Automotive manufacturer宝马strategic investment armBMW i Ventureshas provided seed funding to elastomer 3D printing start-up快速液体印刷(RLP).

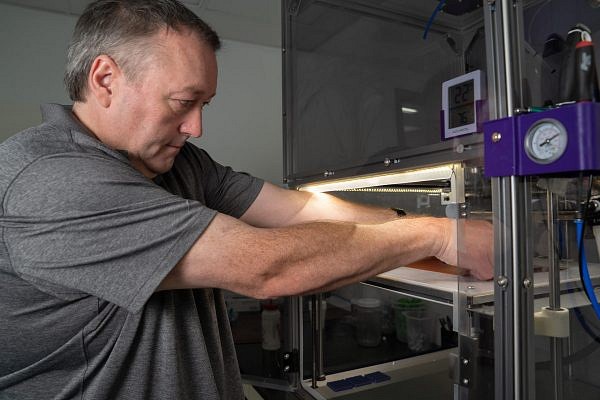

专门从MIT’s Self-Assembly Lab, the firm’s gel-dispensing technology is said to enable the production of soft, pliable products using industry-standard materials like foams, rubbers and silicones. Also backed byMassMutualthrough its MM Catalyst Fund (MMCF), RLP’s funding round is now expected to allow for both the expansion and wider marketing of its product portfolio.

“RLP’s breakthrough technology is disrupting the 3D printing space by enabling the rapid printing of elastomeric structures of any size and complexity,” said Marcus Behrendt, CEO of BMW i Ventures. “With BMW i Ventures’ support, the RLP team can continue demonstrating its commitment to creating high quality, low-cost elastomer products.”

什么是快速液体打印?

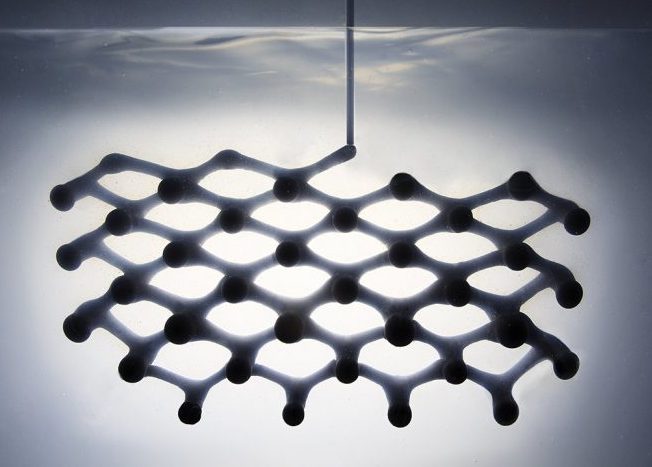

在迈阿密设计上首次亮相as long ago as 2017, RLP is essentially a printing process in which a liquid object can be ‘drawn’ within a gel suspension. Given that such prints are cured during production, they don’t require the use of supports and need minimal post-processing before use, while the technology’s scalability is said to allow for the creation of large-format parts at extremely high throughputs.

According to the RLP, its approach is superior to conventional elastomeric 3D printing technologies, as it’s not restricted by the speed, build volume or material deficiencies that make them “unreliable as mainstream manufacturing processes,” thus the firm sees it as a “game-changer” when it comes to rapidly printing “airtight, high-quality products.”

最初开发后,该技术是专门用于室内设计应用程序,但RLP现在表示已开始与“世界各地的行业领先公司”合作,以确定新的机会。为此,该公司的目标是通过其独特的流程进入医疗,鞋类,航空和汽车行业,其新资金可以帮助您实现这些计划。

RLP首席执行官Schendy Kernizan说:“我们已经花了多年的时间来完善我们的技术,并建立了解决3D印刷行业所面临的痛苦点的产品。”“通过宝马I Ventures和MM Catalyst基金的这一资金,我们将加速我们为更广阔市场提供各种解决方案的能力。”

“RLP removes limits on design, can print large-scale and multiple objects at once, and is faster than any other solution currently on the market.”

RLP: now geared for success?

While the amount of funding invested in Rapid Liquid Print hasn’t been publicized, Mass Mutual says that its $50 million CCMF fund will be used to make investments of $250,000-$2 million, so its contribution is unlikely to exceed this value.

Likewise, BMW i Ventures hasn’t revealed the value of its investment either, but the firm did announce the creation of a new $300 million pot earlier this year, and it has a long history of backing 3D printing’s innovators. Back in 2017, for example, the venture capitalist provided funding toDesktop Metal, a business that has since gone on toconduct a $2.5 billion mergerandbuy its biggest rival ExOne。

When it comes to its RLP backing, BMW i Ventures says it is impressed with the potential of gel-dispensing technology to replace injection molding in “the manufacture of identical parts in large volumes.” In fact, using Rapid Liquid Printing, the firm anticipates it being possible to slash the lead times of complex molds from 8 weeks down to a matter of minutes, while lifting molding’s “design restrictions.”

BMW i Ventures also believes that RLP’s technology enables the production of parts that currently need to be built from interlocking pieces in a single run, dramatically reducing the costs of setting up a mold. As a result, the firm sees its investment as a way of “disrupting elastomeric 3D printing” and “breaking the limits of innovation” within the industry.

“MMCF快速吸引液体打印独特的侦探hnology, highly adaptable production process and impressive leadership team,” said Liz Roberts, Head of Impact Investing at MassMutual. “We’re excited to support RLP alongside BMW i Ventures as RLP revolutionizes the 3D printing process and continues to grow and bring its innovative capabilities to new customers.”

Encouraging elastomeric innovation

由于他们独特的力量婚姻和休息时的高伸长率,弹性体继续代表了3D印刷稳健饱满的零件的有前途的途径。就在上个月,材料开发人员Chromatic 3D Materialsraised more than $5 milliontowards the development of a novel industrial-grade elastomer-based manufacturing technology.

On the post-processing front,雷电竞充值增材制造技术(AMT)也收到了Innovate UKgrant earlier this year to develop a new用于治疗弹性体的有机溶剂。当时,该公司致力于利用这笔资金来快速进行下一代化学的研发,从而改善了3D打印后处理的可持续性。

Elsewhere, in more experimental research, a team at theUniversity of California at Santa Barbara已经形成了人类组织状3D printable ‘bottlebrush’ elastomer。Having created a super-soft material with shape-holding properties for another project, the researchers found that they could 3D print it into inks, before returning the elastomer to its solid form via the application of UV light.

要了解最新的3D印刷新闻,请不要忘记订阅3D打印行业通讯or follow us on推特or liking our page onFacebook。

为了深入研究添加剂制造,您现在可以订阅我们的雷电竞充值Youtube频道,包括讨论,汇报和3D打印进程的镜头。

您是否正在寻找添加剂制造业的工作?雷电竞充值访问3D打印作业在行业中选择一系列角色。

Featured image shows a material being dispensed into a gel bath during Rapid Liquid Printing. Image via BMW i Ventures.