前面2017年实体世界峰会that begins on the 20th April, Fried Vancraen gives 3D Printing Industry a preview of what to expect.

Since 2010, the Materialise event has brought together 3D printing industry leaders and provided a forum to discuss not only the current business opportunities, but also how to advance the additive manufacturing industry as a whole.

I asked Materialise’s founder and CEO Fried Vancraen about what Summit attendees can expect, where are the current untapped market opportunities for 3D printing and his vision for the future of additive manufacturing.

The biggest issue in 3D printing

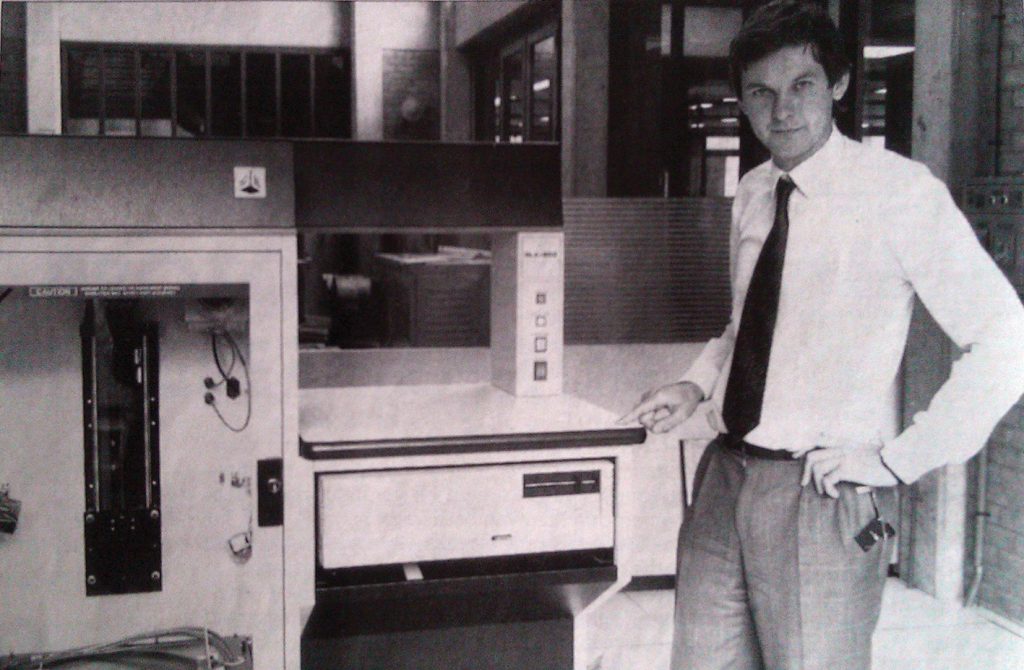

The company that Vancraen founded in 1990, is now valued almost half a billion dollars, and the origins of Materialise are likely to chime with many who use 3D printing technology today: there was problem that needed to be fixed, and no solution existed. So Materialise created the solution.

“We experienced the pain of not having the digital data from the very first day that we had the machine,” says Vancraen of his company’s experience after they purchased an early 3D Systems SLA 3D printer for€250k in 1990. However the biggest issue at that time was the software.

范克拉恩说:“very early on we decided software would be our focus, but to support all the people who develop machines, to support all those people who use machines, even if that was creating competition for us.”

Johan Pauwels, then a work experience student and now Executive Vice President at Materialise decoded the files and Materialise set about developing software to unlock the potential of 3D printing. Vancraen says from those early days he,“recognized 3D printing not just as a fancy new prototyping technology but truly as an industrial revolution。”

3D printing industry co-creation and collaboration is key

Taking place every two years since 2010, the Materialise World Summit has always been more than the standard trade show. From that first event Materialise has brought together 3D printing industry leaders to “thematically address the big issues of the industry。”

Materialise’s vision under the leadership of Vancraen has undoubtedly accelerated the adoption – by promoting awareness of the advantages of 3D printing, highlighting use cases and reaching beyond the immediate world of engineering.

例如,在2012年,Materizize组织了第一个3D打印时装秀。在2015年,关键信息是关于3D打印的有意义的应用程序。

2017年实现世界峰会的口号是“思考。超过。一起。”

范卡恩解释说,即使是大型跨国企业也是“努力使他们的工程团体加速以重新考虑他们的设计和设计方法。这就是添加剂制造(DFAM)的共同创建和设计,这是我们将在世界峰会上解决的主题雷电竞充值。”

首席执行官补充说,“我们相信我们太小了,无法为整个世界带来如此惊人的技术,我们是一个生态系统的一部分,我们与所有玩家一起做到这一点雷电竞充值。”

一个示例是Mictortize的制造服务在Microsoft的Builder3D应用程序中的集成。Builder3D是Windows 10创建者更新的一部分,现在已在新机器上预装,用户可以从i.materialise在无缝的体验中。

制造3D打印的使用不断增长

现在,Mitalize拥有3个业务细分,软件,制造和医疗。该软件部门为当今可用的3D打印技术提供了工具,并且“links to as many types of applications as possible in different CAD systems。”

Materialise software, “supports both the process planning and the logistical planning of 3D printing activities。”

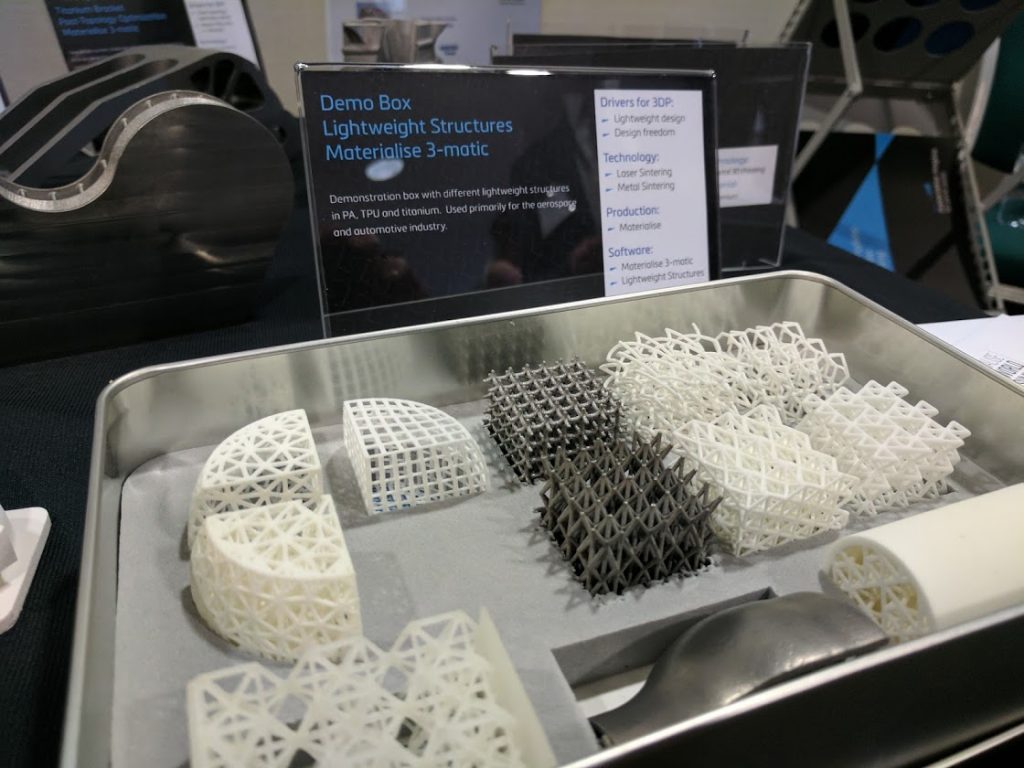

In the manufacturing segment, Materialise has assembled one of the broadest ranges of Additive Manufacturing technologies available anywhere. This segment, “从原型服务开始,但是今天,许多增长都是由制造业驱动的范克拉恩说。考虑到公司正在使用的144个工业3D打印机,谈论物质化未提供的3D打印技术也许更容易。雷电竞app下载

“We cover the different 3D printed plastics, and in metals we are quickly expanding the amount of alloys that we are covering,” says the CEO.

第三是通过软件和服务在医疗方面提供的产品。

添加剂制造的最大低估使用雷电竞充值

从与其软件和制造服务的最终用户进行频繁对话,物质化的位置非常好,可以确定3D打印中的机会和现实世界趋势。

范克拉恩tells me about one particular growing area of use and opportunity that is greater than the frequently reported verticals of aerospace, medical and automotive.

“商业machines is actually the largest segment,” he says. Business machines are the industrial machinery, assembly lines, robots and other capital intensive apparatus of the global manufacturing industry.

范克拉恩解释了:“最大的区别是汽车很大,但几乎完全是原型的。” However the machines used by manufacturing enterprises “are produced in a smaller series than for instance consumer electronics products,” and there is a substantial use of 3D printing to enhance the use of these industrial tools.

企业家和分析师将在实体世界峰会期间仔细倾听,因为商机和趋势的早期识别是经常出现的。

在上一次峰会上,我们谈到了3D打印鞋垫的好处,以及它们如何考虑佩戴者的动态运动。目前,所有标准方法都是基于站立位置而不是步行位置的脚。

Several enterprises are now seeking to address the mass customization opportunities for footwear that 3D printing enables. Vancrean says there “是正在发生的众多范式变化。”

数字骨干

Arguably, software is still the most fundamental part of the 3D printing trifecta that is completed by machines and materials. Concerted effort, and research dollars, are been ploughed into additive manufacturing in a bid to improve speed, reliability and the range of possibilities.

然而, ”制造业世界的一个巨大范式转变,让我们的生态系统,公司如何共同努力,尚未发生足够的变化,无法真正开发出其全部潜力雷电竞充值”,物质首席执行官说。

雷电竞充值增材制造与数字骨架的开发息息相关,这在很大程度上是添加剂制造能够作为技术开发的速度限制因素。我发现数字主链比没有特定材料或打印机的速度更为重要的限制因素,这些是一个技术元素,它们被一个一个人克服。

为3D打印制定新标准

A demonstration of this commitment to industry wide collaboration is seen in the company’s participation in the 3MF consortium.

范克拉恩说,虽然行业标准STL“它的简单性非常强大” at the same time that simplicity brings a lot of limitations. For example, “there is no information about texture or volume。”

Materialise and the 3MF consortium are addressing these limitations.

虽然标准化确实可以发挥作用,但范卡恩认为3MF将更加成功,”因为它是行业驱动的,而不是标准化的抽象。”进一步解释说:“在像3D打印行业这样的快速发展的行业中,实际上,传统的标准生成方式太慢了,无法真正满足公司带来的市场的要求。”

Recognising that the move to 3MF can not be accomplished overnight he says, “我认为3MF应该每5年左右进行一次重大升级,但要保持尽可能稳定。”

下一个被3D打印破坏的市场

我请范克拉恩告诉我他对3D印刷的未来的愿景,也许是他在参考下一个市场而受到添加剂制造的破坏:眼镜的愿景。雷电竞充值

The disruptive impact of 3D printing on the hearing aid and dental industries is well documented and now, “眼镜已经发现了3D打印,并且有一个巨大的机会,因为眼镜本身比助听器和牙齿更大。”

Materialise has worked with Hoya Vision Care for the past several years, embarking on studies to understand how to optimise eyewear for the end user and also add value to manufacturer.

范克拉恩说:“the fact that everybody today is choosing a frame and then putting lenses into it, while in reality you should place the lenses in an optimal way before your eyes and then adapt the frame for it。”

Through 3D printing the, “眼镜的定制正在改变行业的动态,这也可以更好。”

Approximately 30% of all the frames manufactured are scrapped, and not scrapped mid-production but really as finished frames.

Industry 4.0 and the Smart Factory at the Materialise World Summit

“3D打印旨在使制造业民主化,但与此同时,我看到该技术首先达到的行业中的一个大集中化,” for example the hearing aid industry, where the number of players has dramatically been reduced.

范克拉恩说:“ O只有几个能负担得起the full digital chain from customer to product and the hearing aid companies are all buying up the distribution chains and you still have a shop everywhere, but it is a big centralisation。”

The Materialise CEO observes a, “奇怪的平衡开始起源于强大的链,强大的骨干和单个制造商。”

The 2017 Materialise World Summit will be an opportunity to explore and discuss these and other trends in the additive manufacturing industry.

范克拉恩说:“I think the all together approach that we are trying to adapt where we try to imagine what are the big drivers behind our industry, what have they been and what will they be。”

3D Printing Industry will be reporting from the2017年实体世界峰会而且,我们期待着从增材制造业领导者那里听到有关我们行业即将到来的主题的第一手。雷电竞充值

为了了解所有最新的3D印刷行业新闻,与行业领导者的见解和访谈,subscribe to our newsletter和follow us on social media.