这新南威尔士大学(UNSW)已同意在澳大利亚建筑初创公司帮助其同胞卢伊滕fast-track the R&D of a machine capable of 3D printing lunar structures.

Working as part of the ‘Meeka Project,’ the organizations plan to expedite the development and testing of a new gantry-mounted lunar regolith 3D printer. Playfully named ‘Platypus Galacticas,’ the system is designed to allow for the rapid construction of Moon-based infrastructure up to 9m x 12m in size, and ultimately aid Australia’s ambitions to establish a permanent presence on the lunar surface.

“We are absolutely delighted and extremely honoured to be partnering with UNSW to make building on the Moon possible,” said Luyten CEO Ahmed Mahil. “UNSW is renowned for its academic leadership and world class research and we couldn’t be more pleased to be working together. Our partnership will solidify Australia’s leading role in the world’s fast developing space economy.”

“我们对创新和杰出建筑成果的专业知识和热情将有助于人类加快月球和其他行星的殖民化。”

卢伊滕’s Platypus portfolio

Founded just last year, Luyten is a start-up with the stated aim of “bridging the technological gap” between the construction and manufacturing sectors. In an attempt to achieve this, the firm has developed a line of modular ‘Platypus’ concrete 3D printers, which it not only sells for $31-35,850 (USD), but markets as a service for building huge one-off structures.

At present, Luyten’s portfolio includes both the original entry-level鸭嘴兽它更先进远征system. Although the machines feature a similar gantry-layout, the former is designed to make 3D printing complex prototypes viable for architectural newcomers, while the latter is built to provide greater mobility to users, enabling them to scale construction on-site where desired.

这firm has also begun developing another portability-focused edition of the Platypus called the ‘X12,’ which can be transformed into a 12m x 16m 3D printer within twenty minutes. Little is known about the upcoming system, but its scalability is said to be enabled by a robotic transformer, and Luyten has stated that it’s set to be a “robust, mobile and lightweight” unit.

Prior to its Meeka announcement, the company’s technologies had firmly been earmarked for home building applications here on terra firma, with the Southern Hemisphere’s ‘first compliant 3D printed structure’ set to be built in December 2021. However, having identified the cost, pace and customization potential of the Platypus here on Earth, Luyten has now set its sights on extraterrestrial sites as well.

“当我们开发开创性的混凝土3D打印机时,我们认为我们将解决世界各地的建筑和建筑问题,” Mah雷电竞app下载il解释说。“但是,随着目前与整个太空行业的人们进行的讨论,我们现在正在考虑解决月球上的建筑和建筑问题。结果,我们委托Meeka项目。”

Making moves on the Moon

As part of a memorandum of understanding (MoU) between the organizations, the UNSW has now committed to help develop a new addition to the Luyten lineup: the Platypus Galacticas. Being built under the codename Project ‘Meeka’ (meaning Moon in Australian aborigine), the machine is set to be lightweight-but-larger than the other Platypuses at 3m x 4m, as well as scalable and lunar regolith-compatible.

完成后,如果澳大利亚宇航员试图在那里建造一个永久的基地,则预计3D打印机将减少需要向月球发射的机械和材料的数量。通过采用这种基于CAD设计的方法来建立定居点,UNSW副教授Matthias Haeusler说,甚至有可能使它们独特地被月经化。

“With computational design, one has a method to design protective shells for habitats on the moon – with a foremost consideration on requirements for human habitat in mind,” said Haeusler. “[For example], It allows scientific knowledge on how to protect humans from solar and cosmic radiation to feed into a script that generates a shelter with the required 80-plus centimetres of solid material.”

Already, the project is set to be at a stage where the organizations are tuning and testing different lunar materials and designs, but the technology still remains a long way from end-use. If deployed on the Moon, for instance, the Platypus Galacticas would have to be preceded by regolith-mining rovers, which in turn, would need to ferry materials to base where they could be sintered into something printable.

According to Mahil, however, the benefits of developing such scalable technologies won’t just be felt on the Moon but back here on Earth, and the mission is set to yield learnings that inform the construction of housing in extreme climates as well.

“A lot of the daily conveniences that Australians have come to expect, are actually underpinned by space-based technologies,” concluded Mahil. “It is easy to forget that things such as internet access, weather forecasting, GPS, online banking and emergency responses to natural disasters, all heavily rely on the innovations floating in space above the earth’s surface.”

Is regolith-based AM taking-off?

While lunar regolith-based 3D printing remains at an early stage of development, several related research projects have now been backed by national space agencies, with each seeking to investigate its Moon base-building potential.

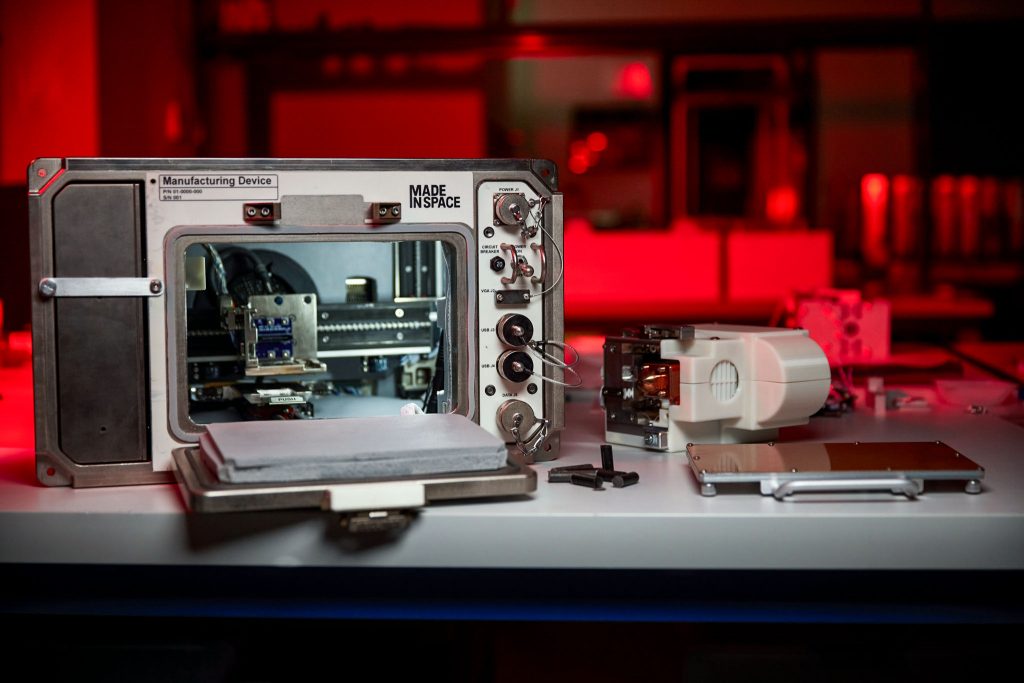

太空系统专家Redwire,,,,for instance, has been contracted byNASA评估3D打印岩石在按需月球结构中的可行性。计划在国际空间站,,,,Redwire的Regolith印刷品(RRP)研究旨在用作“技术演示”,用于使用月尘的原料来创建轨道构建。

Likewise, Texan construction firm图标NASA还委托评估3D打印对生产off World结构的潜力,尽管它是火星而不是月球。使用其瓦肯系统,该公司已经建立了1,700平方英尺“火星沙丘alpha”栖息地,,,,which NASA intends to use as a means of assessing the long-term impact of prolonged exposure to Martian conditions.

在俄罗斯,该国的Roscosmos代理机构已经开始了与3D印刷的类似任务基于Regolith的庇护所,,,,as has中国国家太空管理,揭示了自己的plans to 3D print a Moon base早在2019年1月。

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D打印行业通讯or follow us on推特or liking our page onFacebook。

为了深入研究添加剂制造,您现在可以订阅我们的雷电竞充值Youtubechannel, featuring discussion, debriefs, and shots of 3D printing in-action.

您是否正在寻找添加剂制造业的工作?雷电竞充值访问3D打印作业在行业中选择一系列角色。

特色图片显示了未来Luyten 3D印刷的月球结构的渲染。图片通过Luyten。