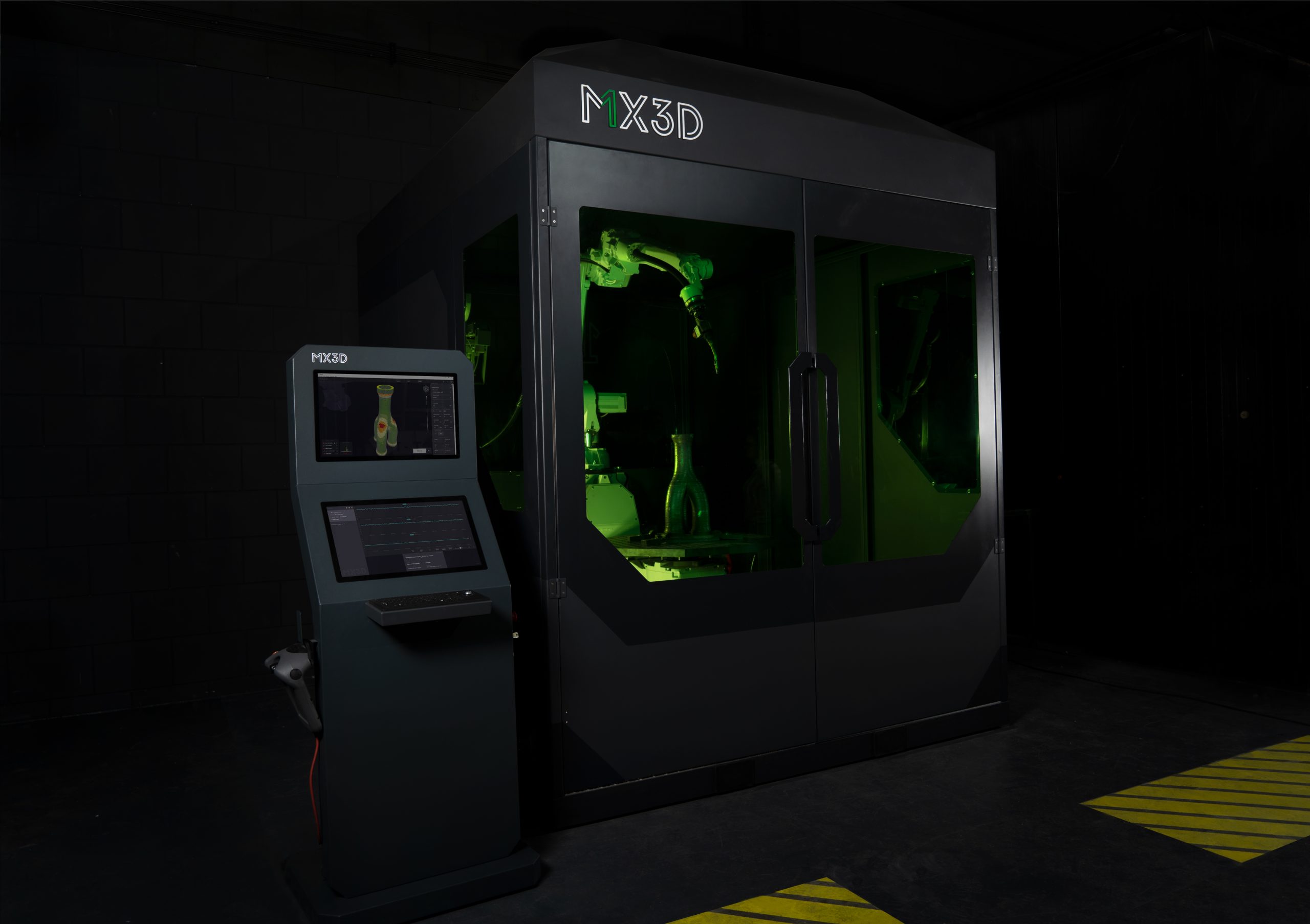

位于阿姆斯特丹的机器人金属3D打印公司MX3Dhas raised €2.25 million in an investment round that will see the company launch its M1 robotic metal additive manufacturing system.

Comprising a welding robot and MX3D’s MetalXL software and control system, the M1 can be used to 3D print metal parts for high impact industries such as oil and gas, maritime, and tooling.

总部位于荷兰的影响投资者参与者,投资基金KplusV和Startgreen Capital,PDENH,和荷兰企业机构(RVO)都为这项投资做出了贡献。除了加油M1的推出外,资金还将加快MetalXL系统的开发并支持其商业推出。

“我们的软件和控制系统使金属XLcompanies to turn their welding robot into a high end 3D metal printer, in the course of one day,” said Gijs van der Velden, MX3D’s CEO. “Since the launch of MetalXL we have received many customer requests whether we could supply them with a complete solution. The M1 Metal AM System is the answer to this call.

“现在,没有焊接机器人的顾客可以迅速而负担得起的大金属零件开始打印。”

MX3D和robotic 3D printing

MX3D成立于2015年,利用金属3D打印和智能机器人添加剂制造(RAM)技术来生产新的和高影响部门的零件。雷电竞充值该公司的生产过程结合了机器人臂和电弧添加剂制造(WAAM)3D打印机与其MetalXL软件结合使用,以生产大型且复杂的金属物体。雷电竞充值

The company has previously deployed its technology within the construction sector for the creation of a3D印刷不锈钢桥在阿姆斯特丹。尽管击中几个障碍over the course of the four-year project, the bridge was completed and exhibited at theDutch Design Week2018年10月在埃因霍温(Eindhoven)。这座桥是与智能技术集成使用传感器网络和数字双胞胎来实时监视桥梁的健康和使用。

在该项目的成功之后,MX3D与日本建筑,工程和建筑公司合作Takenaka,开发一个3D printed structural steel connectorusing its RAM technology.

该公司还为研究和开发目的开展了创意项目,包括3D printed mobile cafe和3D打印的自行车。使用其WAAM技术打印的第一款自行车MX3D由不锈钢制成,命名为弧自行车i,而第二个模型弧自行车II为了证明技术开发的进度,从铝上印刷。第二款模型比其前身要轻得多,并使用铝代表了该公司的第一个3D打印项目。

Development and commercialization

According to MX3D, its MetalXL software and control system turns existing welding robots into an industrial metal additive manufacturing system that enables users to manage the entire printing process from design to production in one place. Using funds from previous investments, the company has introduced MetalXL to multiple launching customers and will use the latest money to roll out the system commercially.

The system connects multiple brands of robots, power sources, and sensors, of which the company’s goal is to “connect several more robot brands, which allows us to service more than 80 percent of the worldwide robotic market,” Van der Velden said.

The company’s newly-developed M1 Metal AM System offers customers without access to a welding robot a complete metal 3D printer that allows them to start printing large metal parts in-house. Part of the €2.25 million investment will support the product’s launch and further development.

“ Doen参与者已经为MX3D提供了很长时间的支持,并且通过这项新投资,我们表明我们对新的M1 Metal AM系统和MX3D的未来充满信心。”“创新的MX3D解决方案使公司能够改善其生产方法,并大大减少运输和材料的需求。这可能对更可持续的未来产生重大的积极影响。”

订阅3D打印行业newsletter有关增材制造中的最新消息。雷电竞充值您也可以通过关注我们来保持联系Twitter和liking us onFacebook.

寻找添加剂制造业的职业?雷电竞充值访问3D Printing Jobsfor a selection of roles in the industry.

特色图片显示t他M1金属系统。通过MX3D照片。