研究人员University of Manchester在英国,首次证明了使用2D材料MXENE的3D打印独立物体的可能性。作为第一个关于MXENE的3D可打印性的研究,该团队已经开发了用于挤出材料的水性墨水。通过实验显示高电容和能量密度的MXENE电极3D打印。电极可用于储能设备,例如超级电容器。

3D structures from 2D materials

2D材料也称为单层材料。当晶体变细至一个原子厚,独特的物理和化学特性时。世界上第一个2D材料是石墨烯,在曼彻斯特大学发现。虽然比人的头发柔性,透明和百万倍,但石墨烯也比铜的传导性更高,并且比钢强得多。

自2004年独立以来,石墨烯打开了门for the exploration of other 2D materials. In 2011, MXenes, a class of ‘clay-like’ 2D materials composed of early transition metals (such as titanium) and carbon atom are first developed. Compared to graphene, MXenes have excellent electrical conductivity, hydrophilicity and high density.

为了利用这种理想的特性,科学家需要有效地将2D材料整合到3D结构和设备中。但是,使用常规技术很难实现所需的复杂的3D体系结构。

3D printing solves this problem while providing a high degree of architectural control, scalability and cost-effectiveness. Attempts at3D printing graphenehave been developed and applied tosupercapacitor和rechargeable battery发展。采用类似的路线,对团队的剩余挑战是使具有单一至几层mxene的墨水具有3D打印所需的流变特性。

3D打印与MXENE

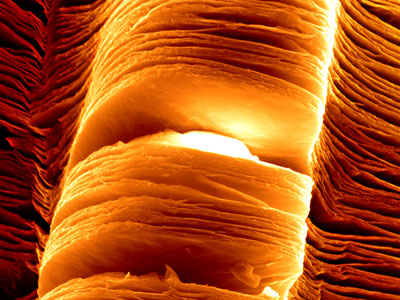

在曼彻斯特大学的研究中,将几个原子厚的大mxene片(平均侧向尺寸为8 µm,厚度为1 - 3 nm)溶解在水中,以制成3D打印墨水。作为亲水性使MXENE非常容易地分散在水性悬浮液中,非常适合形成水墨。研究人员采用了基于挤出的3D打印,选择了研究最多的MXENE材料,即2D TI3C2TX的理想粘弹性特性。

“The inks we developed provide a good translation of properties from the 2D material into 3D, resulting in architectures with significantly improved specific surface area compared to other approaches,” said Dr Suelen Barg,lecturer in structural materials at the University of Manchester。

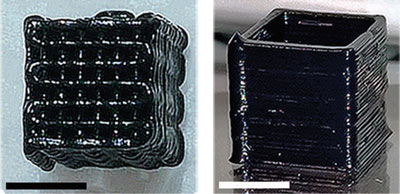

用微米大小的喷嘴打印3D打印后,将湿3D结构冷冻干燥。冷冻干燥可保护内部完整性和较低收缩的结构的外部形状。该技术能够制造20多层高的MXENE架构,具有明确的形状和高特异性的表面积。没有添加剂或任何进一步的热或化学处理,实验中直接印刷了微小的矩形棱镜和空心矩形棱镜。

Due to the excellent electrical conductivity of MXene, its potential to manufacture energy storage devices such as supercapacitors is of particular research interest. Supercapacitors can produce massive amounts of power while using much less energy than conventional devices. In the experiment, an interdigitated symmetric supercapacitor with a solid electrolyte was 3D printed with MXene. Both the electrode and current collector are 3D printed, thus eliminating the need to employ noble metals to be used as current collector in the electrode designs.

The 3D printed electrodes, with an active material loading of about 8.5 mg cm-2, exhibit a high areal capacitance of 2.1 F cm^-2, at 1.7mA cm^-2 and gravimetric capacitance of 242.5 Fg-1 at 0.2A g-1 with a retention of above 90% capacitance for 10000 cycles. They also achieve a high energy density of 0.0244 mWh cm-2 and a power density of 0.64 mWcm-2 at 4.3 mA cm-2.

“These results are among the highest in the literature and confirm that our synthesis and processing route allows an excellent translation of properties from the 2D material to the assembled 3D device,” pointed out Wenji Yang, the first author of the paper.

Applications of MXene devices

Potential uses for these MXene devices are for the automotive industry, such as in electric cars as well as for mobile phones and other electronics. In particular, 3D printed MXene architectures are particularly attractive for energy storage applications such as rechargeable lithium- and sodium-ion batteries, lithium-sulfur batteries and supercapacitors. They could also be used in other applications such as energy conversion, photocatalytic fuel production or electromagnetic shielding.

“The unique rheological properties combined with the sustainability of the approach open many opportunities to explore,” said Dr Suelen Barg, the supervisor of the research team. The group’s current research direction is optimizing their MXene ink formulations and additive manufacturing protocol to fabricate bespoke energy storage devices in asymmetric configurations. With the goal of overcoming the voltage window limitations and further enhancing the energy density, the team is also working on incorporating multi-materials printing and alternative electrolytes.

3D打印of Freestanding MXene Architectures for Current‐Collector‐Free Supercapacitorsdiscussed in this article is published online in Advanced Materials. It is co-authored by Wenji Yang, Jie Yang, Jae Jong Byun, Francis P. Moissinac, Jiaqi Xu, Sarah J. Haigh, Marco Domingos, Mark A. Bissett, Robert A. W. Dryfe, Suelen Barg.

For more of the latest research news subscribe to the3D打印Industry newsletter, 跟着我们Twitter和like us onFacebook。在学术界寻找工作?启用您的个人资料3D打印Jobs, or广告to find experts in your area.