We review the Elegoo Mars 3D printer.

The Mars is a consumer-grade, desktop-sized UV LCD resin printer produced by Chinese technology start-upElegoo.Priced at just $259, this printer delivers premium prints without a premium price tag. Marketed at hobbyists, the Mars is easily accessible for both long-time 3D printing enthusiasts and first-time users looking to dip their toes into the world of resin printing.

With a modest but typical printing volume of 120x68x155 mm, the Mars is limited in its output to jewellery, tabletop miniatures, pop-culture paraphernalia and small mechanical prototypes. All digital functions are controlled by a full colour 3.5” touch screen display on the front panel whereas connectivity is limited to a USB 3.0 port found on the back panel.

A 2560×1440 2K LCD screen backed by an array of 405 nm UV lights and mirrors delivers an industry-standard XY resolution of 0.047 mm. Coupled with a minimum layer height of 0.01 mm, the Mars has the capability to produce prints of much higher quality than even the more sophisticated FFF machines. The printer is supported by the well-established and reliable ChiTuBox 3D slicer.

Unboxing, Setup and First Impressions

Upon first handling the Elegoo Mars, it is evident that the Chinese manufacturer has put great effort into its design and assembly. The printer has a well built, robust aluminium body with a matte finish giving it a premium feel. Weighing in at 5 kg with 195x195x405 mm cuboid body, it feels right at home on a household desktop. The single USB port on the back panel can be difficult to reach in situations where it is up against a wall but apart from this minor inconvenience, the printer has some well thought out architecture. The Z-axis height of the printing bed is controlled by stepper motors spinning a threaded rail. The motion looks and feels stable with no hiccups.

As with all resin printers, there is a UV filtering cover over the print area. The UV cover is in place to prevent resin in the tank from curing prematurely due to external UV sources like the sun. However, it is still recommended that the printer is stored away from direct sunlight as the cover does not block 100% of the rays hitting it. In the case of the Mars, it is in the form of a cuboid lid encapsulating the space above the LCD screen. The blood-red colour of the base model ensures an impactful visual presence regardless of its surroundings. Housed in the print area under the cover is a printing bed and a resin vat. The resin vat is bounded by transparent FEP film and can be slid out from under its brackets with the loosening of two screws. The printing bed is sturdy, locked into place on the threaded rail with a single large screw and displays a centred Elegoo logo.

包括几乎所有需要在盒子里to get the user started on their first print bar a few consumables. Once a bottle of UV curable photopolymer resin and a bottle of 95%+ isopropyl alcohol have been purchased, the printer is ready to go. Elegoo’s own resin works best with the Mars but any resin curable at a wavelength of 405nm will be suitable. The isopropyl alcohol is key in post-processing for cleaning excess resin off the prints.

All the tools required to loosen and tighten the various screws around the body of the printer are included along with plenty of spare screws. The instruction manual included in the box details how to go about the assisted levelling process which takes about five minutes. It’s simple enough to be followed easily by any first-time user and once levelled, the build platform stays levelled for at least a couple of weeks of heavy use. This is enabled by the 3.5” touchscreen which is a gateway to language settings, an LCD test and Z-axis manipulation.

Slicing and Post Processing

Upon loading up ChiTuBox, the user is greeted with a refined blue and grey user interface. Once the desired 3D model is uploaded, the placement on the printing bed, the rotation of the object and the size scale can all be altered. ChiTuBox also provides mirroring and hollowing functions that are designed to save time and resin respectively.

Once the model is oriented as the user desires, it must be supported to ensure all islands are connected to the printing bed. The support functions on ChiTuBox are intuitive and easy to pick up; the add support function generates individual supports and the delete support function deletes them. For the lazier or time-conscious users, an auto-support function is available which allows the programme to automatically generate supports on every part of the model it sees fit.

We’ve found this function to go overboard however, ensuring a successful print but generating supports in areas that don’t need them. The unnecessary support scarring, in this case, makes the extra time and effort required to manually support a model more than worth it. The more conscientious users can benefit from even deeper support settings, such as support thickness, minimum support length and support angles. Once the model is adequately supported, it can be sliced and saved to a USB stick, ready for printing.

Once the print is complete, signalled by a helpful beep, it must be scraped off the printing bed with the tools provided in the box. At this stage, the excess resin must be cleaned off in a bath of 95%+ isopropyl alcohol for five minutes. An ultrasonic cleaner will be helpful but is not essential. The dried print must then be cured under UV light for another 5 – 10 minutes. Again, a UV station will be helpful but is not essential; direct sunlight is more than adequate.

Benchmarking the Elegoo Mars

After meticulous testing by our in-house engineers, several benchmarks have defined the capabilities of the Elegoo Mars. These include an Elegoo test rook, a classic Benchy, a repeatability test, an overhang test, a bridge test and a small, precise parts test. Real application tests were also performed where some popular models were printed to give an idea of how the Mars would fare in the hands of a typical consumer.

First up, the Elegoo test rook. Elegoo provides this file as standard with every purchase of the Mars. The rook is made up of sharp edges, smooth curves and even has some script pasted on it. It’s a jack-of-all-trades benchmarking file much like the classic Benchy. The Mars did an amazing job of printing the fine details on both the rook and Benchy. The organic shapes are smooth, the sharp corners are crisp, and the wording is easily legible.

Next, the repeatability test was performed whereby the printer’s ability to recreate shapes precisely was tested. The test is composed of three different structures which are all printed five times – a tube, a square with a hole and a hexagon with a pill-shaped crevasse. In each of these prints, a mean of difference of under 0.3 mm between the printed objects and the reference files was desirable. The Elegoo Mars handled this test beautifully with every parameter at or under the 0.3 mm threshold. The tubes scraped in at 0.3 mm whereas the squares and hexagons were comfortably within the range at 0.034 mm and 0.026 mm respectively. This is proof of the Mars’ ability to print mechanical prototypes with tight tolerances numerous times without significant deviation from the source.

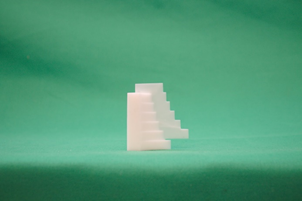

The next test performed was the overhang test which determines the sharpest angle the printer can print at without supports. The model is comprised of six overhanging lips that depart at increasingly steep angles, from 40 degrees to 65 degrees with 5-degree intervals. It was concluded that overhangs up to 55 degrees were printed without significant deformation meaning the maximum overhang angle the Mars can handle is 55 degrees. Angles sharper than this limit did not maintain their straight profiles and had visibly curved due to being unable to hold their own weight.

The penultimate benchmarking test before real applications was the bridge test. The bridge test is designed to determine how well a printer handles horizontal structures with no supports. The bridges increased in length from 25 mm to 60 mm. It was refreshing to see the Mars print all the bridges successfully even though all bridges after 25 mm visibly deformed as resin printers tend to perform poorly in this category. The structurally sound 25 mm print was the result of the Mars curing the first layer enough for it to hold its own weight as well as the weight of the layer after it. A 25 mm limit in the bridge test constitutes good performance when referring to resin printers.

The final benchmarking test performed on the Elegoo Mars was the small and precise parts test where corresponding threaded nuts and bolts are printed. This test determines the printer’s ability to maintain tight tolerances and generate precise shapes. The threads of the two components were printed true to scale and without defects so they could be assembled easily and formed a functioning coupling. We noticed some minor wiggle room in the assembly but in no way did it affect the functionality of the coupling.

Real Application Tests

The real application tests were a series of prints the average user would be found to print. They included a set of rings, a Tower of Mordor and a generic tabletop miniature. While there are certainly resin printers out there that could blow the Mars out the water in terms of print quality due to higher resolution LCD screens or higher precision lasers, the Elegoo Mars displayed a beyond impressive performance for its price point. The prints were of a high enough quality that the layer lines were not visible unless actively sought out. The grooves of the miniature’s armour were deep and the finer details such as the lion’s teeth or the cracks in the Tower of Mordor were readily visible.

The Verdict

Ultimately, the Elegoo Mars is a near-perfect initiation for anyone looking to try their hand at resin printing. Armed with its 2K LCD display, this sub-$300 mighty mouse produces models comparable to most $500+ resin printers. The user interface is refined, and the support provided by Elegoo is reminiscent of a family business. With a few quality of life changes, such as a better thought out USB placement, the Mars has the potential to dominate the consumer-grade resin printing market.

Subscribe to the3D Printing Industry newsletterfor the latest news in additive manufacturing. You can also stay connected by following us onTwitterand liking us onFacebook.

Looking for a career in additive manufacturing? Visit3D Printing Jobsfor a selection of roles in the industry.

Featured image shows an Elegoo Mars 3D printer. Photo via Elegoo.