Engineering software developerCoreTechnologieis inviting members of the 3D printing community to take part in an online deep-dive into the capabilities of its4D_Additiveprint preparation program.

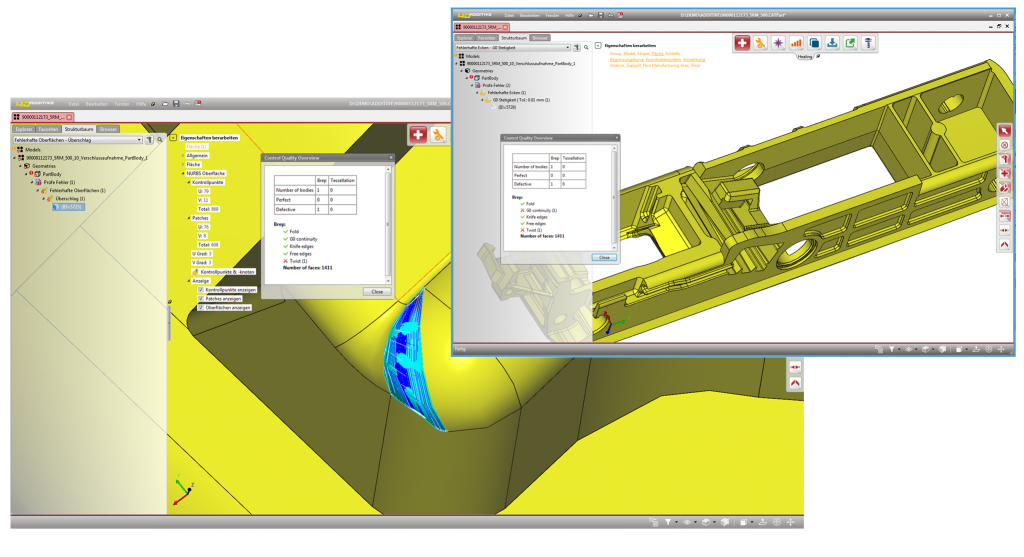

Unlike more basic STL-based pre-processing tools, CoreTechnologie’s software allows users to toggle between precise B-Rep and triangulated 3D models, providing them with enhanced design and repair capabilities. To demonstrate the program’s benefits when used in additive manufacturing, the firm has announced a digital event on April 22nd 2021, and encourages those interested toregister onlineand reserve their place.

The benefits of B-Rep

总部设在德国,CoreTechnologie成矿t up a strong portfolio of data conversion programs, with each designed to expedite different aspects of the part design process. Chief among these is 4D_Additive, a software platform based on a B-Rep (or boundary representation) file foundation, that modifies and repairs CAD models before exporting them to 3D printers.

The program itself features a CAD kernel that is capable of importing geometry as well as Product Manufacturing Information (PMI) from all major CAD packages, without the need for an Application Programming Interface (API). In doing so, the software enables users to get around the use of outdated tessellated models and handle the original data with high precision.

B-Rep also provides a strong basis for 4D_Additive’s direct modelling function, which allows users to rapidly adjust part geometries such as hole diameters and offset surface areas based on exact values. Once ready to print, the models can then be exported into the common 3MF, AMF, OBJ or STL formats, providing engineers with design freedom, without introducing time-consuming conversion steps.

A feature-rich design program

Other benefits of the software include scaling, real-time repair functionality and collision-detection as well as support/lattice generation and slicing output formats. At the end of the design process, 4D_Additive is also capable of organizing part placement within a build space to optimize print quality, providing users with time/cost feedback while allowing them to drive value from their production workflow.

In the months since 4D_Additive’s initial launch, CoreTechnologie has regularly enhanced the software to provide adopters with upgraded features and functionality. For instance, the firm added theISO-recognized STEP formatto its software, enabling users to convert optimized models into a much more accurate file type.

Additionally, the company has introduced a morerobust lattice tool;一个广泛的纹理包含超过5模块,000 textures, as well as a newAI-driven nesting function,进一步增强程序的design clients. Using an advanced AI algorithm, the software is now capable of auto-filling empty areas after pre-positioning, yielding evenly-filled build spaces while avoiding heat nests.

4D_Additive event

In order to demonstrate what can be achieved using its 4D_Additive software, CoreTechnologie has arranged an interactive event for April 22nd 2021 at 11:00 am (EST). Attendees can expect to be walked through a live product demonstration, followed by a Q&A session with company experts.

Those interested in taking part canregister now.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D Printing Industry newsletteror follow us onTwitteror liking our page onFacebook.

Are you looking for a job in the additive manufacturing industry? Visit3D Printing Jobsfor a selection of roles in the industry.

Featured image shows a part being designed using the 4D_Additive Multi Criteria Positioning tool. Image via CoreTechnologie.