3D Printing Industry’s series on3D打印和可再生能源转向添加剂制造的角色是在能源领域内更雷电竞充值高效的组件的设计和开发中发挥作用。

“Additive manufacturing will act as a catalyst in some cases and accelerate and drastically improve the performance of systems such as gas turbines, fuel cell systems, and heat exchangers,” says Sebastian Piegert, Department Lead Additive Manufacturing at西门子的能量.

There are a number of projects currently underway at Siemens Energy focused on materials, design, and digitalization in regards to optimizing new component designs for energy applications. Piegert provides an update on the progress the company is making in these areas and shares his insights into the benefits 3D printing is bringing to the energy sector.

虽然在2020年共同陷入困境的所有其他能源领域的需求下降,但可再生能源使用量增加了3%全球能源评论2021. In fact, with green energy继续成长它在能源市场中所占的份额,预计将是worth as much as $2,172 billionby 2030, and as a result, theinvestment in renewable technologies在接下来的十年中,看起来将迅速增加。

西门子的能量’s AM research projects

In previous installments of this series of interviews exploring3D打印和可再生能源,我们听说添加剂制造已经有了雷电竞充值核部门的影响and in the solar industry for the production of下一代光伏. The technology is also being deployed to improve the cost and performancecompetitiveness of the wind energy sector,并且正在利用以帮助氢经济过渡从概念到现实。

Several research and development projects are currently underway at Siemens Energy to investigate how additive manufacturing can optimize materials and part designs within these sectors. Within the firm’sHigh Temperature Applications(HTA) project, the Siemens Energy team is exploring three main areas: materials qualification, new designs, and digitalization.

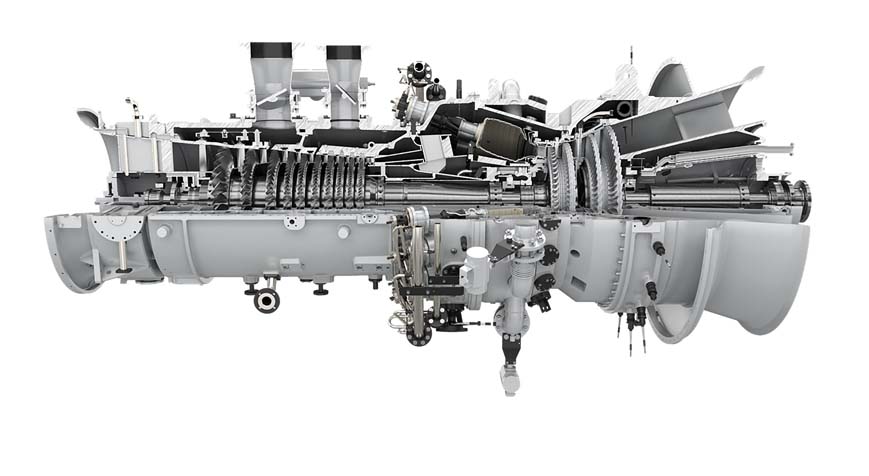

In particular, the team is focusing on optimizing the LPBF 3D printing process to produce highly efficient gas turbine components capable of withstanding temperatures in excess of 1,000 degrees celsius. Additive manufacturing is being leveraged to guarantee the components’ function and service life through the implementation of innovative cooling concepts not technically feasible via conventional manufacturing processes.

“We are exploring the next generation of combustor (Haynes 282) and turbine materials (IN 738) which will enable us to increase the temperatures and the loads in the respective component applications,” says Piegert. “With our partnersBAM,柏林图, andFraunhofer, we are evaluating geometry-dependent material characteristics as well as the limits for recycling the respective powders.”

该项目表明,3D打印可以通过晶格结构和多孔海绵状材料的组合来制造各种通道几何形状,这些材料可以形成更有效的冷却结构。

Piegert补充说:“这些组合提供了令人难以置信的设计机会,以优化流体的混合,调整组件的阻尼行为,并引入更有效的冷却策略,例如蒸腾冷却。”

另一个西门子的能源项目重点是维护,维修和大修(MRO) of gas turbine blade tips using additive manufacturing. The goal of the project is to enable the turbine blades to be operated at higher temperatures or longer operating intervals after repair.

“A fully streamlined repair chain was set up to utilize LPBF for advanced blade tip repair,” Piegert explains. “This is progressing extremely well. The main theme is that repair is not only regeneration of the part in its ‘old’ functionality but we target to provide real upgrades by the advanced repair concepts.”

The application of AM in the energy industry

Additive manufacturing has been deployed to optimize components across various renewable energy sectors, ranging fromGE的设计和制造打火机的努力3D打印的风力涡轮刀片更具成本效益new designs of nuclear reactor componentsmade possible byOak Ridge National Laboratory’s(ORNL)自己novel 3D printing technology.

3D打印也已启用next-generation designs of photovoltaics用于太阳能电池板innovative catalysts for hydrogen production,并为许多制造公司做出了贡献decarbonization efforts.

At Siemens Energy, additive manufacturing is being utilized for numerous components of this kind. One such example is how the technology is being leveraged to improve efficiency and lower the emissions of the firm’s gas turbine engines. The firm’spublicly-funded projectsare working towards a 100 percent hydrogen-operated pilot engine in France, the SGT-400, of which the burners are entirely fabricated via 3D printing.

Last year, the company announced it was working with composite 3D printing technology developerContinuous Compositesto3D print power generator components. With help from阿克马,合作伙伴还揭露了特殊的热固性玻璃纤维增强聚合物(GFRP) material for the project.

“否则,添加剂manufacturing is supporting our Field of Action – decarbonized heat and industrial processes where we dive into applications such as fuel cell systems, heat pumps, and heat exchangers in general,” says Piegert.

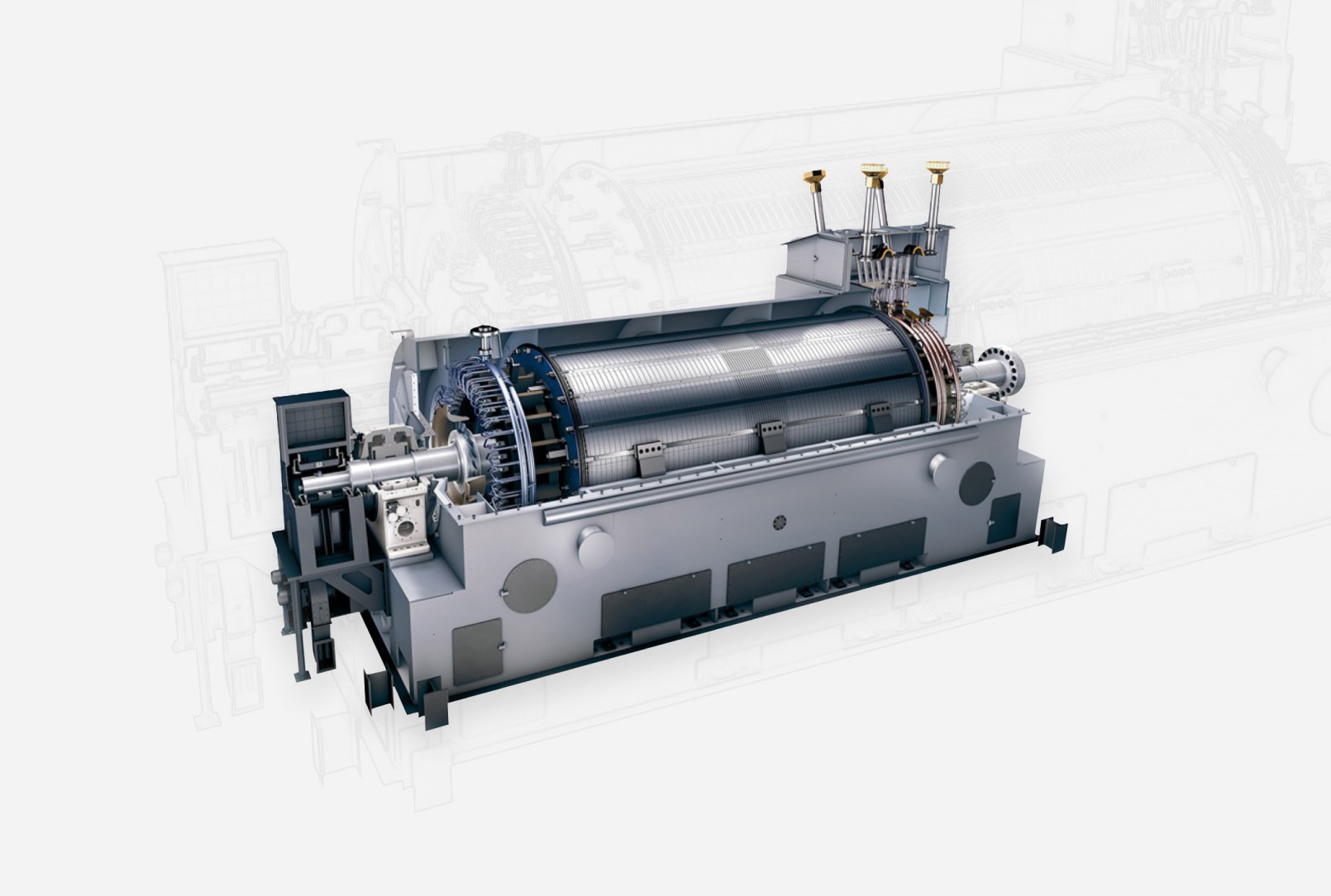

他将昂贵的,高度复杂的燃气轮机及其维护视为当前添加剂制造的最大驱动力,但也将蒸汽轮机,压缩机和发电机视为具有巨大潜力的重要应用。雷电竞充值

In January 2021, Siemens Energy announced it had developed anovel digital repair chain到3D将新功能打印到常规制造的燃气轮机叶片上。全自动链利用了称为Hybridtech的专门开发的激光粉末床融合工艺,该过程将复杂的冷却通道实现为刀片尖端,以减轻裂缝和缺陷的风险。

Siemens is also seeing new and growing demand for the optimization of fuel cell systems and heat exchangers via 3D printing, alongside the technology’s potential for boosting the efficiency of electrolyzers for hydrogen production.

Going forwards, Piegert identifies the requirement for large-format 3D printing for high-end polymers that are potentially fiber-reinforced within the wind sector, in addition to sand 3D printing’s potential for the casting of large, complex parts.

“Due to these industrial applications, we need larger format additive manufacturing capability,” he added. “Huge systems are meanwhile available for polymers and concrete, but also on the powder bed metal market we see movement.

“借助增材制雷电竞充值造,我们将能够更精确地满足客户的需求,因为设计应用程序很快,我们还将根据AI看到更复杂的设计。”

订阅3D Printing Industry newsletter有关增材制造中的最新消息。雷电竞充值您也可以通过关注我们来保持联系推特and liking us onFacebook.

寻找添加剂制造业的职业?雷电竞充值访问3D Printing Jobsfor a selection of roles in the industry.

Subscribe to ourYouTube channelfor the latest 3D printing video shorts, reviews, and webinar replays.

Featured image showsa Siemens Energy generator. Photo via Siemens Energy.