The circular economy is a concept that seeks to make optimum use of resources in order to avoid waste.

A recent flurry of sustainability announcements from 3D printing firms have revealed new eco-friendly materials, innovative methods of repurposing waste, and the launch of new projects seeking to reduce additive manufacturing’s environmental footprint.

3D Printing Industry spoke to Emma Fromberg, Course Director at theCambridge Institute for Sustainability Leadership, and Marta Redrado Notivoli, Project Coordinator ofEU-fundedresearch initiative芭芭拉和chemical engineer at theAITIIP技术中心,为了了解3D印刷行业中循环效果的洞察力,以及在未来该行业中应用的循环经济过程的机会。

Renewed efforts to combat climate change have lately been echoed on a much broader scale too, with US President Joe Biden committing the US toslash emissions by halfby the end of the decade, and UK Prime Minister Boris Johnsonurging world leaders to “get serious”ahead of United Nations (UN) climate talks later this year.

While such calls for environmental action appear to be getting louder, the failure of both government and industry leaders to match their words with action when it comes to sustainability is unfortunately nothing new. In a similar vein, while additive manufacturing is often considered a more sustainable manufacturing technology than others, according to85%的调查受访者by 3D printing software providerMaterialise, there is an industry consensus that more must be done to avoidgreenwashing the technology.

“There is no doubt that heaps of these initiatives are not genuinely solving any real issues in terms of sustainability and are merely offering more efficient material use,” says Fromberg. “However, it is often done with the best intentions.”

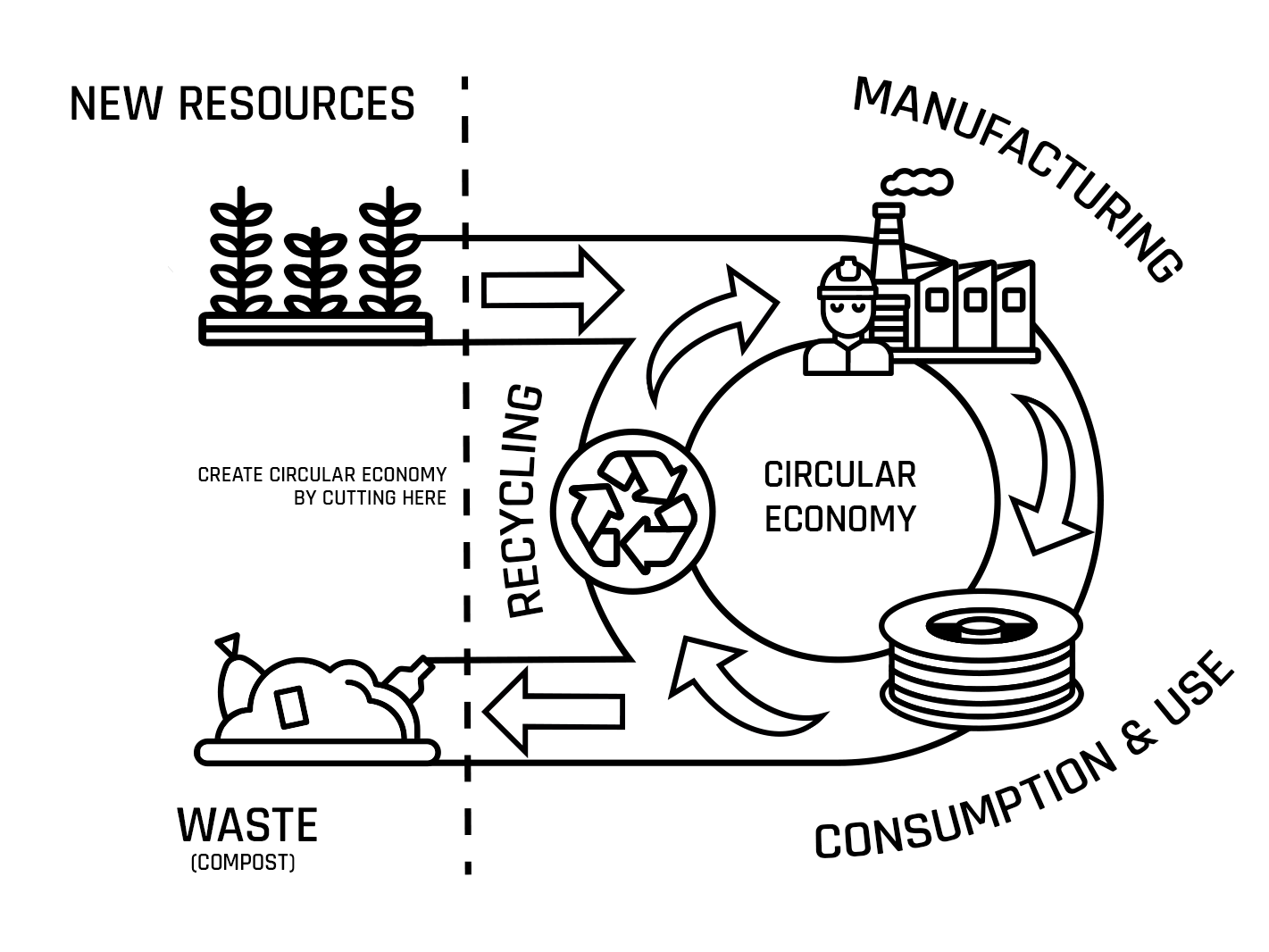

Circularity refers to an economic system with the goal of eliminating waste and the continual use of resources. The需要进一步研究into how this concept can be fully applied within the 3D printing sector has been highlighted by researchers from the诺斯博亚大学(UNIDEMI), who believe greater open-source collaboration between industry partners could eventually provide new methods of addressing theUN’s sustainability goalswith the technology.

什么是循环经济?

近年来,3D打印已在使公司能够接受分布式生产方面有效,并且这本身具有诸如提高工艺效率,减少浪费和运输减少的环境效益。

However despite these efficiency benefits, there is a growing industry consensus that far more needs to be done to improve the sustainability of the technology than is currently underway. One notion receiving increasing attention is that of the circular economy, and the role 3D printing can play in achieving circularity within manufacturing.

“As explained in the work on摇篮到摇篮by Braungart and McDonough: sustainability is not about doing less bad – we need to look at how we can do good,” says Fromberg. “It is a narrow focus to only look at the efficiency and agility of production only. We are then just using less energy and fewer materials.

“Just using less of everything is not going to be enough to address our economic, societal, and environmental crisis.”

AM内部正在进行的循环经济项目

Within the 3D printing sector alone, there are various initiatives currently underway to develop closed-loop manufacturing processes that reuse and repurpose waste materials. Within the automotive sector,Groupe Renault正在创建一个完全致力于的设施可持续汽车生产through recycling and retrofitting vehicles using 3D printing, whileFord和HPhave teamed up torecycle 3D printing waste最终使用汽车零件。

One notable project that is addressing circular economy 3D printing is芭芭拉(Biopolymers with Advanced functionalities foR Building and Automotive parts processed through Additive Manufacturing), aHorizon 2020project that brought together 11 partners from across Europe to produce bio-based materials from food waste suitable for 3D printing prototypes in the automotive and construction sectors.

之上concluding four years of research去年10月,该项目成功地开发了八种适合融合细丝制造(FFF)3D打印的新的基于生物的材料,该材料是通过提取天然染料,生物含量,抗菌剂和石榴,柠檬酸盐,杏仁壳和杏仁壳和杏仁壳和精油而创建的。玉米并将其加工成丝线线轴。

“Additive manufacturing can be used not only for prototypes but also as an opportunity to customize specific pieces,” says Redrado Notivoli. “In BARBARA, we have developed aesthetic details to technical parts.”

芭芭拉reached a technical readiness level (TRL) of five in October, and the consortium is currently planning to apply for national and European funding to reach TRL nine, which would involve upscaling the results of molecule extraction, extrusion and filament materials, and developing technology such as the consortium’s 3D printing heading device.

So far, the initiative has contributed to the growth of related industries within the bio-economy and circular economy European framework, and the next stage will be toscale up the project’s processes达到半工业级别。

“Regarding circular economy, the use of filament spools means no material waste,” Redrado Notivoli continues. “Additive manufacturing is a technology which doesn’t consume much energy, we can say it is a clean process. Residues such as plastic and fibers are used for manufacturing new biopolymers, while waste from other plastic transformation processes is reused in the form of pellets for 3D printing.”

根据Redrado Notivoli的说法,在自己的流程中拥抱循环的3D打印公司的主要好处是浪费作为资源。

“There is no waste,” she explains. “It is transformed into resources. This also means the growth of industrial synergies between additive manufacturing companies and others that could be suppliers of resources, such as waste coming from plastic, metal, agriculture, ceramics, and so on. This will imply long-term the reduction of raw material costs.”

New circular economy materials

除了上述项目外,还在开发更多可持续材料生产的方法并提高相关过程的效率。

For instance, Amsterdam-based 3D printing filament vendor回流has released a range of eco-friendly“海棒”透明材料made from locally sourced plastics, while Spain-based 3D printing materials producerRecreushas launched a flexible TPU filament that is100 percent recycled和made up of waste material from the footwear sector.

Elsewhere, circular 3D printing materials have also been developed from more obscure sources, including木质素植物细胞壁,水瓶,landfill-destined waste, and even白蚁和无聊的昆虫垃圾.

According to Fromberg, however, focusing on materials efficiency as a stand-alone solution to improving sustainability both within the 3D printing sector and beyond, is not enough.

“I would say that it can be counter-productive to overly focus on efficiency in the sustainability debate,” she explains. “Why don’t we ask ourselves: what do we want more of? I am interested in 3D printing and digital fabrication because it has the unique feature of cutting out large-scale operations and factories as a means of production and gives back individuals and communities a way to engage in the production, repair, and maintenance of their products.

她继续说:“也在Materiomby Alycia Garmulewicz and Liz Corbyn, there is an interesting field of possibilities opening up around using hyper-local (natural) materials for digital fabrication. All of these ideas together might help us to re-image a resilient and democratic system for production.”

在AM中发展进一步的循环经济过程的潜力

When asked where she foresees the greatest opportunities for successful circular economy processes to be applied within the 3D printing sector, Fromberg stated that additive manufacturing technologies have the potential to create a “variety of opportunities” for rural areas and emerging economies, in particular.

“Accessibility of means of production and the economic opportunities that are accompanied by the distributed nature of these technologies could have a profound impact on these areas, adding to equality, working conditions, and social fairness, for example,” she says. “I find this part of the discussion is often overlooked since the AM debate seems to be mostly based in Western urban regions and about materials efficiency.”

但是,她提供的是,西部城市地区的城市地区不仅仅是材料效率:“例如,围绕制造商和fablab,可以将社区联系起来,并支持个人始终保持其产品的价值。

“将这些类型的空间与工具库相结合也可能是一种增加已经存在的产品的实用性的方式,同时将它们连接到便利的维修和维护方法。”

3D printing: Sustainable or not?

虽然应倡导和鼓励新的“环保”材料和改进的循环生产工艺,但在生产系统的所有领域都需要考虑和应用添加剂制造业的可持续性,以激发有效和有形的变化。雷电竞充值

“业务经理,设计师,工程师,salespeople: they are all used to looking at their own part when a service or product is being rolled out – not the wider system of the production and the use of the product and who benefits from it,” she says. “More effective and genuine sustainable solutions require all these stakeholders to work together and look at the sustainability issue and the solution holistically.”

Indicating that individual triumphs aren’t enough to make the sustainability strides the 3D printing sector desires, Fromberg offers that a much greater collaborative approach between all levels of the supply chain is necessary.

“Even if you would not emit any carbon emissions at all, I would consider it not sustainable if you do not explore how everyone and everything can benefit from whatever you produce,” she explains. “I am looking forward to seeing real creative solutions that celebrate the unique features of 3D printing and digital fabrication in this space.”

It seems fair to surmise that while the development of new eco-friendly materials and the launching of various projects seeking to reduce additive manufacturing’s environmental footprint are positive steps in the sector’s march towards greater sustainability, there is still a long way to go before 3D printing becomes a fully circular manufacturing technology.

For this to become reality, it will require all parties active within the design and manufacturing process and supply chain to play their part in achieving a sustainable production model beyond simply maximizing process and material efficiencies.

Subscribe to the3D Printing Industry newsletterfor the latest news in additive manufacturing. You can also stay connected by following us onTwitter和liking us onFacebook.

Looking for a career in additive manufacturing? Visit3D Printing Jobsfor a selection of roles in the industry.

特色图片显示Aitiip在Barbara项目中完整的筋膜原型。使用的材料(从左到右):柠檬色素,柠檬香气,杏仁壳,石榴颜料。图片通过芭芭拉(Barbara)。