Researchers fromETH Zurich和Nanyang Technological University(NTU) have developed a new 3D printing technique capable of producing nanoscale metal parts.

基于电化学方法,该过程可用于制造直径25纳米的铜对象。参考,平均人毛在75微米时厚约3000倍。

According to the research team led by Dr Dmitry Momotenko, the new 3D printing technique has potential applications in microelectronics, sensor technology, and battery technology.

Adapting electroplating for additive manufacturing

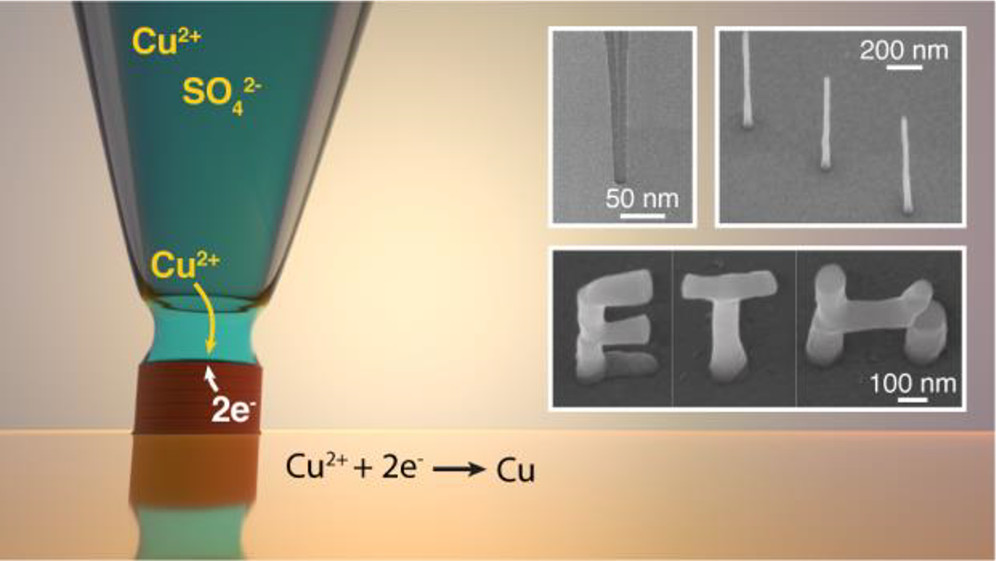

The ETH/NTU nanoprinting approach is actually based on the process of electroplating, a well-known metal coating technique used in the world of manufacturing. To electroplate a part, manufacturers suspend positively charged metal ions in a salt solution. A negatively charged electrode is then added to this liquid solution, which causes the ions to combine with the electrons in the electrode and form neutral metal atoms. The atoms are deposited as a coating on the electrode and slowly form a solid layer on the surface.

Momotenko adds, “In this process, a solid metal is fabricated from a liquid salt solution – a process that we electrochemists can control very effectively.”

The nanoprinting process operates on the exact same premise, whereby a tiny pipette is used to deposit positively charged copper ions onto a negatively charged print surface. In this case, the team used a nozzle tip just 1.6 nanometers wide, meaning only two copper ions could pass through at a time. This, combined with several electrochemical printing parameters, allowed the team to closely control the diameter of the printed structures. The paper reports that the smallest of the printed objects came out at just 25 nanometers wide (195 copper atoms).

On the other hand, conventional powder-based metal 3D printers are typically only capable of reaching micron-level resolutions, which are still several thousand times larger than those in the present study.

Momotenko解释说:“我们正在使用的技术结合了两个世界 - 金属印刷和纳米级精确度。”

Applications of metal 3D nanoprinting

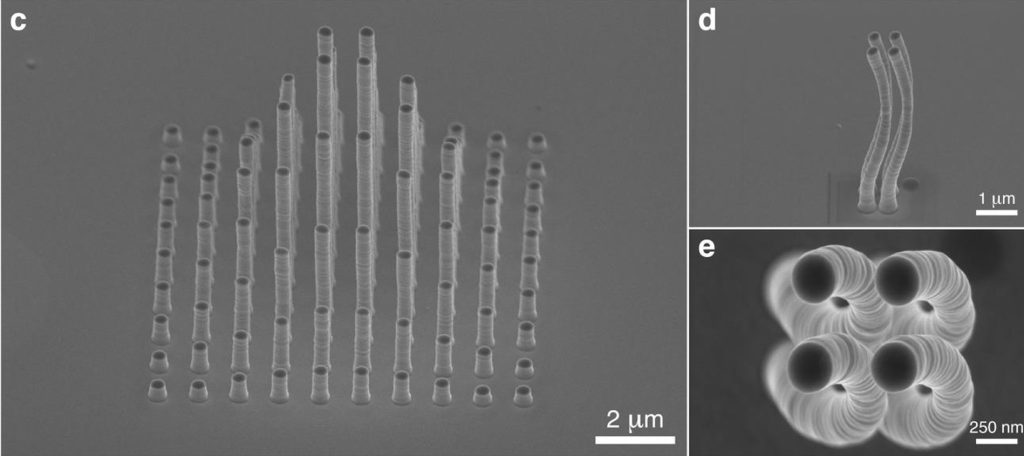

Interestingly, Momotenko’s team found that their 3D printing process was able to fabricate a wide variety of object types, including vertical structures, horizontal structures, inclines, and even spirals. The powerful approach lends itself to a whole host of novel applications such as more efficient energy storage devices, microelectronics, and even 3D printed catalysts for chemical production purposes.

As far as future work goes, the researchers are currently working on applying the technique to 3D print more compact lithium-ion batteries. The designs are set to feature increased surface areas on the electrodes and shorter distances between the electrodes, all in a bid to speed up the charging process.

Further details of the study can be found in the paper titled ‘将电化学三维印刷带到纳米级’.

The research sphere is often home to some of the most innovative 3D printing techniques around. Back in October, researchers at拉夫堡大学developed a novel hybrid 3D printing technique that allows them to change the properties of printed parts over time, enabling a new form of 4D printing. NamedMaterial Treatment Extrusion Additive Manufacturing (MaTrEx-AM), the approach combines conventional extrusion-based 3D printing with a chemical treatment.

Elsewhere, atFraunhofer IWS, scientists revealed the testing of a3D printing system that could be up to “a thousand times faster”than current mirror-based laser manufacturing technologies. Built around a high-powered 13 KW ‘Dynamic Beam Laser,’ the institute’s setup is said to be capable of rapidly generating different energy distribution patterns, and precisely printing the most demanding of materials.

订阅3D Printing Industry newsletterfor the latest news in additive manufacturing. You can also stay connected by following us on推特, liking us onFacebook, and tuning into the3D Printing Industry YouTube Channel.

寻找一个职业在加法制造吗?雷电竞充值6sit3D Printing Jobsfor a selection of roles in the industry.

Featured image shows the new 3D printing technology. Image via ETH Zurich.