BCN3D, a Barcelona-based 3D printer manufacturer, has unveiled its new Viscous Lithography Manufacturing (VLM) 3D printing technology, marking the company’s debut in the resin market.

When asked about a situation where Carbon or 3D Systems might want to acquire BCN3D, he added, “we highly respect if our competitors see us as competition”.

The result of over three years of research and development, the VLM process aims to combine high-performance materials and accessibility into one. Interestingly, the technology will also be a dual-material one, allowing users to print with two different resins in a single build.

该过程的主要销售点之一在于其打印高粘性树脂的能力。得到与化学公司的联合开发协议的支持Arkema, VLM 3D printers will reportedly be able to process resins up to 50x more viscous than industry-standard ones, paving the way for high-strength parts with up to triple the impact resistance and double the tear strength. This includes Arkema Kepstan resin (PEKK).

BCN3D’s FFF history

到目前为止,BCN3D一直保持在FFF 3D打印市场的范围内,建立了大量的挤出系统组合,例如Sigma D25andEpsilon W50。

Late last year, the firm alsoacquired cloud-based additive manufacturing platform AstroPrintin a bid to bolster its software capabilities. Shortly after,BCN3D启动了自己的基于Web的云平台,使客户能够通过实时车队管理,远程构建监控,团队之间的改进的合作等级来简化其3D打印工作流程并扩展其运营。

How does VLM 3D printing work?

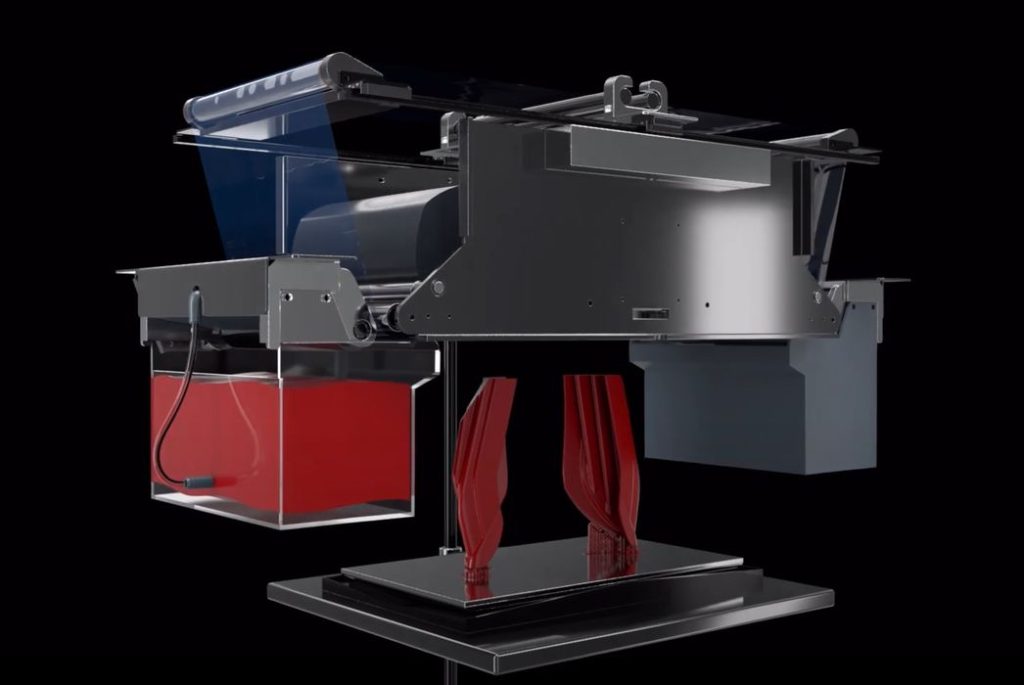

VLM relies on a UV light engine and an LCD screen. But unlike most other LCD 3D printers, the technology leverages a special mechanical system that laminates resin onto a film. This film is transported to the build area where the resin is cured, transferring from the film to the part on the build plate.

Cubicure is one company using a film to transport resin, however the company’s 3D printing systems can also useheated resin to change viscosity。VLM BCN3D告诉3 d印刷行业,在other hand, avoids using heat altogether as they believe it can impact the photoinitiators present in the resin, resulting in unintended changes in properties. In fact, the process relies on low temperatures to ensure printing success, since resins need to remain viscous at all times. In the case of Cubicure, the resins are formulated in a way to ensure properties are stable according to the company.

Since VLM resins can be laminated and cured on two different films, it’s possible to speed up print times and even combine two resins for multi-material parts and soluble support structures – a feature we don’t see at all in the resin 3D printing market – although Dr. Adrian Bowyer did recently share a proposed method forSLA 3D printing with multi-materials。For BCN3D’s VLM method, multi-materials are made possible by simply switching between the films between layers, allowing for multi-colors and even multi-functional components. A section of a part can be designed to be tougher, while another section may be printed to be more flexible.

Resin will be stored in individual cartridges as opposed to a central vat and BCN3D today confirmed that the films will be a consumable part, albeit after hundreds of hours of print time. VLM parts will still need to be washed and cured and cross-contamination between resins is avoided via an unexplained internal cleaning method.

Additionally, BCN3D’s VLM process makes use of monocomponent resins formulations at room temperature, so pot life limitations aren’t a worry. The lamination mechanism also means the machines can theoretically realize zero waste 3D printing, whereby resins can be filtered and recirculated until every drop of material eventually gets printed. In terms of throughput, the technology will be about as fast as competing DLP 3D printers per layer, but with greater material efficiency. The company tells us that this is where the throughput gains arise – in terms of cost per object printed, rather than a speed advantage.

Together with Arkema, BCN3D will continue to co-develop new photocurable materials for VLM. Future resins will include fillers and fiber reinforcements to achieve a wide variety of mechanical performances, including high toughness and impact resistance.

与前瞻性和圣戈巴恩的合作伙伴关系

BCN3D已经与Prodrive,这是一家赛车公司,成为最早对VLM进行测试的公司之一。该公司使用该技术将3D打印的最终用途零件直接集成到其越野汽车中,并指出材料耐用性是该项目成功的关键因素。

Callum Harper, Design Engineer at Prodrive, adds, “VLM allows us to continue to use the engineering materials that we know and love, but instead in significantly finer resolution in all three directions, and the material is much more homogeneous, making the finished parts behave much more like a traditional injection molded part.”

在其他地方,该公司还与汽车玻璃制造商合作Saint Gobain,使用VLM到3D PRINT 7000定位固定装置,每零片在短短7天内以0.79欧元。

VLM定价和技术采用计划

In a press conference held earlier today, BCN3D CEO Xavier Faneca revealed that he has not yet made any concrete plans for a commercial release, but the technology will be available to use as part of the VLM Technology Adoption Program. Aimed at companies of all sizes, the program will see potential customers trial the technology at BCN3D’s Applications Center, where they’ll have a chance to 3D print real parts for their own businesses. BCN3D will use the program for feedback.

VLM 雷电竞app下载3D打印机最终将以低于50,000欧元的价格购买。

Subscribe to the3D打印行业通讯for the latest news in additive manufacturing. You can also stay connected by following us on推特, liking us onFacebook, and tuning into the3D Printing Industry YouTube Channel。

Looking for a career in additive manufacturing? Visit3D打印作业在行业中选择一系列角色。

特色图显示了通过VLM打印的树脂构建3D。通过BCN3D照片。