Austrian engineering firm and OEM startupIncus GmbHhas continued to grow the customer base for its flagshipHammer Lab35metal 3D printer throughout 2020, having entered series production of the machine after its first shipment in March last year.

The printer is based on the lithography-based metal manufacturing (LMM) process developed by Incus for the manufacturing of prototypes and small-scale components of metal injection molding (MIM) quality. Now, the firm is looking to continue scaling up production of the Hammer Lab35 throughout 2021.

“Despite this challenging year, we had great collaborations with customers and have proven the LMM has the potential to increase performance and to reduce costs for small and mid-scale production, as well as for manufacturing parts featuring complex geometries,” said Dr. Gerald Mitteramskogler, Incus CEO. “Our team is extremely proud to have added 3D printing of metals with lithography to the manufacturing landscape. We highly appreciate the trust and patience of our first customers that have been helping to develop our product and our company.”

“We still have a journey ahead to scale up to mass-production, but we are eager to continue this path in 2021.”

Incus and LMM

Incus was founded in 2019 in the R&D lab of ceramic 3D printing specialistLithoz, a spin-out ofTU Wein. Incus is a member of theAM Ventures portfolio, anaward-winninginvestor in 3D printing technologies.

Incus’ LMM technology is based on vat polymerization techniques such as stereolithography (SLA) and Digital Light Processing (DLP), although differs from these processes by curing materials that contain metal particles. The printed parts are then debound and sintered to create solid metal parts in a similar manner to the likes of metal binder jetting and fused filament fabrication (FFF)-based techniques that usea metal-infused filament.

Incus’ LMM technology is able to process materials containing metal particles as small as 20 µm in size, and is capable of working with “unweldable” metals. The firmlaunched its flagship metal 3D printerbased on its LMM process, the Hammer Lab35, atFormnext 2019.

The Hammer Lab35

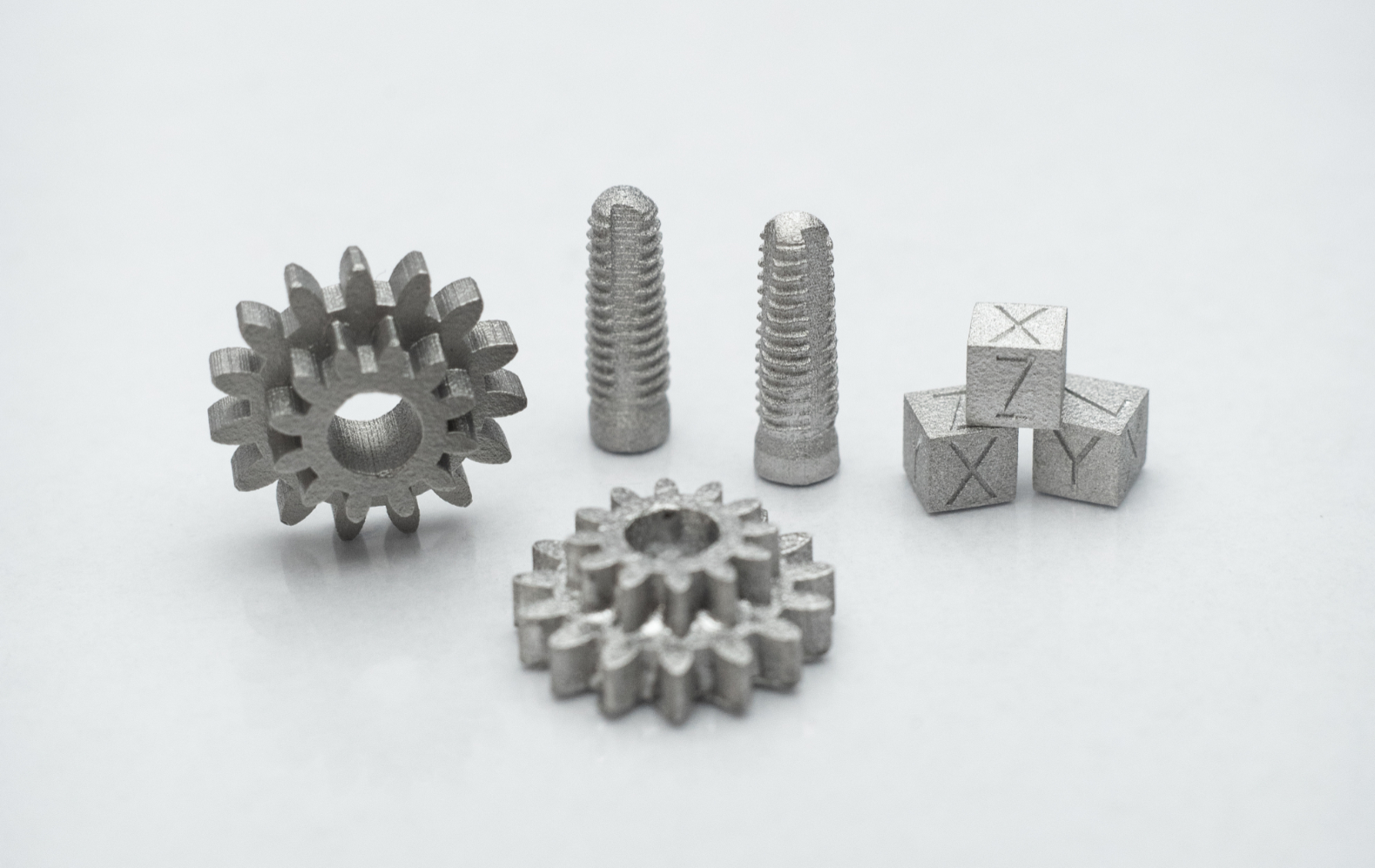

Incus’ metal 3D printer has been designed to deliver high feature resolution, surface aesthetics, and mechanical part properties for parts weighing less than 200g, which Incus claims is the first time this combination has been achieved within metal 3D printing.

The Hammer Lab35 features a print speed of up to 100cm3/hand a lateral resolution of 35 µm to produce high quality parts. According to Incus, the machine is designed to meet the manufacturing industry’s increasing demand for 3D printing processes capable of delivering intricate geometries for functional prototypes and pre-series manufacturing.

Two Hammer Lab35 3D printers are currently installed at the Institute for Precious and Technology Metals at theUniversity of Pforzheimand its spin-off company, metal engineering firmMetshape. Pforzeim has been testing and reviewing both the LMM process and the printing system since the development of the Hammer Lab35 began, and are continually working to develop new materials and applications. The feedback received from the team at Pforzeim has aided Incus in adapting and improving the machine and its feedstocks.

Incus shipped its first series of 3D printers in March 2020, and has since entered serial production of the machines as it has continued to grow its network of customers and partners throughout the year. As the firm looks ahead to 2021, the next step is to scale up mass production of the Hammer Lab35.

Subscribe to the3D Printing Industry newsletterfor the latest news in additive manufacturing. You can also stay connected by following us onTwitterand liking us onFacebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit3D Printing Jobsfor a selection of roles in the industry.

Featured image shows the Hammer Lab35 in use. Image via Incus GmbH.