Netherlands-based metal 3D printer manufacturerAdditive Industrieshas revealed how it plans to drive ‘productivity leadership’ across the industry ahead of this year’sformnexttrade show.

According to the firm’s CEO Ian Howe, “driving down the cost per kilo” of printed parts, is the “biggest challenge facing the industry.” To get around this, Howe says that the company aims to increase the machines’ productivity by at least 30% every year, and speaking exclusively with 3D Printing Industry, he has now revealed its plans to launch the high-throughput ‘MetalFAB G2’ at Formnext next month.

“The industry has been working in ‘niches’ for the last twenty years,” explained Howe. “To really drive the penetration of 3D printing into full industrial-scale applications, we need to continuously reduce manufacturers’ cost per kilo every year, and drive what we call productivity leadership.”

“If you look at the G2, it is a largely-upgraded platform, which delivers a major step forward in productivity compared to just two or three years ago,” added Howe. “We’re planning to have ‘core,’ ‘continuous production’ and ‘automation’ offerings, each of which will deliver massively-improved productivity leadership and cost per kilogram to customers.”

A modular metal AM approach

Additive Industries was formed on the back of a wave of metal 3D printing advances during 2012, in the city of Eindhoven, which has fast become a hub for like-minded tech firms. With close local access to supply chains, mechatronics, and optical expertise, the company was soon able to launch its first system: theMetalFAB1in 2016, a machine that continues to bring benefits to its customers in aerospace, automotive, industrial, energy, and high-tech market verticals.

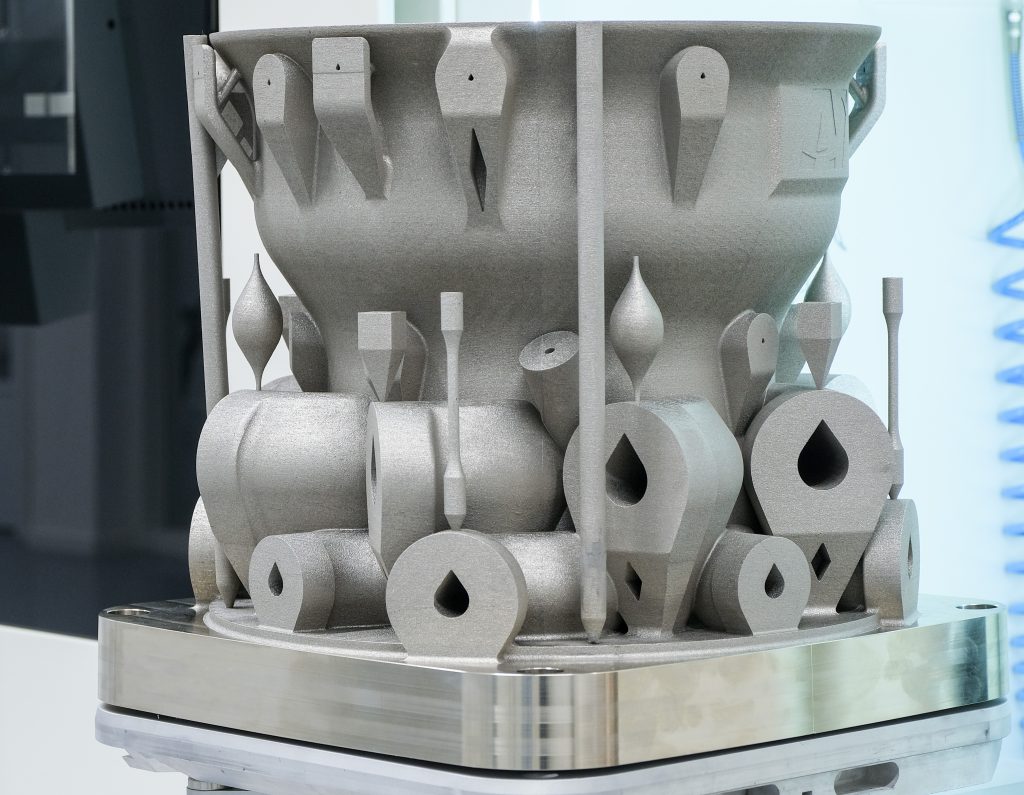

Designed to manufacture components at an industrial scale, Additive Industries’ first 3D printer is uniquely modular, and it can be chained into configurations up to eleven systems long if desired. This, in combination with its automated processing capabilities, allows the machine to achieve higher part throughputs than comparable 3D printers and enables users to scale their production to meet client demand.

“From the beginning, our focus was on making a powder bed fusion (PBF) technology that’s capable of competing with traditional component manufacturing technologies such as casting, forging, and machining.”

One of the first adopters of the MetalFAB1 was Scalmalloy producerAPWORKS, which has since continued its work with Additive industries, with the aim ofqualifying printed aerospace partsfor serial production. In the world of Formula 1, the system’s rapid throughput has also made it ideal for meeting theAlfa Romeo Racing ORLENteam’s lightweighting needs, and its car featured143 3D printed partslast year.

Over the last five years, Howe says that Additive Industries has now developed its platform to the point that it delivers “stable, high-quality, industrial-ready” parts, but to really take things to the next level and become “the driving force behind large-frame metal manufacturing,” it needs to start “bringing the largest possible gains to OEMs.”

What is ‘productivity leadership?’

When it comes to making metal 3D printing a viable alternative to traditional large-scale manufacturing, Howe says that both modularity, and reducing the number of human-powder interactions during production, are critical to success. However, Additive Industries’ CEO also emphasizes that balancing part quality against optimizing throughput, is a battle that his company fights “every day of every week.”

“It’s always a trade-off between productivity and quality,” explains Howe. “Yes, we can drive productivity with more high-powered lasers, but in the end, you need to ensure the quality of parts as well. We continue to optimize laser power, build volume, and gas flow configurations, just to make sure we always deliver quality.”

Having successfully optimized the setup of its machines in this way, Howe believes that Additive Industries now has the productivity leadership needed to bring the benefits of 3D printing to further clients in the automotive, aerospace, industrial, and energy sectors, and expand the market greatly in areas where he sees “big opportunities” for the firm.

In fact, by partnering with the firm’s customers and jointly prioritizing further application development, Howe can see the company’s technologies addressing market demand beyond the €4 billion per year metal 3D printing sector, and accessing the wider €100 billion high-value metal market.

“As we push for productivity leadership and drive down costs, the envelope is opening and so is the basket of applications that are becoming economically feasible,” added Howe. “Price points have to be met, but by following our innovation roadmap, we see that we can help customers double their productivity every two to three years, so that’s our plan.”

formnextand the MetalFAB G2

Additive Industries’ biggest news at Formnext 2021 is expected to be the launch of the MetalFAB G2 system. Designed to deliver ‘best in class’ productivity leadership, the machine is set to be marketed in three main configurations: core, automation, and continuous production.

Alongside its new system, Additive Industries also intends to announce innovations that improve both the accessibility of its machines and users’ quality assurance capabilities during operation. To help customers deliver more consistent parts, the firm is set to unveil a multi-beam qualification tool, which according to Howe, represents a “big step forwards” in multi-laser system quality assurance.

Additionally, the company plans to reveal the integration of a beta version ofSigma Labs’PrintRite3Doffering into the MetalFAB, as well as the launch of the latest build processor it has developed in partnership withMaterialise, and Additive Studios, a new additive manufacturing consultancy services and training program.

最后但并非最不重要的一点是,该公司的FormNext展示柜也将包括有关其技术最新关键应用程序的更新。特别是,豪说,该公司已与日本加工公司合作取得了进步Makino, with which it has created an end-to-end process chain for scaling metal 3D printing.

“We have very ambitious plans for growth,” concluded Howe. “Our vision is to be the driving force in large-frame metal additive manufacturing, and working with our partners to provide the best, biggest and fastest solutions possible.”

那些有兴趣发现有关该公司技术的更多信息的人,可以从11月16日至2021年11月19日在formnext上找到其专家团队。Additive Industries’ product page.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D Printing Industry newsletteror follow us onTwitteror liking our page onFacebook.

For a deeper dive into additive manufacturing, you can now subscribe to ourYoutubechannel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit3D Printing Jobsfor a selection of roles in the industry.

Featured image shows Additive Industries CEO Ian Howe and the MetalFAB1 3D printer. Photo via Additive Industries.