Subscribe to ourYouTube channelfor the latest 3D printing video shorts, reviews and webinar replays.

Private US aerospace firmLauncher它在A系列融资一轮中筹集了1,170万美元,因为它试图提高其第一款轨道发射车的开发,即“发射器灯”火箭。

该公司希望在th显著增长e lead-up to the rocket’s 2024 launch date, and reportedly plans to more than double its number of employees by the end of this year.

As part of the announcement, Launcher also unveiled its new logo that is designed to symbolize the firm’s orbital rockets, high-performance engines, and the Earth.

通过AM优化火箭发动机性能

Since its establishment in 2017, Launcher has continually leveraged 3D printing to upgrade the performance of its rocket engines. The company’s goal is to create efficient, optimal cost rockets capable of delivering small satellites to space.

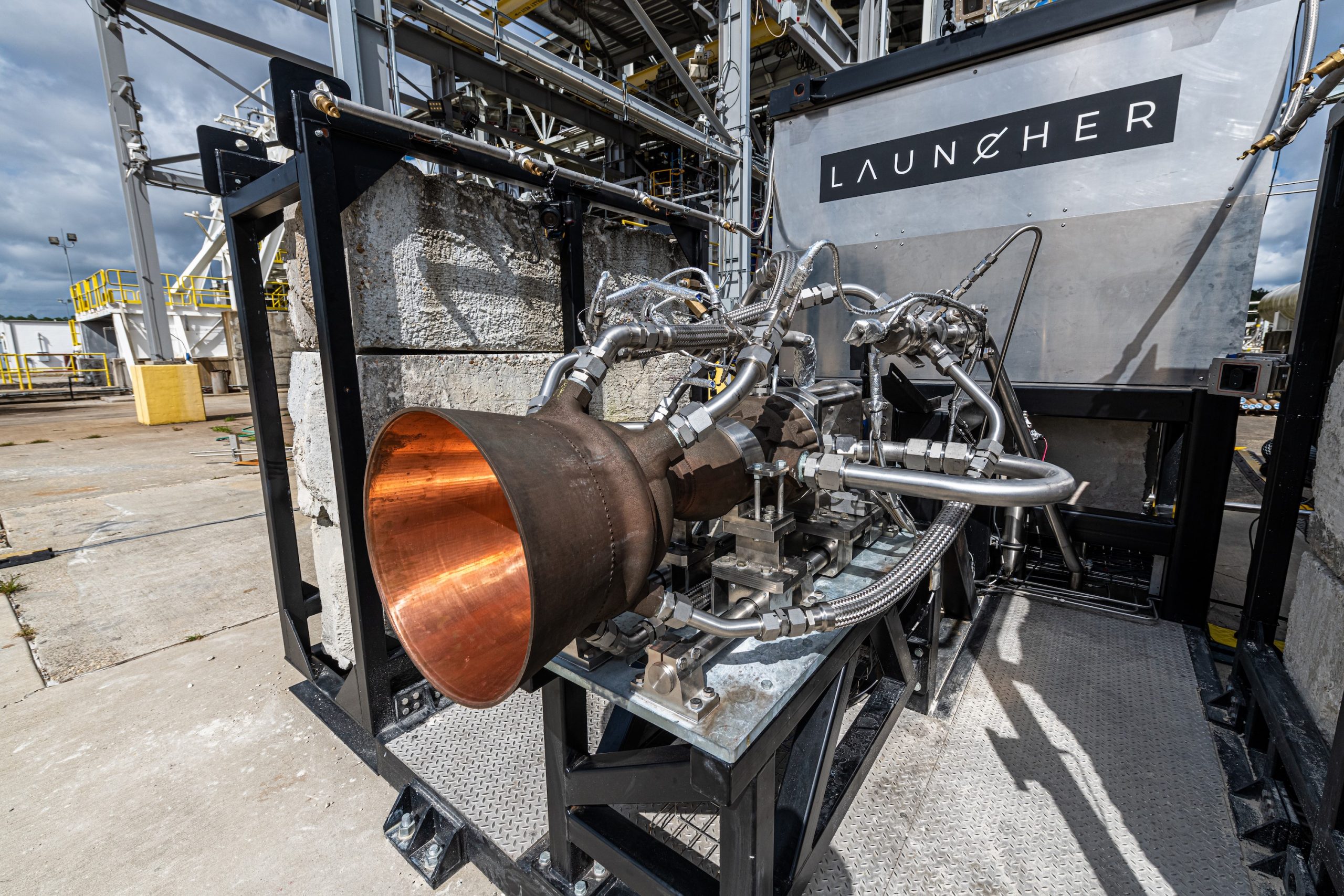

After being awarded a$1.5 million Space Force contractin 2019, the firm embarked upon developing 3D printed components for its E-2 engines, producing arocket combustion chamberthat was reportedly thelargest part of its kind, measuring 860mm tall and featuring a 410mm exit nozzle. The combustion chamber was 3D printed in a single piece using anM 4K 3D printerprovided byEOSsubsidiaryAMCM。

Launcher’s E-2 engines are 3D printed in high-performance copper alloy and purportedly require less propellant to get to orbit, in theory allowing the company to deliver more satellite cargo per rocket and subsequently offer a lower price than its competitors.

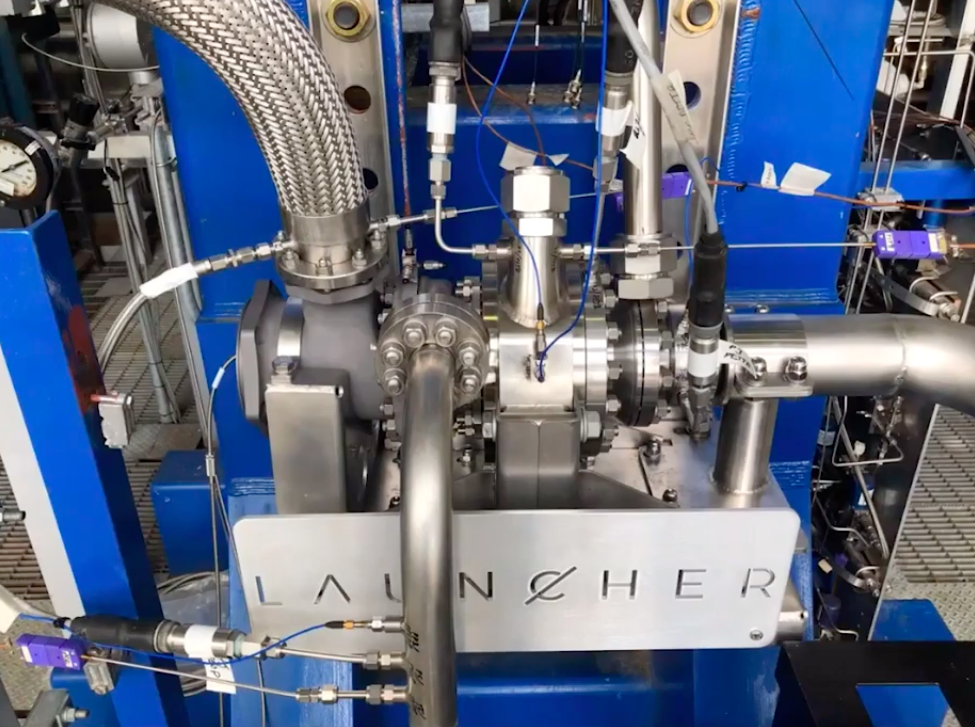

Just last month, Launcher teamed up with 3D printer manufacturerVELO3Dand simulation software firmAnsysto optimize the design of another performance-critical component in its E-2 rocket engine, aheritage liquid oxygen (LOX) turbopump。Having undergone extensive engine tests at NASA’sStennis Space Center, the turbopump will be integrated into the “Launcher Light” rocket prior to launch.

Accelerating rocket development

In its first few years, Launcher prided itself on being a lean company with few employees and low overhead costs, expending around $1.5 million per year.

However, in anARS Technica的访谈, Launcher founder Max Haot said the company will need to up this spending to some $10 million a year in order to reach orbit by 2024 with its “Launcher Light” rocket. He also revealed the company will need to scale up to around 150 employees by its first orbital flight, with plans to increase employee numbers from around 30 to 70 by the end of 2021.

Taking into account the $11.7 million Series A funding announced this week, Haot will attempt to achieve this scale up with a budget of $50 million and an additional round of funding expected to be completed by early 2022. As part of the Series A funding, Haot has invested $5 million of his own money from the sale of hisMevocamera business to software and peripheral manufacturerLogitech。

发射商的增长野心还使该公司今年早些时候在加利福尼亚州霍桑的航空航天枢纽将总部从纽约转移到24,000平方英尺的设施。

竞赛到太空

竞赛到太空is continually hotting up between private aerospace firms using 3D printing to develop rocket engines with enhanced in-flight capabilities, and this year alone has already seen several notable developments.

2月,英国航空航天公司Orbextasked AMCM with building the largest industrial 3D printer in Europe to enable the company torapidly print rocket engines in-house。Once complete, the printer is expected to enable the printing of more than 35 large-scale rocket engine and main stage turbopump systems each year.

Orbex收到后,希望在2022年开始其第一次轨道发射planning permission for its spaceport在2020年8月的苏格兰高地,这是英国第一个获得许可。

Meanwhile, in March California-based aerospace firmRocket Labannounced plans to go public on the Nasdaq stock exchange in a move that saw the companyvalued at $4.1 billion。该公司还取消了其最新的开发创新,可重复使用的中子发射车,该车将配备八吨的有效载荷,并有能力提高所有卫星预测的90%以上的预测,直到到达结束时该公司声称,十年。

Elsewhere,NASA授予$3 million contract到3D印刷火箭制造商相对性空间to launch small satellites into orbit, and US propulsion system manufacturerAerojet Rocketdyne宣布其升级的RL10火箭引擎已成功通过了NASA热火测试。The engine is equipped with a 3D printed injector and combustion chamber and will power the company’s Vulcan Centaur launch vehicle as part of upcoming exploratory space missions.

Subscribe to the3D Printing Industry newsletterfor the latest news in additive manufacturing. You can also stay connected by following us onTwitterand liking us onFacebook.

Looking for a career in additive manufacturing? Visit3D Printing Jobsfor a selection of roles in the industry.

Subscribe to ourYouTube channelfor the latest 3D printing video shorts, reviews and webinar replays.

特色图片显示Launcher’s AMCM-3D printed combustion chamber. Photo via AMCM.