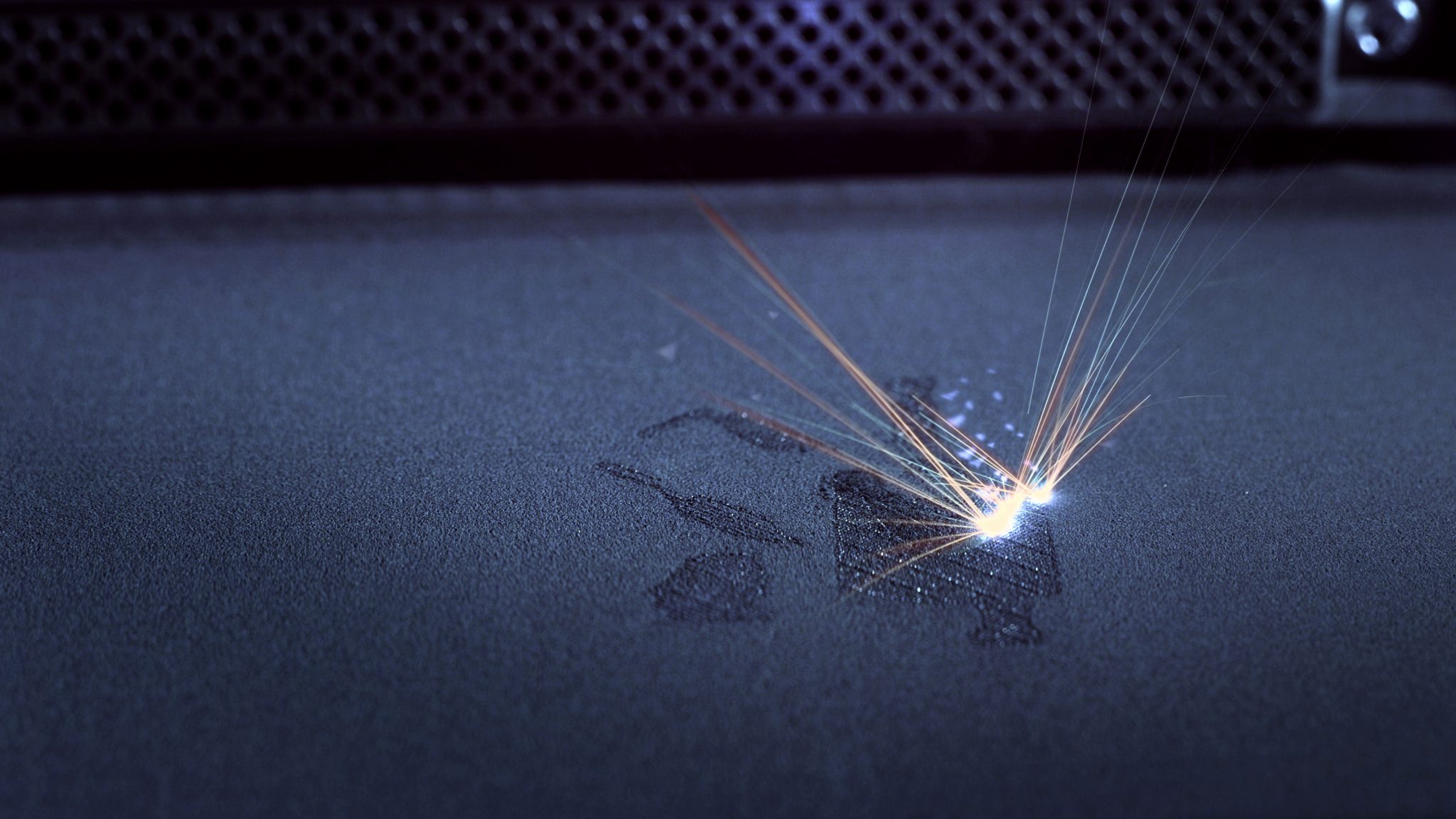

New research conducted by theEcole de Technologie Superieurein Montreal, Canada, and a separate industrial cluster, has proposed a new Additive Manufacturing Suitability (AMS) factor that can rank the printability of metal powders for laser powder bed fusion (LPBF) processes.

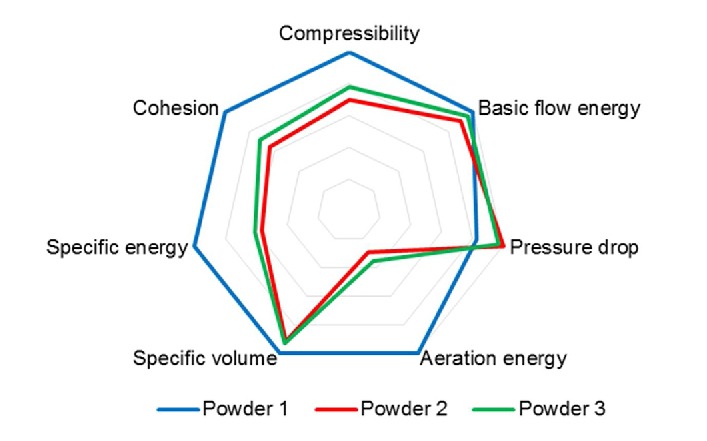

Both sets of research leveraged the FT4 Powder Rheometer from micromeritics firmFreeman Technologyto measure the dynamic, shear and bulk properties of powders and combine them into a single metric. This metric, the AMS factor, is then able to differentiate printability in a way that conventional powder testers cannot, according to the researchers.

弗里曼技术公司的运营总监杰米·克莱顿(Jamie Clayton)表示:“从粉末和机器供应商到最终用户,许多社区中的许多人都希望能够可靠地测试粉末的可打印性。

“Work such as this demonstrates progress towards this goal, emerging consensus with respect to the need to measure multiple parameters, and the value of dynamic flow properties.”

Improving LPBF 3D printing

Over the last few years, researchers and industry players alike have boosted efforts to improve andenhance the LPBF 3D printing processin order toavoid defects in metal printed parts。According to leading additive manufacturing experts, thefuture of 3D printingis likely to see increasing progress in this area going forwards.

Such attempts have involved the use ofLEDs instead of lasersto melt powder, the development of“smart” baseplates, and betterbalancing heat within the build chamberto reduce a component’s residual stress and distortion.

In September last year, scientists atTexas A&M Universityfurthered this work through the introduction of a universal method to3D print flawless metal parts via LPBF使用单向的打印数据和机器学习ing. Meanwhile, researchers atLawrence Livermore National Laboratory(LLNL) revealed their plans toexplore alternative laser beam shapes对于LPBF中通常使用的高斯梁,目的是降低金属零件的孔隙率和缺陷。

Now, the latest research in the area of LPBF printing is seeking to answer the question “Can I print with this powder?”, and aid firms and individuals in their metal powder selection.

The AMS factor

Freeman Technology’sFT4 Powder Rheometer是用于测量粉末流量和行为的通用粉末流程测试仪。FT4最初设计的旨在表征粉末和粉末流量特性的流变学,已发展为具有三个主要能力的“通用粉末流程测试仪”。

这些能力中的第一个是模拟粉末加工条件,第二个能力是应用多面粉末表征来评估动态粉末流,散装和剪切特性,第三个是使其他测试人员分类为相同的粉末的分化。。

The printability of 3D printing powders is often assessed through print trials due to the difficulty of establishing a relevant specification, however this is a time-consuming, inefficient, and costly process. To address this, researches at the Ecole de Technologie Superieure leveraged the FT4 to rank the processability of Ti-6Al-4V powders by combining the tester’s multiple measurements into a single metric, the AMS factor. The resulting AMS value was then correlated with the powder’s print performance.

According to the researchers, traditional powder testing techniques, such as flow through an orifice or tapped density methods, proved unable to provide sensitive and relevant differentiation in comparison to the AMS factor.

A second research group formed of industry partners later built on this concept. They used a modified AMS factor to successfully assess the processability of metal powders for in-situ alloying within an LPBF 3D printing process.

“We’re delighted that the FT4 can successfully rank print performance,” said Clayton. “For us powder testing is all about improving process efficiency and product performance and this is a great example of it doing just that.”

有关参考研究的更多信息,请参见题为:“粒子形态和尺寸分布对TI-6AL-4V合金的粉末流动性和激光粉末床融合的影响,”published in the Additive Manufacturing journal and co-authored by S. Brika, M. Letenneur, C. Dion, and V. Brailovski, and also in the paper titled:“粉末床融合中的原位合金:粉末形态的作用,”published in the Materials Science and Engineering journal and co-authored by M. Knieps, W. Reynolds, J. Dejaune, A. Clare, and A. Evirgen.

Subscribe to the3D Printing Industry newsletterfor the latest news in additive manufacturing. You can also stay connected by following us onTwitterand liking us onFacebook.

Looking for a career in additive manufacturing? Visit3D Printing Jobsfor a selection of roles in the industry.

Subscribe to ourYouTube channelfor the latest 3D printing video shorts, reviews and webinar replays.

特色图片显示new research establishes the concept of an ‘AM Suitability’ factor for metal powder selection. Image via Freeman Technology.