The2021 3D印刷行业奖候选名单愿意投票,现在就有发言权。

As the 2021TCT 3Sixty show在伯明翰,3D印刷行业结束了,总结了贸易展览会的关键要点。

尽管以前的版本有些缩小版本,但该活动以专业且管理良好的活动欢迎NEC的访客,这是他们首次涉足面对面的演出。

Of the hundred or so exhibitors, many of the big names in additive manufacturing were present, and a busy conference schedule of some 80 presentations across the three days inspired discussions around the adoption and optimization of additive manufacturing technology.

Recent launches on display

Despite the lower exhibitor numbers, there was still plenty to see at this year’s show. One eye-catcher came from 3D printing hardware manufacturerE3D, which launched its new FFF 3D printer hotend range,RapidChange Revo, on the first day of the event. The system is designed for easy integration into any FFF 3D printer and enables users to switch their 3D printer’s nozzles without the need for complex tools or hot tightening.

The RapidChange Revo range initially includes the Revo Micro and Revo Six, with the former weighing only half as much asE3D’s widely popular V6 hotend。To change their Revo nozzles, users need only unscrew the old hotend with their fingers and screw a new one in its place.

E3D还公布了5月份提交的一些IP(即将推出的黑曜石喷嘴)的位置 - 很快就会出现更多细节。

Elsewhere, the recently unveiledLC Opus LCD 3D打印机from 3D printer and materials manufacturerPhotocentricwas on display. Based on the firm’s LCD 3D printing technology, the desktop 3D printer is slated to be the company’s most rapid LCD machine to date, and is suited to a wide array of applications spanning dental models to turbines.

美国3D打印机制造商3D系统展示了其材料投资组合的最新成员VisiJet Wax Jewel Red,在它的展位。该材料专为精美的珠宝铸造而设计,以各种复杂的3D印刷蜡铸件展示,并经过精心设计,旨在为珠宝工匠和铸造房屋提供成本,效率和设计优势。

3D printing software developerMaterialiseshowcased the最新版本的魔法软件, and also displayed its long-awaitedBluesint PA12technologythat uses 100 percent reused powder for SLS 3D printing.

同时,捷克3D打印丝生产商Fillamentum展示了其第一个100%可生物降解的灯丝,用于3D打印,非上油, at the show,首次于3月推出今年,以及AM解决方案, part of the罗斯勒集团,展示了其下一代S1后处理系统的功能。

虽然并不是严格的新发布,但很有趣的是系统的升级, offering two-in-one de-powdering and cleaning of 3D printed components.

同样在展会上,清洁和表面精加工系统制造商DyeMansionmade several UK-based partnership announcements.激光线was designated the firm’s newest authorized reseller for the UK, while the UK’sDigital Manufacturing Centre(DMC) has added a DyeMansionPowerfuse S工业蒸气抛光系统用于后处理。

激光线will offer the fullStratasys以及基于Stratasys H350和染色体打印到生产平台的染色体参考架构,出生于strategic alliance between the two companies五月宣布strengthened earlier this month。激光系已成为英国的第一批染色器转销商,提供了两种新StratasysSAF粉床技术和完整的染色工作流程。

展望未来,DMC还将严重依赖Stratasys的SAF技术,并安装Powerfuse S将成为第一个供应商提供地层sys-DyeMansion reference architecture, including the H350, Powershot C, Powershot S, Powerfuse S, and DM60 systems.

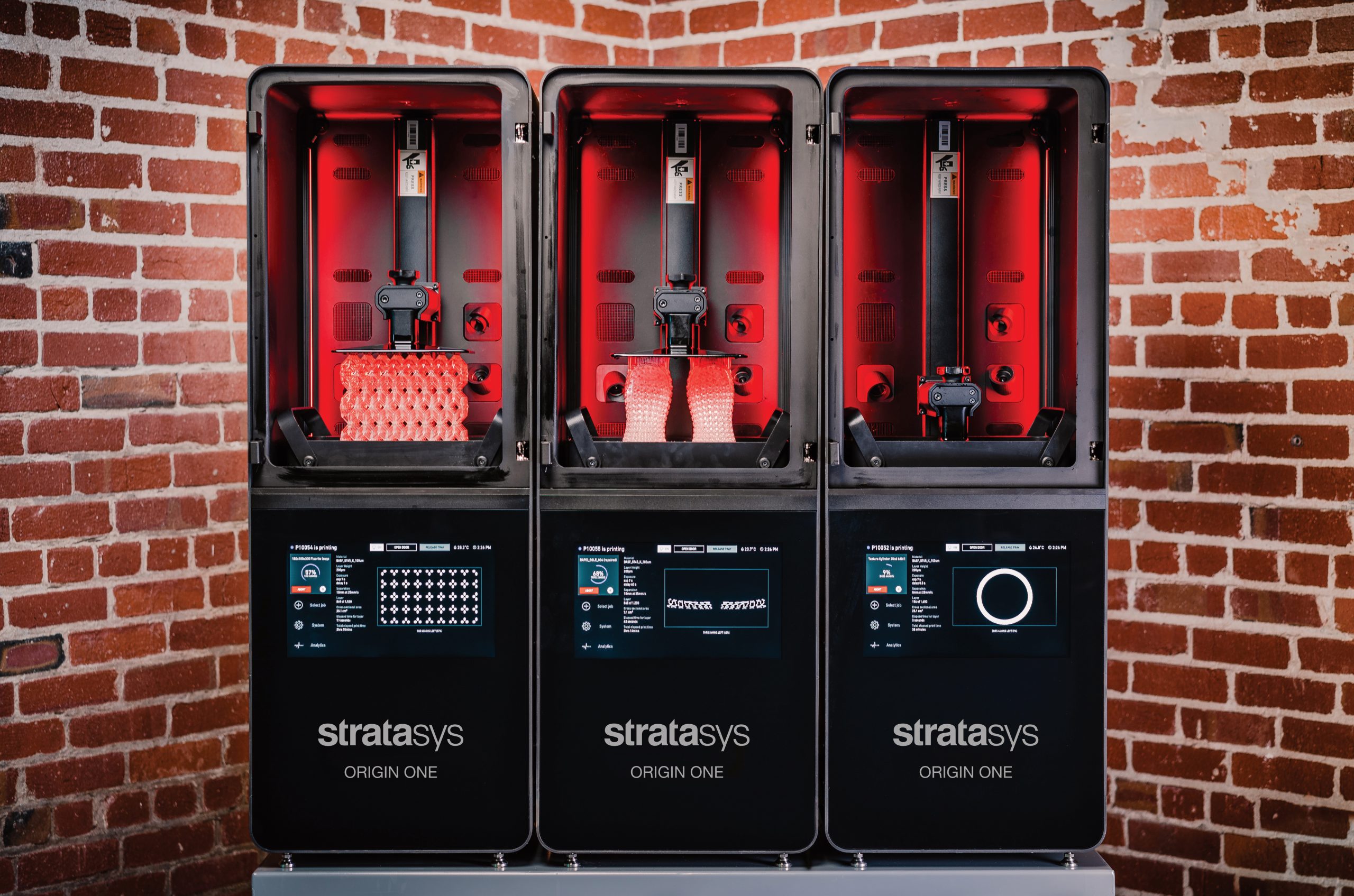

Laser Lines销售总监Mark Tyrtania表示:“随着H350和Origin One P3的增加,Strat雷电竞充值asys的增材制造技术迅速进入了真正的生产环境。”“为了提供真正可行的生产解决方案,我们需要查看整个工作流程 - 从零件的3D打印到完成的文章。

“通过将产品范围添加到我们的投资组合中,我们现在可以为客户提供端到端的后处理交钥匙解决方案。”

德国电子3D打印公司在TCT展厅的其他地方Neotech AMT正在展示其技术的最新应用。与董事总经理马丁·海奇(Martin Hedges)交谈,这似乎是该公司创新的时期“完全添加”电子设备,并为4D机甲系统开发可扩展的混合3D打印过程,作为该系统的一部分EU-backed AMPERE project。

Hedges also alluded to another interesting development in the pipeline regarding recyclability and circular economy gains within 3D printed electronics, with more details on this project to follow.

Stratasys’ Andrew Langfeld on software, market growth, and industry consolidation

Fresh fromunveiling a slew of announcementsat快速 + TCT本月早些时H350和原点一个系统and the addition of additive manufacturing software developerAMFGto itsGrabcad软件合作伙伴计划。

我与Stratasys总裁Andrew Langfeld在伯明翰活动中坐下来,讨论该公司对材料创新和软件集成的重要性,及其在来年的增长计划。

“The new materials is one thing, but a significant thing,” he says. “With the new technologies, we are trying to work with the big firms and vendors on material partnership programs to accelerate their development and bring more certified parts and materials to the market.”

The company’s recent expansion of its 3D printing technologies plays a key role in this aim, and in enhancing its customers’ options to produce use-case-specific additive manufactured parts.

“Historically, we have been a Polyjet FDM company where we could truthfully claim we are the market leader in the industrial segments,” Langfeld explains. “But now we realize that there is the growth potential obviously for Polyjet FDM for prototyping and jigs and fixtures applications, for example, but we needed additional technology in order to also address the manufacturing production orientated market, and that comes with the right technologies.”

As such, Stratasys has had a busy time recently on the merger acquisition front, havingacquired DLP machine manufacturer Origin例如,去年年底。现在,兰菲尔德认为该公司在产品开发方面拥有大部分基础。

“我们为产品开发生命周期的每一步都有正确的解决方案,从原型,设计和功能原型到生产地板的夹具和固定装置,一直到加上零件,认证,这再次说明了我们正在释放的材料,“ 他说。“我们希望为相关的用例提供正确的材料,因此我们在产品开发生命周期的所有步骤中提供此产品,现在我们需要为工作流动自动化和软件寻找其他改进,因此这就是什么我们现在正在关注。”

The addition of AMFG to the GrabCAD partner program is part of this endeavor, and going forwards Stratasys will continue to look for further software partnerships to make it easier for customers to deploy its technologies within their specific production environments.

兰菲尔德继续说:“整合将是至关重要的。”“因为一方面,您需要拥有合适的技术,使您拥有正确的量,时间,零件质量和每零件的成本,但您需要采用合适的技术,因为您需要越来越多地部署添加剂的真正突破点。还需要确保您拥有正确的工作流程。”

Langfeld also views technologies such as artificial intelligence (AI) and machine learning as being critical to the integration and adoption of 3D printing for production, stating “it is crucial that we integrate as much of the latest technologies outside of additive manufacturing into the workflow of the products we have, in order to make it state-of-the-art.”

当被问及Stratasys医疗部门对公司未来的愿景的重要性时,Langfeld确认这仍然是一个重点,这证明了其最近发布的J5 Medijet 3D打印机。

“And with that comes again the specific focus on relevant materials development, the certifications that are required, and the workflow integration into hospitals, for example,” he says. Ultimately, Stratasys is looking to integrate its medical 3D printers into clinical settings much as CT scanners have become a part of the patient-care workflow.

Regarding growth, Langfeld offered that Stratasys’ core PolyJet and FDM technologies are still experiencing healthy demand, bolstered by the releases of the F770, J35, and J5 MediJet systems. Regarding the EMEA region, he holds the “reasonable vision to double the business in the coming years”, in light of the potential gains the firm could yield from its recently acquired stereolithography and other verticals. “I think it is a no-brainer that we should be able to address many more markets and applications than we have been addressing in the past, that growth would be a natural result,” he adds.

兰菲尔德(Langfeld)最近观察到不仅在Stratasys内部,而且在3D印刷领域中都有重大的创新,这是“在经典添加剂制造技术之外”,尤其是在软件,工作流集成和部分识别范围内,这有助于增强生产环境中的采用。雷电竞充值这项创新的大部分是由新进入市场的新进入者驱动的,他确定的将导致该行业内的合并期。

他说:“看看市场上的那些基于资金,SPAC或IPO的球员是否会提供他们做出的承诺,这将非常有趣。”“如果他们做出这些承诺,它将推动添加剂的额外采用,但是如果他们不提供他们承诺的东西,我们将看到市场上的一些变化。

他继续说:“我认为合并会发生,因为您有很多公司拥有良好的技术,但他们可能没有进入市场,也可能没有扩展的能力。”“最终采用添加剂的合并是健康的。”

展望未来,兰菲尔德(Langfeld雷电竞充值这些区域。他还强调了Stratasys的重要性作为创始成员的新影响力的Additive Manufacturer Green Trade Association(AMGTA)将来朝着更负责任和可持续的制造模型努力。

兰菲尔德总结说:“我认为现在有一波新的认识大型生产公司,可以真正研究它们如何在本地生产,并利用添加剂制造来库存和备用零件管理。”雷电竞充值“这些正是我们期望未来增长和可持续制造的强烈迹象的应用。”

返回(新的?)正常

The TCT 3Sixty trade show floor appeared somewhat quieter than previous years, likely due to a combination of Covid-19 uncertainties, international travel restrictions, and being sandwiched between RAPID + TCT earlier this month and Formnext in November.

尽管如此,似乎有sentim共享ent among exhibitors and visitors alike that a return to in-person events and face-to-face conversations was warmly welcomed, even if footfall was a little lower than prior editions. For many, the event provided the first in-person chance to get a real look at some of the technologies launched over the last two years.

该节目的会议方面由80多个演讲和小组会议组成,促使人们进行了各种主题的讨论,总体上关注评估,采用和优化企业的3D打印技术。

关注现在会转向formnext在11月,预计将进行大多数即将推出的发射。不过,在此之前是备受喜爱和高度期待的回归2021 3D印刷行业奖,现在对候选名单进行投票现已开放。

订阅3D Printing Industry newsletter有关增材制造中的最新消息。雷电竞充值您也可以通过关注我们来保持联系推特and liking us onFacebook.

Looking for a career in additive manufacturing? Visit3D打印作业在行业中选择一系列角色。

Subscribe to ourYouTube channel有关最新的3D打印视频短裤,评论和网络研讨会重播。雷竞技在线登录

特色图片显示新的Revo Six(左),Revo Micro(右)和四个Revo喷嘴。迈克尔·皮奇(Michael Petch)/3D印刷行业的照片。