总部位于英国的后处理专家雷电竞充值增材制造技术(AMT)已收到Innovate UKgrant worth £87,000 to develop a new organic solvent designed specifically for the post-processing of elastomer materials.

专门为热塑性弹性体such as TPU, the solvent can be used in AMT’s PostPro Chemical Vapor Smoothing Process. The company will use the grant to further fast track its research and development program to produce a new generation of bio-renewable chemistries, with the goal to improve sustainability within the 3D printing post-processing market.

“开发可持续的解决方案,进一步促进添加剂制造业的工业化是我们在AMT的主要重点,我们已经证明了我们的后化学蒸气平滑技术,” AMT R&D全球负雷电竞充值责人Konstantin Rybalcenko博士说。“通过利用创新的英国可持续性资金来开发为弹性体开发这种新的消费,我们正在以更加可持续的方式为客户提供技术的能力。”

A new-generation organic solvent

AMT was awarded £87,000 as part of Innovate UK’sSustainable Innovation competition它的创建是为了帮助英国的所有部门恢复,成长和创造新的机会,因为它们从全球199大流行中脱颖而出。

AMT has leveraged the grant to produce a new organic solvent designed specifically for the post-processing of thermoplastic elastomers such as TPU, TPE, TPA, and others.

The new solvent is bio-renewable and can be used in AMT’s PostPro Chemical Vapor Smoothing process alongside the company’s current organic consumable offering. At present, AMT is using the solvent for prototyping applications, and the final product will be globally available in Q2 2021.

“We look forward to working with OEM industrial partners to implement this next-generation consumable into 3D printing factories across the globe,” added Rybalcenko.

AMT最近一直很忙,closed a £2.5 million funding roundin March that brought the total amount raised by the company to more than £7 million. The proceeds will be used to accelerate the company’s growth and product development plans for the industrial 3D printing sector.

该公告是在AMT最近与跨国印刷公司达成的合作伙伴关系之后的。HP提供端到端其多喷气融合的后处理服务(MJF) technologies to its industrial customers. Only last week, the company announced it had teamed up with Japanese electronics manufacturer三菱电to speed up automated additive manufacturing post-processing with the development of afully-automated post-processing machinefor 3D printed parts that incorporates articulated robotic arms.

PostPro Chemical Vapor Smoothing technology

AMT的Postpro Technologry于2018年推出,是专利的,全自动的化学蒸气平滑工艺,用于3D印刷零件。该技术试图通过更换手动后处理步骤为制造商提供明显的成本节省。

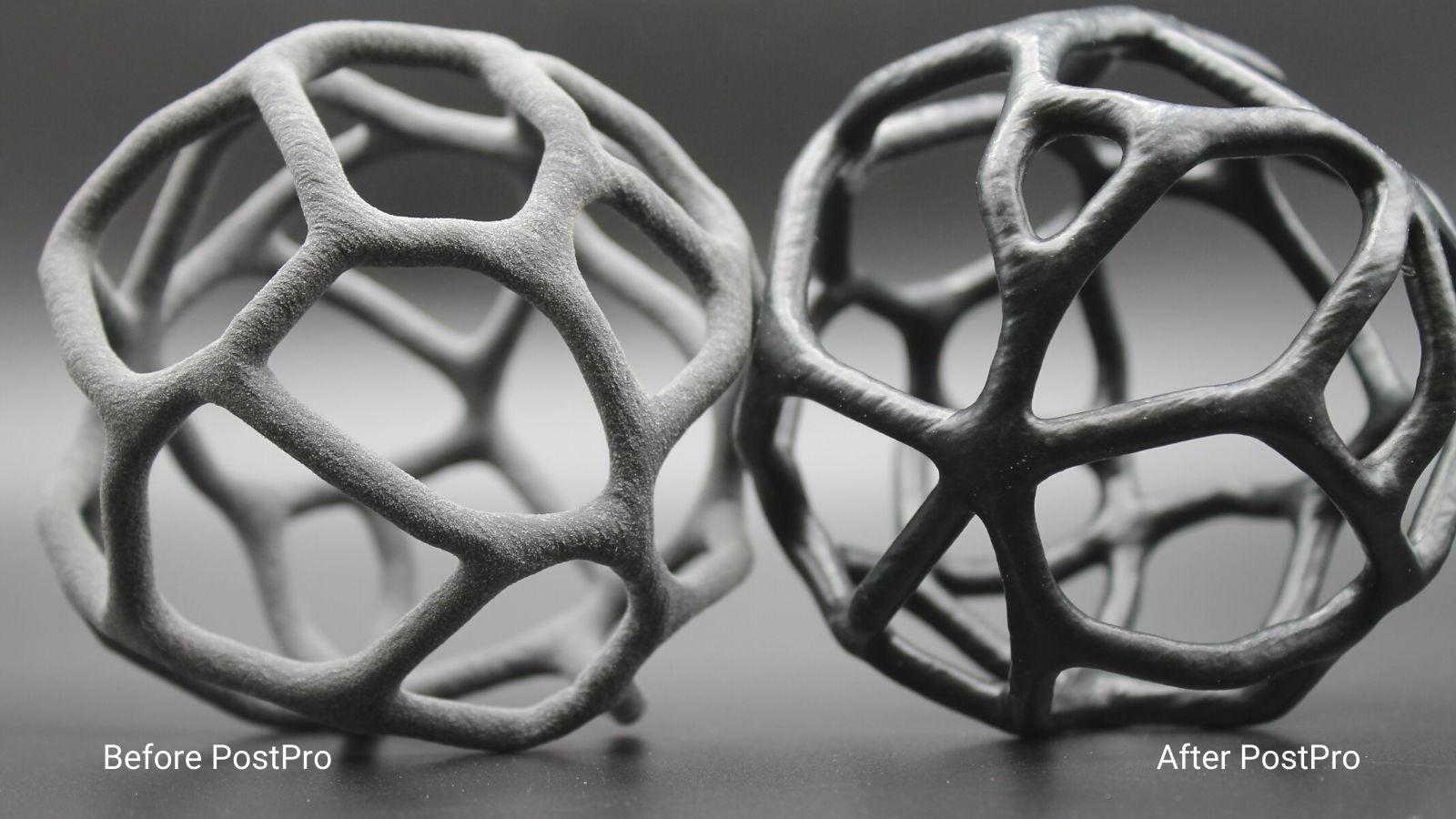

The process provides a seamless surface finish to thermoplastic 3D printed parts, by blasting parts suspended in a chamber with a highly-potent solvent to remove porosities and surface imperfections. PostPro is designed with a closed-loop system, whereby a large condenser is used to reclaim the solvent vapor after processing and pump it into a sealed, stainless steel container. Here, the solvent vapor is collected and recycled by AMT, resulting in no chemical waste.

The technology获得专利保护在2020年7月,在英国,为高度监管的应用提供了密封的表面,例如医疗部门的应用,改善了高性能应用的机械性能,并改善了消费者零件的美学。

The technology also uses no carcinogenic, mutagenic, or reprotoxic (CMR) category one chemicals, or flammable or explosive chemicals, within the process. The chemicals used in the PostPro process include a proprietary mix of organic solvents developed by theUniversity of Sheffield受到监管并批准用于医疗用途。

3D打印后处理的最新发展

Ongoing advancements in automated 3D printing post-processing technology are bringing the industrialization of additive manufacturing ever closer.

Post-processing specialist染色正在寻求减少过程时间并随着发展的发展而增加负载能力three new post-processing systems– the Powershot C Performance (cleaning), Powershot S Performance (surfacing), and Powershot DUAL Performance (cleaning and surfacing), which are engineered to complement high-volume 3D printing of industrial components on the shop floor.

Meanwhile, Polish 3D printer manufacturerSinterit已经推出了它new Powder Handling Station(PHS) which is designed to streamline and accelerate the powder recovery process during post-processing into one ergonomic platform.

Elsewhere, Chinese 3D printer manufacturer法苏恩launched a new polymer Powder Management System and External Cooling Station for its 403P system, with新的后处理单元focused on delivering speed, powder management, efficiency, and ease-of-use benefits, while SLA 3D printer manufacturerNexa3D揭开了新的Xcure后处理系统据报道,这能够在“生产量表”上后处理基于光塑料的零件。

Subscribe to the3D打印行业通讯for the latest news in additive manufacturing. You can also stay connected by following us on推特并喜欢我们Facebook。

Looking for a career in additive manufacturing? Visit3D打印作业在行业中选择一系列角色。

Featured image shows TPU 3D printed part after PostPro Chemical Vapor Smoothing. Photo via AMT.