Last week atFormnext 2021, Dutch 3D printing startupBond3D展示了其无效的3D打印技术,供全世界欣赏。

Founded back in 2014, the company claims to be the first in the industry capable of 3D printing functional end-use parts with high-performance polymers such as PEEK without losing the inherent properties of the material.

与传统的FFF不同,Bond3D的专利技术是一个由压力控制的挤压过程,据报道,印刷的细丝以最终的密度高于99%的最终部分结算。所得的各向同性部件保留了其基本材料的庞大特性,就像通过注入成型产生的材料一样。

The problem with 3D printing PEEK

PEEK is one of the better-known thermoplastics in the PAEK (polyaryletherketone) family of high-performance polymers. Combining high strength and biocompatibility with chemical resistance and excellent thermal stability, the jack-of-all-trades material has applications in almost every critical industry.

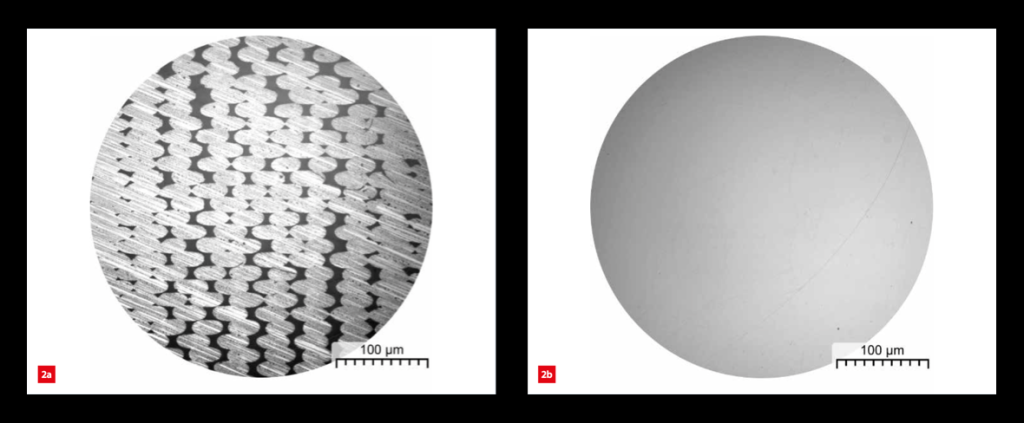

Unfortunately, PEEK is notoriously difficult to 3D print while retaining its mechanical properties. Due to the circular shape of conventional printing nozzles, neighboring layers of extruded PEEK tend to have limited contact areas between them. This results in voids being formed within the parts, meaning 3D printed PEEK components always have a lower density than their bulk material counterparts.

According to Bond3D, conventional PEEK 3D printers are usually only capable of achieving around 85% part density, leading to reduced strength in the z-direction.

带有bond3D的无效3D打印

Bond3D的技术声称要解决这个问题,但是它如何工作?本质上,压力控制的打印过程旨在挤出材料,直到填充先前印刷的线之间的所有空隙为止。该系统确保物料流一直持续,直到喷嘴正下方的熔体池的压力超过一定阈值 - 这是从喷嘴本身上施加的向上力得出的。阈值越过阈值后,先前的层已完全粘合,无需挤出其他材料。

This system of pressure feedback was initially determined by checking the motor current required to drive the extruder, but the Bond3D team found this to be imprecise. The firm eventually switched over to a sensitive force sensor-based implementation, whereby the printhead is mounted on the gantry via a flexure-based, friction- and hysteresis-free assembly.

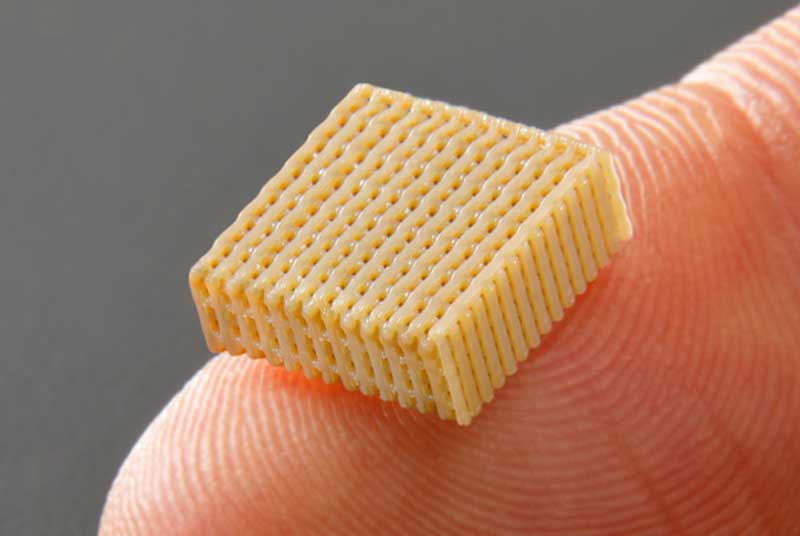

该公司指出,它的生产能力parts that are “virtually free” of microstructural voids, with part densities exceeding 99%. Internal testing on printed specimens revealed yield strengths of 99 MPa and gas pressure resistances in the 115 bar range for wall thicknesses of just 1.4mm. Beyond just bolstering the mechanical strength of printed PEEK parts, this has major implications for their fluid transport properties, which is crucial for any sort of piping or manifold components.

Bond3D获得了数百万欧元的投资from UK-headquartered polymer developerVictrexback in 2019, and is now ready to bring its technology to market following the development of eight production-ready systems this year. The list of potential use cases covers critical applications in everything from aerospace and automotive to medical implants and electronics.

Formnext 2021provided a great opportunity for startups to display the innovations they’d been working on over the years.Quantica, a Berlin-based 3D printing technology developer, announced the launch of its debut 3D printer at the trade show. TheT1 Pro是一种工业级材料喷射系统based on the company’s Extreme Viscosity Jetting process. The system is designed specifically for high-performance multi-material prints using combinations of ultra-high viscosity resins – a niche that inkjet-based 3D printing has not yet addressed.

Arburg’s InnovatiQ subsidiary, a specialist in silicone 3D printing, also announced its latest silicone 3D printer on the show floor –新液体7。Based on the firm’s Liquid Additive Manufacturing (LAM) technology, the LIQ 7 will reportedly enable full-color 3D printed silicone parts for the first time.

Subscribe to the3D打印行业通讯有关增材制造中的最新消息。雷电竞充值您也可以通过关注我们来保持联系Twitter,喜欢我们Facebook, and tuning into the3D Printing Industry YouTube Channel。

寻找添加剂制造业的职业?雷电竞充值访问3D Printing Jobsfor a selection of roles in the industry.

Featured image shows a sample of 3D printed Victrex PEEK made using Bond 3D technology. Photo via Bond3D.