BOFA International, a developer of fume and particle extraction technology, has published a research paper reviewing the impact of particulates and gases emitted by 3D printing processes.

该研究着眼于3D打印过程(如融合细丝制造(FFF)和增值税聚合)产生的有害空气传播污染物,以及打印机制造商如何通过整合有效的过滤系统来保护员工和产品质量的健康。

“The report highlights the importance of installing effective filtration solutions that can help capture and remove any potentially harmful emissions,” said Ross Stoneham, Product Manager – 3DP & Growth Markets at BOFA. “This will not only help protect operatives from potentially harmful airborne contaminants, but will also ensure that resulting product and the machines remain free from contamination.”

Addressing the hidden dangers of AM

Since 3D printing often involves melting and sintering, one particular health and safety concern is the emission of airborne contaminants, which can come in all shapes, sizes, and smells.

BOFA是便携式烟气提取技术的领导者,一直在开发专门针对增材制造业的产品组合产品组合,可以帮助降低与3D打印机生产的机载排放相关的风险。雷电竞充值雷电竞app下载

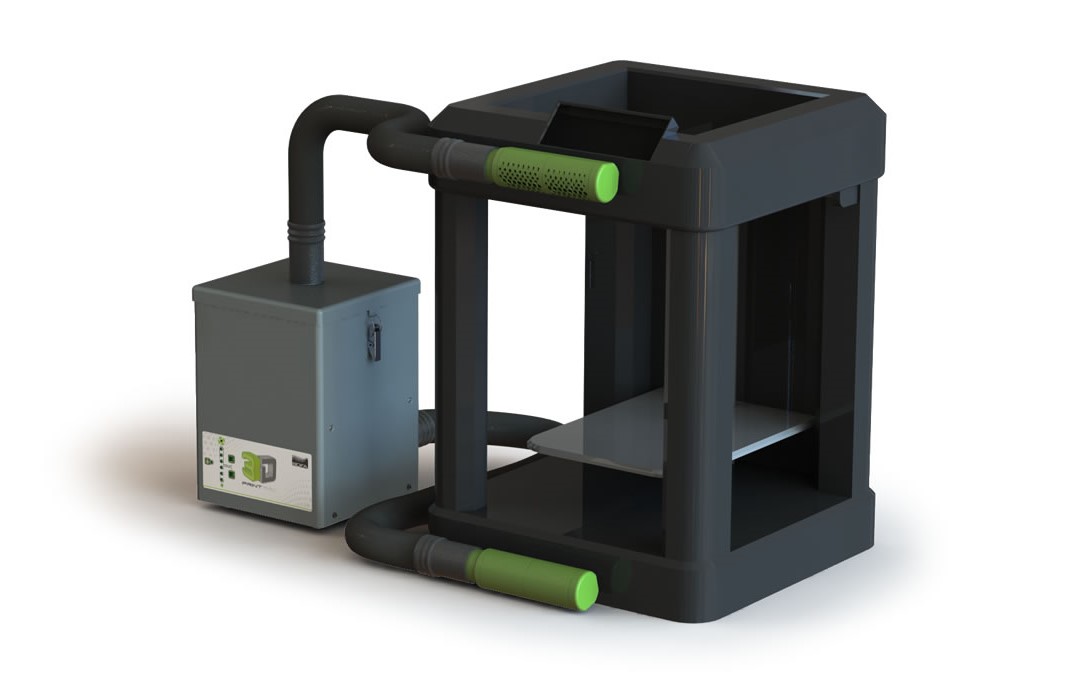

In July, BOFA signed a distribution partnership with France-based 3D printer supplierAtome3D提供它3D PrintPRO air filtration products. The devices can be integrated into third-party 3D printers in order to capture any harmful fumes and particles emitted during the printing process.

这种空气传播的污染物包括通常在纳米粒子范围内的超细颗粒(UFP),而挥发性有机化合物(VOC)的气味明显不愉快。

The detrimental effects of both types of emissions have been well-documented before, with organizations such as the国家职业安全与健康研究所(NIOSH)出版health and safety postersspecifically targeted at 3D printing.

Elsewhere, researchers fromSeoul National Universityhave previously investigated theeffect of nozzle temperature on the emission ratesof hazardous particles during FFF 3D printing, and scientists from theU.S. Environmental Protection Agency(EPA) have also studiedVOC emissions during FFF 3D printing, this time looking at composites such as carbon fiber-reinforced ABS.

BOFA’s 3D printing emissions report

BOFA的研究论文尤其关注两个3D打印过程:FFF和增值税聚合技术,例如立体光刻数字光处理(DLP)。该研究旨在更好地教育3D打印市场对3D打印机排放的影响,以更加安全和安全的方式使用它们。

Both FFF and vat polymerization processes are popular with entry-level users, however their design often requires frequent manual loading, handling and process optimization which all occur in close proximity to the printing chamber. This means there is a greater potential for exposure to airborne emissions to the operator.

除其他发现外,该报告概述了3D打印机喷嘴的温度如何显着影响FFF过程产生的粒子的体积。喷嘴温度的升高会降低印刷过程中产生的平均粒径,这意味着它们能够更容易地穿透人体,并随后对个人的健康产生负面影响。

The research paper also found that gases emitted by FFF printers also include VOCs, which can potentially cause users to experience headaches, eye irritation, skin irritation, and even occupational asthma.

Various filaments were also identified as giving off different levels of emissions. For instance, ABS filaments gave off styrene, acrylonitrile and butadiene, while PLA filaments released lactide and organic acids. However, as the odor generated by printing with PLA is much lower than with ABS, many believe the risk to be much lower or even non-existent, but the data shows there are VOCs being generated for both materials, regardless of whether a person is able to detect with their senses or not. This is why ventilating a room by opening a window is standard practice for most users.

Moving on to vat polymerization, and the photoreaction caused by heating the liquid material in its natural state has also been proven to emit airborne matter. As the printing process converts the resin into solid material, not all of it ends up in the finished part and subsequently nanoparticles are generated. BOFA’s report also focuses on the emission generated during post-processing through acts like sanding, gluing, and solvent-based finishing.

How harmful are 3D printing emissions?

在操作3D打印机时,了解与您呼吸相关的健康危害很重要。但是,尽管将这些3D打印排放分为VOC和颗粒很有用,但也应考虑颗粒和气体的复合效应。

According to BOFA, users have the right to understand the emissions from their 3D printers, and at the same time, employers should be helped in complying with their legislative responsibility to protect their employees.

该报告指出,粒子大小是特定的ly important to this understanding, as the size of the particles emitted during printing affect where in a person’s respiratory system they are deposited. The smaller a particle is, the further into the respiratory system it is able to penetrate and the more harm it can do. BOFA states the interaction of gases with the respiratory system must also be considered, as chemicals are able to be absorbed through both a user’s lungs and skin.

Mitigating the impact of emissions

In addition to educating readers on the hazards of 3D printing emissions, BOFA’s report also sets out a number of mitigation strategies to protect users.

One of the most effective protection strategies is the use of engineering controls such as fixed ventilation systems and direct extraction technologies. However, while both techniques are reasonably effective in separator the user from the hazard, they aren’t always able to completely contain the emissions produced during the process, and these can be released at the end of a build when the operator retrieves the printed part.

Administrative controls and personal protective equipment (PPE) are also ways of protecting against emissions hazards, however these simply limit an individual’s exposure rather than controlling the hazard itself. In the report, BOFA believes the greatest level of protection offered against the risk of 3D printing emissions is a specialist direct extraction (LEV) system.

Looking to the future, BOFA foresees a direct correlation between the increasing productivity of 3D printers to the amount of material printed, and in turn the amount of emissions being produced. The research paper suggests that greater adoption and maturation of additive manufacturing in the future is likely to bring greater focus on making sure the technology is safe. With this, machine and material manufacturers have a responsibility to ensure they carry out adequate testing to ensure their products are safe.

BOFA将在下周在Formnext上展示研究论文的完整发现,以及那些希望找到更多罐头的人download the paper here.

Subscribe to the3D打印行业newsletterfor the latest news in additive manufacturing. You can also stay connected by following us onTwitterand liking us onFacebook.

寻找添加剂制造业的职业?雷电竞充值访问3D Printing Jobsfor a selection of roles in the industry.

Subscribe to ourYouTube频道for the latest 3D printing video shorts, reviews and webinar replays.

特色图片显示3D PrintPro 3如何与3D打印机集成在一起。雷电竞app下载图片通过美国银行国际。