提名2021 3D印刷业奖are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

研究人员在University of Baselhave developed a novel 3D printed implant for treating eye socket fractures that carries a reduced risk of patient rejection.

使用A构建Prusa i33 d printer and PEEK filament, the team’s grafts are able to overcome the bioinertness of their material thanks to their porous features, which can be tailored to enhance cellular repair. Through Finite Element (FE) analysis, the team have also found their devices to be highly-customizable, meaning that in future, they could be adapted to meet the needs of individual optical patients.

“The printing of high-temperature, implantable-grade thermoplastic polymers such as PEEK, paves the way for a more sophisticated generation of biomaterials,” said the team in their paper. “Implementing FDM [3D printing] at point-of-care offers less material wastage, easy operator training, faster implant production, increased cost-effectiveness and patient specificity.”

治疗“轨道地板骨折”

当涉及面部伤口时,所谓的“轨道地板骨折”代表了最具令人毛骨悚然的伤害之一。通过钝力击中面部的常见副作用,轨道地板骨折有效地看到受影响的患者眼中的墙壁受损,并且尤其难以鉴于现场的模糊地点。

虽然虚拟手术规划(VSP)的进步继续使这种眼部插座骨折比以往任何时候都更容易,但相关的外科材料仍然是最佳患者结果的障碍。同时,PEEK是一种强大的3D印刷聚合物,其右侧,并在这方面显示了相当大的潜力,但根据瑞士队的缺乏生物活性是“临床关注”的原因。

In the past, researchers have toyed with the idea of coating PEEK to improve its osseointegration, but poor binding can lead to the material’s degradation and ultimately osteolysis. Alternatively, given the technology’s inherent design flexibility, 3D printing is increasingly finding surgical graft applications, in which it allows for the realization of porous implants that foster greater cell regrowth.

However, despite the clinical potential of additive manufactured medical devices, the Basel researchers found no existing studies that examine the behaviors of PEEK FDM 3D printed implants, thus they’ve now established a workflow which enables the production of customized grafts, that feature improved surgical applicability.

努力偷看性能

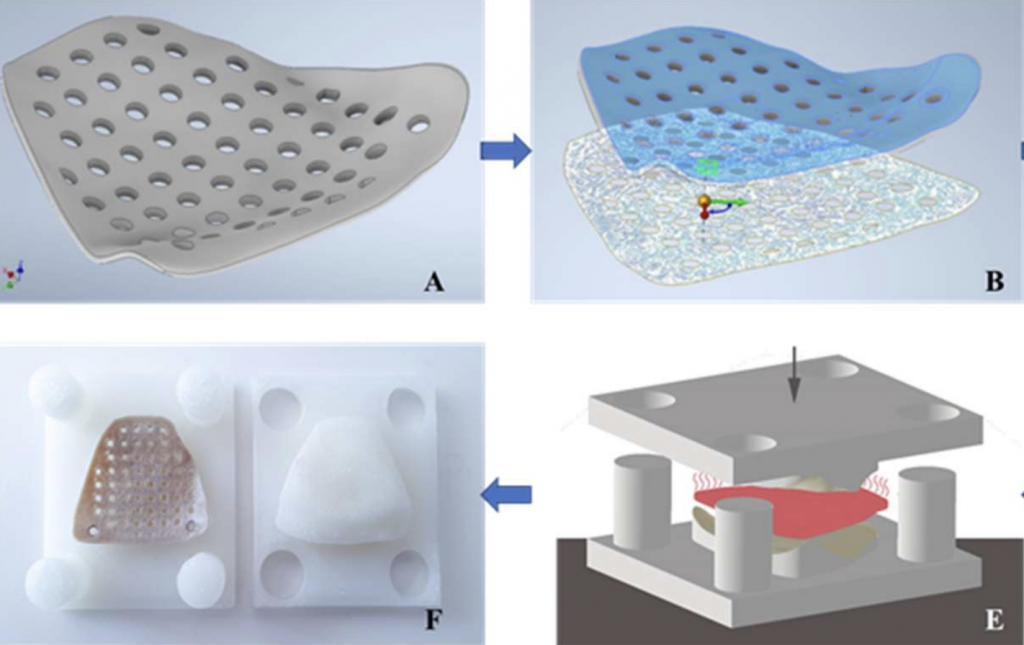

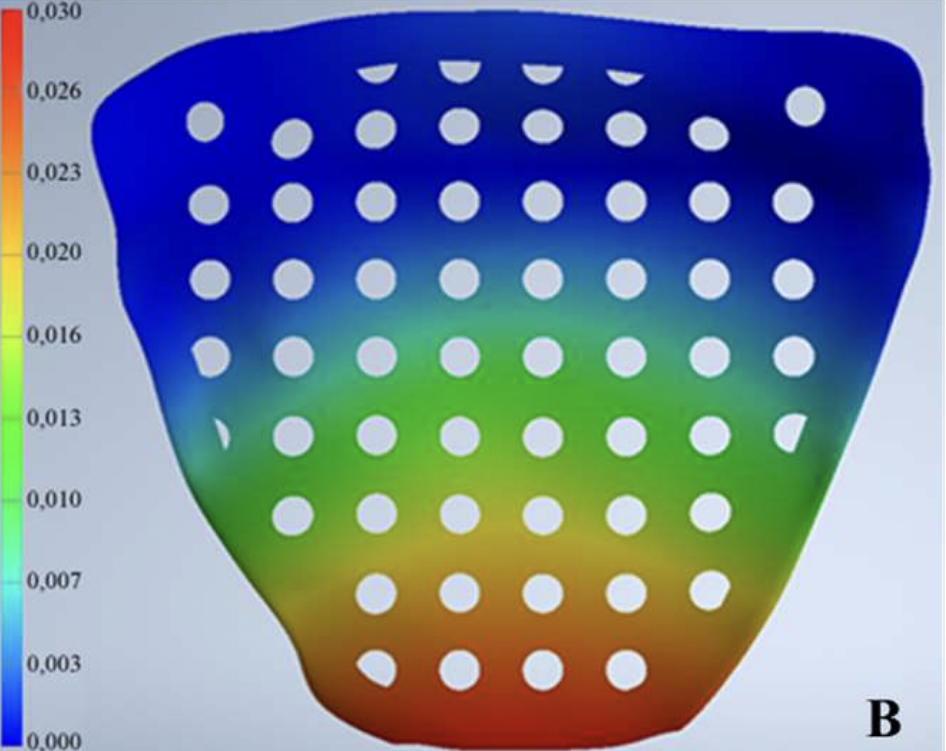

首先,团队创建的服务器的有限元模型al different orbital mesh implant designs, and used simulation software to test their performance against clinical ‘worst case scenarios.’ Based on their findings, the researchers opted to integrate 1.5 mm screw points into each of their devices’ ‘rims’ as a means of holding them in place during end-use, before exporting them as STL files for printing.

有趣的是,团队的初步模型因其复杂的悬垂而失败,强迫研究人员采用“反向折纸”方法。在实践中,这意味着使用“未包装”功能在2D中将其3D植入物数字转换为2DAutodesk的发明家程序,在挤出它们之前,手动从印刷床上移除它们。

In order to make their grafts 3D again, the researchers then used a mold and press box to heat and compress them back into their desired form, before grading and analyzing their qualities. Each device was marked based on their deformation under 0.3N as well as their morphological fit, and unsurprisingly, results showed that the thinnest implants also exhibited the highest levels of stress under pressure.

关于适应和准确性与患者模型相比,每个设备通过团队自身的规模缩小了最少的“令人满意”,而矩形植入物被标记为最强大。因此,该团队得出结论,他们的方法与所产生的设备一样重要,而且FE型号允许他们迅速迭代患者友好的设计。

“Using Multi-criteria decision-making (MCDM) [assessments], FE-based computational analysis and FDM can be evaluated in multiple treatment options,” explained the team in their paper. “This approach demonstrates that a range of combinations can be assessed to reach the most effective clinical solution.”

3D printing’s optical potential

Given the enclosed nature of the human eye socket, it can be a very difficult area to operate on, but surgeons are increasingly finding that 3D printing and modelling can help optimize their patients’ chances. Earlier this year, for instance, doctors at the IsraeliGalilee Medical Center(GMC)combined 3D printing with VR, to develop a novel way of treating optical fractures.

在过去,研究人员波尔图大学以类似的方式部署了添加剂制造雷电竞充值help reconstruct the eye47岁的女人。使用Institute of Science and Innovation in Mechanical and Industrial Engineering,该团队能够创造高质量的假肢,同时降低其相关的交货时间和成本。

Elsewhere, at the BrazilianPaulista University, scientists have developed a means of capturing and3D printing facial prostheticsfor those living with maxillofacial defects. Based on smartphone-captured scans, the team have already been able to create prostheses for a cancer survivor who lost her right eye and part of her jaw.

The researchers’ findings are detailed in their paper titled “A multi-criteria assessment strategy for 3D printed porous Polyetheretherketone (PEEK) patient-specific implants for orbital wall reconstruction.”

The study was co-authored by Neha Sharma, Dennis Welker, Soheila Aghlmandi, Michaela Maintz, Hans-Florian Zeilhofer, Philipp Honigmann, Thomas Seifert and Florian M. Thieringer.

提名2021 3D印刷业奖are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

要及时了解最新的3D印刷新闻,请不要忘记订阅3D Printing Industry newsletteror follow us on推特or liking our page onFacebook.

对于深入潜入的添加剂制造,您现在可以订阅我们的雷电竞充值YouTubechannel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit3D Printing Jobsfor a selection of roles in the industry.

Featured image shows the researchers’ 3D printed eye socket implant installed on a skull model. Photo via the University of Basel.