Three newLubrizolESTANE 3D thermoplastic polyurethane (TPU) materials for fused filament fabrication (FFF) 3D printing are now available on theUltimaker市场。

Lubrizol’s ESTANE 3D TPU F94A-055 OR HH PL, 3DP TPU 98A, and 3DP TPU F70D thermoplastics have been added to the free digital platform. The filaments are designed to address Ultimaker customers’ demands for plastics that can be used in FFF applications for industrial jigs and fixtures, prototypes, end-use parts, and flexible parts such as orthopaedic insoles.

“Lubrizol’s grades open the door for a great deal of possibilities for end-users printing with TPU; varying from outdoor parts with cold flexibility, to parts that require long-term heat performance.” said Bart van As, Materials Product Manager at Ultimaker. “Filaments made from Lubrizol’s ESTANE 3D TPU are among the softest and most flexible materials that can be printed on Ultimaker 3D printers.”

Ultimaker的3D打印市场

荷兰3D打印机制造商Ultimaker通过Ultimaker Cura应用这使原材料供应商可以上传与Ultimaker打印机兼容的配置文件。该公司称,其屡获殊荣的开源软件每月拥有超过500,000个唯一用户,每周有140万个印刷作业。

在线申请是launched at TCT 2017to support the increased adoption of its 3D printers by professional designers, engineers, researchers, and manufacturers. Since then, the service has been enhanced by the additions of other material manufacturers such asEssentium,eSUNandPolymaker,加入公司的物质联盟计划在2019年。

Following the incorporation of Lubrizol’s TPU grade resins, the platform now supports 157 3D printing materials for a wide range of applications, which allows customers to avoid manual setup when using third-party materials.

Lubrizol’s advances in 3D printing

Lubrizol是一家位于俄亥俄州的化学和材料公司,在世界各地设有100多家制造设施和办公室,并拥有约8,800名员工。自1928年成立以来,该公司已成为运输,工业和消费市场的专业化学品提供商,其产品包括添加剂,例如发动机油,工业润滑剂,汽油和柴油。

近年来,Lubrizol试图使其材料更容易在3D打印市场中获得,并且该公司加入了生命值’s Open Materials platformin 2017. Under the agreement, Lubrizol is not only able to access HP’s Open Materials and Applications Lab and its research tools, but it can develop materials under the HP brand.

该公司继续在3D印刷行业中晋升announcing a partnershipwith Chinese 3D printer manufacturerFarsoon Technologiesat2019年的FormNext。该协议使Lubrizol扩大了其TPU粉末的影响力。

Lubrizol’s ESTANE 3D TPU M95A powderpassed skin sensitization and cytotoxicity testsin April 2020. The successful testing of the materials, which were produced using HP Multi Jet Fusion (MJF) technology, meant they could be used to 3D print products for end-use applications requiring contact with skin, such as footwear, prosthetic devices, and wearables.

TPU树脂的埃斯坦范围

In 2018, the company推出了它first three 3D printing materials在埃斯坦印记下:埃斯坦ETE(易于伸出)TPU,埃斯坦58000 TPU和埃斯坦MVT(水分蒸气传输)TPU。这些柔软的,柔软的,坚硬的和刚性的3D可打印材料,然后在当年晚些时候推出了Estane TRX TPU和Bouncell-X,它们是为鞋类市场设计。

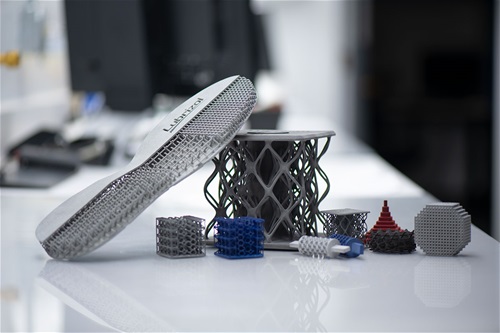

The company’s ESTANE range has been engineered to meet high-performance demands across a variety of applications from footwear to consumer and industrial products. Its portfolio of TPU resins provide 3D designers with polymers that enable thin part walls, enhanced layer-to-layer adhesion and consistent 3D printing of soft and flexible materials.

现在,Lubrizol的三种最新的Estane 3D打印材料已添加到Ultimaker的数字平台中。据报道,3D TPU F94A-055或HH PL丝具有高热的长期稳定性,而3DP TPU F70D对于由于其灵活性和良好的全方位机械性能而容易进行粗糙处理的零件很有用。另一方面,3DP TPU 98A提供了增强的磨损和耐化学性,抗击力和挤压量始终如一地使其易于打印。

“We’re very committed to making TPU materials with easy to process and consistent properties available via the Ultimaker Material Alliance Program, to provide long-term and sustainable solutions to all the end-users,” saidDavid Pascual, Lubrizol’s Global 3DP Marketing Manager. “By focusing on differentiation, our goal is to attract new applications and help increase adoption of Ultimaker 3D printers.”

Recently released FFF 3D printing materials

FFF is one of the most widely-used techniques in 3D printing, and new thermoplastics are continually launched with the aim of creating products with enhanced features.

German specialty chemicals companyEvonik引入了它Vestakeep i4 3DF2020年5月,植入物级的聚醚乙醚酮(PEEK)丝。新材料允许使用FFF 3D打印生产3D塑料手术植入物。

Polish 3D printing filament manufacturerSpectrum Filaments推出了它ABS医疗和PETG FX120材料在2020年4月。旨在用于医学和工程应用中,灵活的树脂显示出高温阻力。

EssentiumInc., the Texas-based 3D printer manufacturer,announced a partnership与化学专家Lehvoss Groupto develop high-performance materials for additive manufacturing in March 2020. The deal will see a line of PEEK and High-Temperature Nylon (HTN) filaments created specifically for production-level extrusion-based 3D printing processes.

您现在可以提名2020 3D Printing Industry Awards。Cast your vote to help decide this year’s winners.

要了解最新的3D印刷新闻,请不要忘记订阅3D Printing Industry newsletteror follow us on推特or liking our page onFacebook。

Looking for a job in the additive manufacturing industry? Visit3D Printing Jobsfor a selection of roles in the industry.

Featured image shows a range of products that can be 3D printed using Lubrizol’s ESTANE filaments. Photo via Lubrizol.