技术,我们可以很好地实现这一目标。”

订阅3D打印行业newsletter有关增材制造中的最新消息。雷电竞充值您也可以通过关注我们来保持联系Twitter和喜欢我们足总cebook.

请务必在所选播客播放器上订阅另一个维度播客,以确保您永远不会错过一集。

寻找添加剂制造业的职业?雷电竞充值访问3D Printing Jobsfor a selection of roles in the industry.

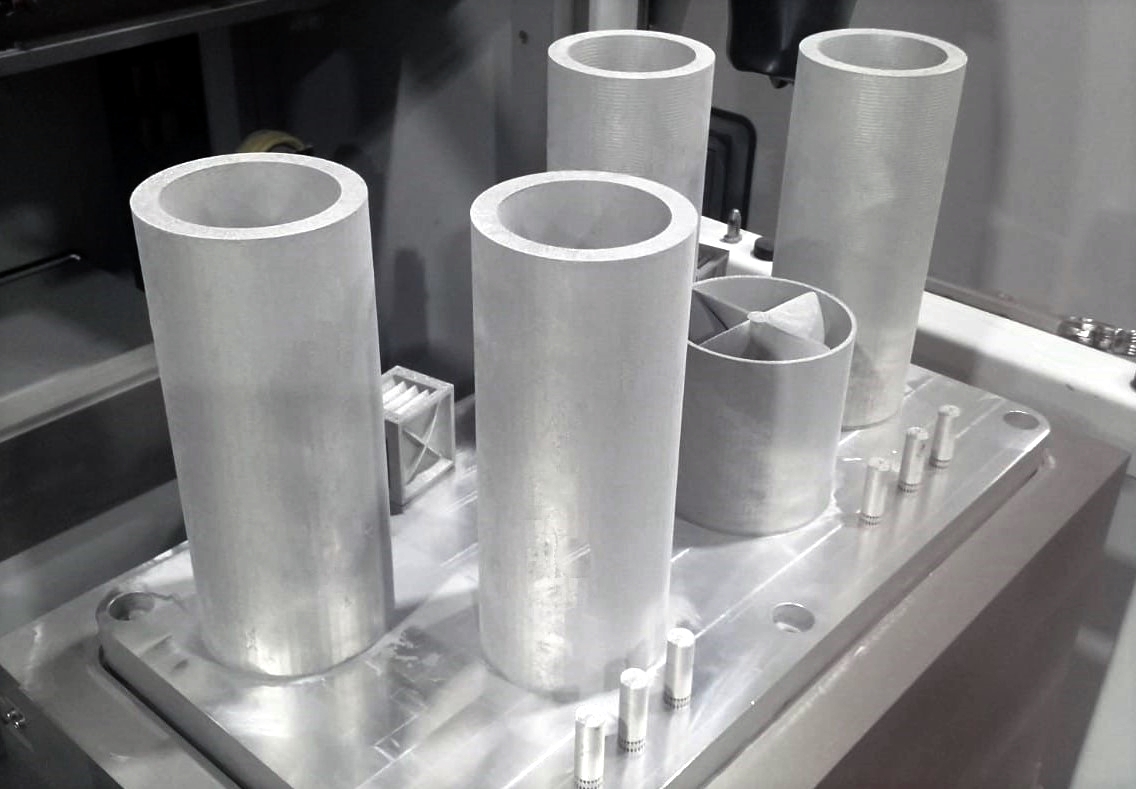

Featured image shows large cylinder samples printed with A20X. Image via Aluminium Materials Technologies.