The 3D Printing Industry interviews series looking at low carbon power generation together with3D打印和可再生能源继续深入研究添加剂制造在太阳能中的应用。雷电竞充值

“3D Printing has the potential to revolutionize the solar industry,” says Daniel Clark. The entrepreneur holds multiple patents in volumetric solar energy and 3D printing and is the founder of solar energy company T3DP

我与克拉克谈到了添加剂制造业的效率是在下一代光伏技术的发展中,以及该技术解锁太阳能新时代的潜雷电竞充值力。

According toBP’smost recentStatistical Review of World Energy,太阳能在2020年记录了其有史以来最大的增长,并与风有关more than 90 percent在整个一年中,整个可再生能源领域的增长中。这种增长也反映在该行业的不断增长的市场价值中,全球太阳能市场expected to be worth $422 billionin 2022, in comparison to $86 billion in 2015.

The sun is rising on solar 3D printing

Solar remains the third-largest renewable electricity technology behind hydropower and onshore wind, with power generation increasing by a在2020年创下23%与2019年相比。

While the technology’s plus points include helping people to save money on their bills and become energy independent, there are also several caveats, such as high upfront costs, large space requirements, and the environmental impact of manufacturing the photovoltaic panels. In fact, it takes 130 liters of oil to produce a single silicon solar panel and an估计7800万公吨of toxic solar panel waste will end up in landfills by 2050.

Several years back, there was a flurry of activity within the additive manufacturing sector surrounding the 3D printing of more efficient,低成本光伏,由各种solar power innovation contests由US Department of Energy. However, there seems to have been somewhat of a tailing-off in this area since then.

不过,最近,在该领域似乎已经有活性的复兴,而薄膜材料(CTFM)实验室的化学作用似乎已经存在埃尔兰根大学在德国announcing a grantfrom the欧洲研究委员会(ERC)使用其原子层添加剂制造技术快速原型太阳能电池。雷电竞充值实验室希望在Formnext启动挑战2021获胜者, atomic layer 3D printer developerAtlant 3D纳米系统.

一家在该领域保持非常活跃的公司是加利福尼亚的初创公司T3DP, founded by Clark, which has been应用其专利的体积3D打印技术自2019年以来建造基于钙钛矿的太阳能电池板。

Nature-inspired volumetric 3D printing

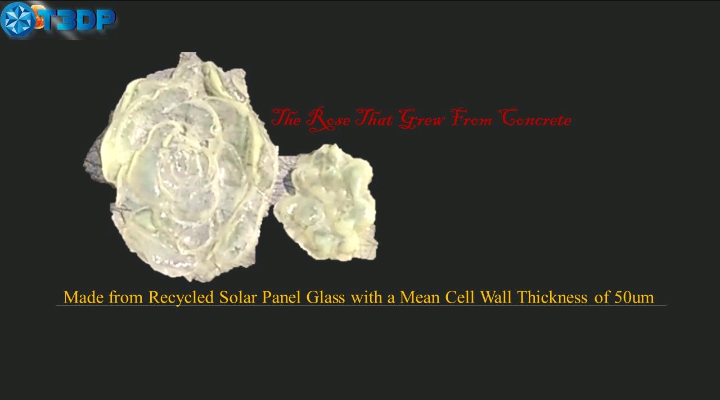

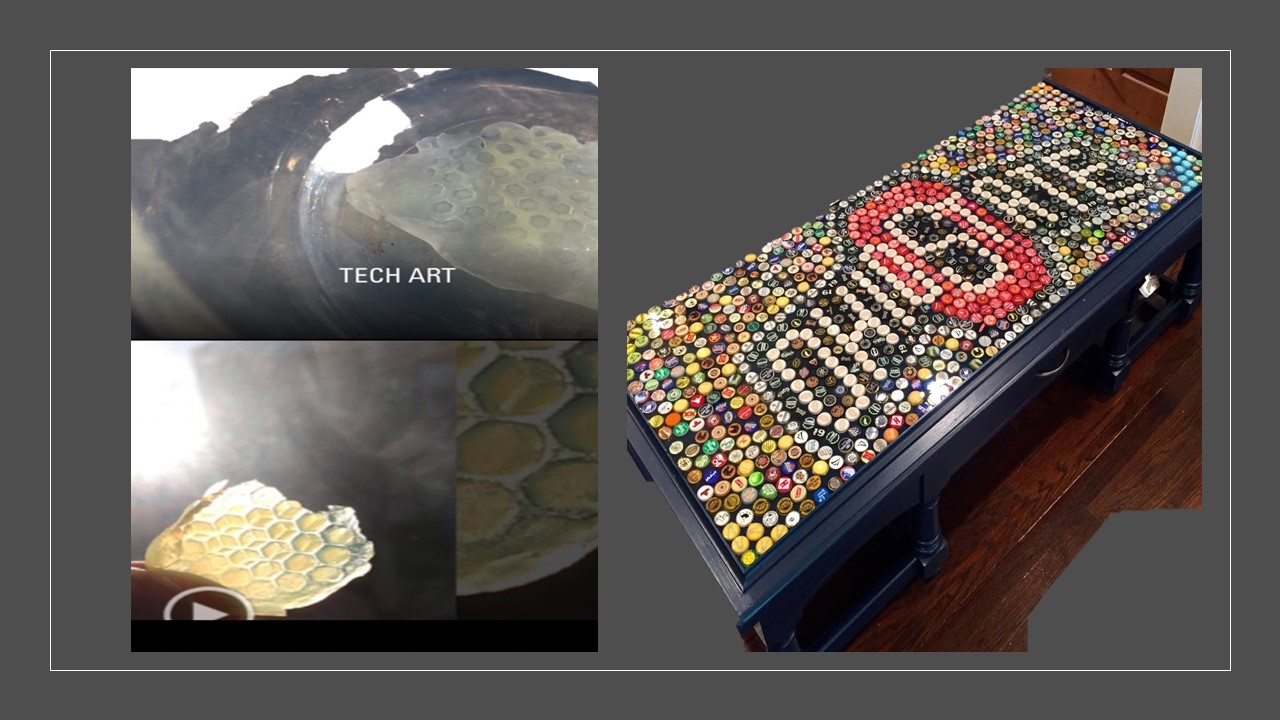

蜂窝结构的灵感insect eyes, T3DP has designed a novel solar cell able to capture three times more energy at half the cost of conventional, silicon-based cells. The process also allows micro-solar cells to be manufactured at close to carbon neutral by re-using glass from discarded solar panels.

克拉克说:“体积3D打印有可能通过增加电力输出的两到三倍的硅面板来彻底改变太阳能行业。”“典型的平板太阳能电池板每米平方200瓦,而我们的设计在同一区域可以达到400-600瓦。”

Volumetric 3D printing is a process capable of overcoming the low throughput, geometric restrictions, structural defects, and scaling concerns commonly associated with additive manufacturing by curing objects in a single step, rather than layer by layer.

Clark worked with the team of Alexander Lippert, Associate Professor of Chemistry atSouthern Methodist University(SMU), to develop and commercialize a unique volumetric 3D printer, dubbed the 3D Light PAD, designed specifically for the 3D printing of a wide range of complex components for solar cell manufacturing.

The printer operates by using a photoswitchable photoinitiator to direct polymerization to points only at the intersection of two different wavelengths of light, creating high-resolution 3D components. T3DP formed a strategic partnership with AsterTech, a company that alongside theAir Force Research Laboratory(AFRL) has developed an aerosol-jet-assisted perovskite deposition method for fabricating high-quality solar cells on the complex surfaces SMU and Clark produced using their 3D Light PAD printer.

Clark’s volumetric 3D printing patent was granted last year after a four-year application process, with the IP now being utilized by volumetric 3D printing start-upxolo.

While there are no real-world application scenarios that Clark can publicly talk about right now due to a non-disclosure agreement (NDA) with xolo, he says: “While the volumetric 3D printing technology is awesome, it’s still two to three years away before we will see any major mainstream applications. However, the printer is the beachhead to my new Subzero Molding and Embossing technology that can scale the manufacturing of our micro 3D solar cell substrates from recycled solar panel glass.

“我们有一些专利的延续,其中包括Lightfield Labs的固体光线的新的真实体积显示。”

Lightfield Labsis developing next-generation holographic display technologies and has backing from the likes of multinational technology firmBosch克拉克说,这将对Lightpad 3D打印机及其未决专利产生兴趣。

Scaling solar with next-gen advanced manufacturing

Clark’s Sub Zero Manufacturing technology is designed for the mass production of flexible optically smooth solar cell substrates from recycled solar panel glass which do not require post-processing or polishing. The process involves mixing the crushed recycled glass withGlassomer紫外线可愈合的树脂和Tethon 3DGenesis Development Resin and “punching” the material into a 3D spiked pyramid shape imprinted with ultra-small micro LEDs.

The technique is reportedly “thousands of times faster” than 3D printing alone, and Clark believes the technology could also be effectively applied to the semiconductor industry to improve its green footprint.

关于太阳能产生领域的当前状态,克拉克提供了:“当前的硅太阳能部门由中国主导和控制。去年10月的7-8周,硅价格上涨了300%。随着这一趋势的上升,我看到西方世界有机会通过高级制造美观的太阳能制造,这将很难伪造。

“我预见了我们先进的一步体积3D打印和独特的Subzero成型工艺,以创建协同的二分法,以平衡返回欧盟,美国和西方世界的太阳能制造能力。”

Clark also works forVillara Energy Systems, developer of the VillaGrid energy storage system which claims to deliver more power, more safety, and more useful life than traditional home batteries. While the firm isn’t using Clark’s volumetric 3D printing technology yet, he says it is plausible that someday the process could help the mass manufacturing of batteries and solar cells at the firm’s battery and solar manufacturing facility in Sacramento County, California.

Make sure tosubscribe to our newsletter而且,不要错过该系列的下一部分,我们将研究3D打印如何帮助使氢经济更接近现实。

Looking for a career in additive manufacturing? Visit3D Printing Jobsfor a selection of roles in the industry.You can also stay connected by following us onTwitterand liking us onFacebook.

Subscribe to ourYouTube频道for the latest 3D printing video shorts, reviews and webinar replays.

特色图片显示T3DP较大太阳能电池板的六角形部分。通过T3DP图像。