Industrial 3D printer manufacturerDesktop Metalhas announced the acquisition of hydraulic and fluid power system developerAidro。

作为一个自称“先驱”的添加剂的汇率政策uring in the fluid power sector, Aidro specializes in turning outdated hydraulic designs into consolidated, lightweight, 3D printed alternatives. Having been bought by Desktop Metal, the firm is now seeking to harness any extra backing it can get, to improve its penetration within 3D printing’s emerging oil, gas, energy and industrial markets.

“我们很高兴与台式金属联合起来,” Aidro业务发展副总裁托马索·蒂雷利(Tommaso Tirelli)解释说。“这种合作伙伴关系将使我们能够继续投资于扩大下一代液压解决方案的增材制造,这些解决方案破坏了石油,天然气和航空航天等大规模行业。”雷电竞充值

Adopting ‘Aidrolic’ 3D printing

Since it was founded in Northern Italy back in 1982, Aidro has established itself as a manufacturer of the hydraulic components used within the high-tech industrial, energy and aerospace sectors. Until just four years ago, the company’s production process revolved around ordinary industry-standard techniques, but in 2017 it changed tack, when it began to additive manufacture many of its lines.

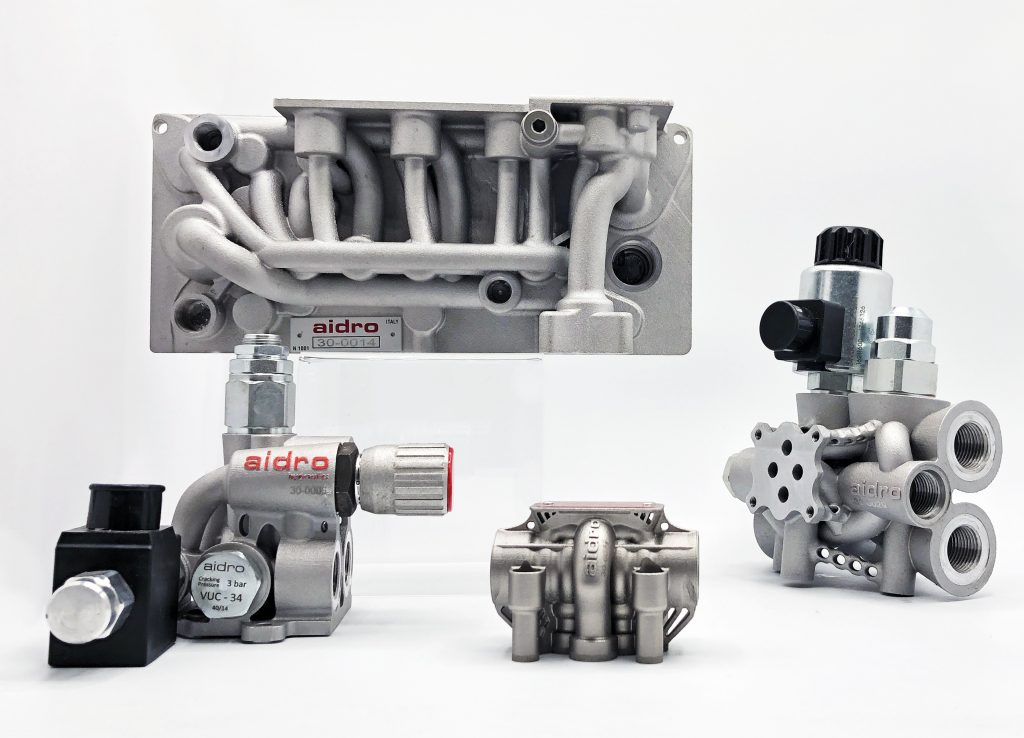

自从采用LBPF生产这些液压零件以来,Aidro说,它不仅能够减少其交货时间,而且可以将其定位为“内部渠道”,以优化其性能。开关后,它现在3D打印了从液压阀块,线轴,高压歧管和热交换器到钢制手表的所有内容,同时进行了按需以及客户规格。

Aidro also leverages the technology to manufacture industry-specific parts like rotary valve bonnets and servofly T4/1 adapters, which are targeted towards the energy, maritime and aerospace sectors respectively. The latter, which are SLS rather than PBF 3D printed, found fame in August 2019 when they were used to帮助残疾飞行员再次飞行,充当驾驶舱“插电”控制系统。

Elsewhere, the company has continued to invest in its additive manufacturing facilities, packing its dedicated division with printing and scanning technologies for producing spares and prototypes on-demand, but following its acquisition by Desktop Metal, Tirelli says that it now has the resources needed to take the “next step in its AM evolution.”

“AM offers benefits unmatched by conventional manufacturing, and once Aidro realized its advantages, we quickly allocated resources to develop expertise and take advantage,” said Tirelli. “With access to Desktop Metal’s scale and industry-leading AM 2.0 technology portfolio, including its volume production-focused metal binder jetting solutions, we’re thrilled at the growth potential for Aidro.”

Desktop Metal’s growth continues

之后与Trine收购合并25亿美元2020年12月,桌面金属上市NYSE, in a move that saw it raise $580 million in funding. Leveraging its newfound capital, the firm has since gone on to acquire multiple subsidiaries under the guise of its wider ‘AM 2.0’ strategy, with the stated aim of opening further applications to its 3D printing users.

Thus far, Desktop Metal’s highest-profile purchase has beenExone,它同意以5.75亿美元的价格购买in cash and shares just last month. Once completed, the deal will see two of the sector’s biggest binder jetting firms join forces, and at the time it was agreed, Desktop Metal’s CEO Ric Fulop said that it would help “increase the penetration of the technology.”

Binder Jetting抛开,该公司也购买了其他3D打印区域acquiring EnvisionTEC for $300 million去年进入DLP市场接管Adaptive3Dto improve its material portfolio. The firm has also invested heavily in expanding into the healthcare sector,获取Beacon Bioas well asestablishing Desktop Health, a subsidiary it sees as a key future revenue driver.

With its acquisition of Aidro, however, Desktop Metal is not just buying its facilities, but inheriting its expertise, as well as its ISO9001 and AS/EN9100 certifications, which are particularly relevant within aerospace. According to Fulop, the deal therefore allows Desktop Metal to better support its clients with “proprietary design and application know-how,” in what he describes as “killer applications for AM 2.0.”

“Aidro brings a talented team with decades of experience in hydraulics and fluid power systems and a passion for leveraging AM to deliver performance advantages,” concluded Fulop. “We’re excited about the acquisition and look forward to advancing AM 2.0 for high-volume production of hydraulics, valves, fluid power systems, and many more end-use parts in development with Aidro.”

优化液压设计

使用3D打印,许多液压系统制造商开始确定将内部渠道集成到其产品中的新方法,从而改善其体重和性能。今年早些时候,流体电力系统生产商Domin通过采用Renishaw金属3D打印,它已经能够实现这一目标并制造高性能伺服阀。

Designed to control hydraulic fluid by turning signals into pressure, the devices were built to be 25% more powerful than conventional valves, while being around a quarter of the size. The redesigned units also cost a third less than normal, and have the potential to save up to one tonne of CO2, making them seem eco-friendly, in a fluid power sector that accounts for 300 million tonnes of the gas per year.

早些时候,2020年3月GKN Additivealso reported3D printing a hydraulic adapter block,它重新设计的重量比传统制造的对应物少80%。通过采用设计添加剂制造(DFAM)原则,该公司能雷电竞充值够减少构建所需的材料量以及其成本,同时改善其整体功能。

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D打印行业通讯or follow us on推特or liking our page onFacebook。

为了深入研究添加剂制造,您现在可以订阅我们的雷电竞充值Youtubechannel, featuring discussion, debriefs, and shots of 3D printing in-action.

您是否正在寻找添加剂制造业的工作?雷电竞充值访问3D打印作业在行业中选择一系列角色。

Featured image shows an Aidro engineer using an EOS M290 3D printer. Photo via Aidro.