Chinese 3D printer manufacturerFarsoon Technologies首次在其403p打印平台上展示了其双重飞行技术TCT亚洲2021in Shanghai.

The firm also announced it has expanded its material portfolio for the technology with the addition of two new polymer powders and another third party material.

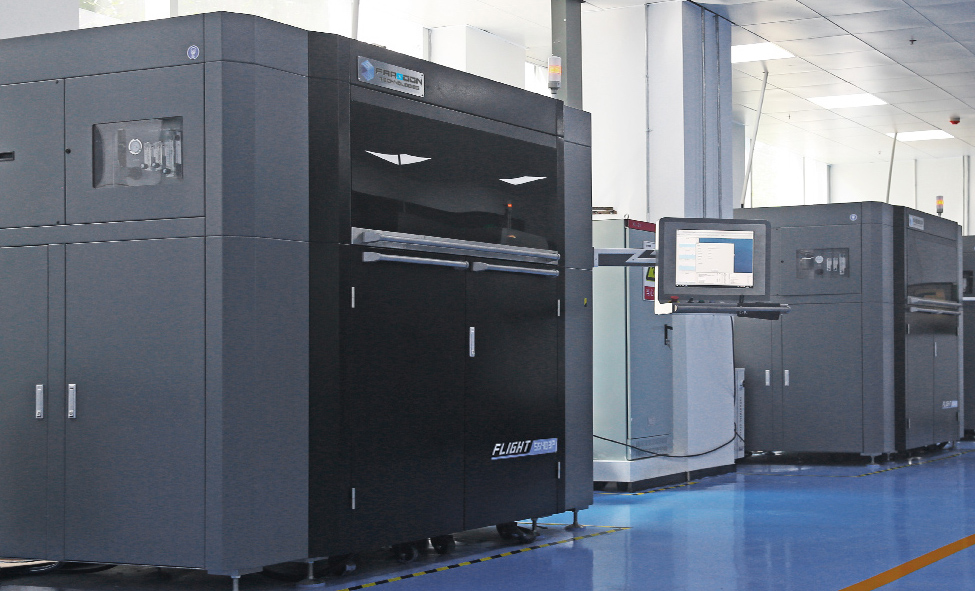

The new dual-laser configuration of Farsoon’s LPBF-based Flight technology is designed to significantly increase manufacturing turn-over rate while accelerating product-to-market cycles of industrial-grade parts such as robotics, electronic components, and battery units.

法苏恩的Flight technology

法苏恩的Flight Technologywas first introduced in February 2019 with the launch of the firm’s403P system, a medium format polymer SLS machine designed for heavy-duty professional applications.

也被称为纤维光技术、飞行中欧ology is 3D printing process designed to enhance the productivity of plastic laser sintering. The process replaces standard CO₂ laser technology with powerful fiber lasers in order to provide increased laser longevity and energy absorption.

In turn, this expands the range of processable materials for Farsoon’s 3D printing systems and also allows the powder to be fully sintered in a shorter amount of time. The high-speed technology wasrolled out for beta testingin October 2019, and has since been continually developed by Farsoon for compatibility with its other systems.

The company’s machine portfolio consists of several machines for both polymer and metal processing, each of which is an open platform to give users access to advanced parameters and third party material usage.

根据Farsoon的说法,其飞行技术“解锁了工业级零件的下一个LPBF生产力”,提供了极为细节的细节,最小的壁厚仅为0.3毫米。

The combination of high-speed sintering and high-feature resolution has opened up multiple applications for the series production of parts including electronic components, robotics, specialized tools and models, battery units, filter modules, and many consumer products.

Last year, Farsoon implemented its proprietary Flight Technology into its new high-temperature252P series of polymer SLS 3D printers.

Dual-Laser Flight Technology

The dual-laser configuration of Farsoon’s Flight technology makes use of two powerful 300w fiber lasers and two dynamic optical systems to create two ultra-fine laser spots with scanning speeds up to 20m/s.

Compared to the single laser configuration, the Dual-Laser Flight technology offers between a 50-90 percent higher production volume rate, and reportedly offers three to four times the production yield of a single CO₂ laser machine.

When used on Farsoon’s 403P printing system, the dual-laser configuration is capable of achieving two full builds of 400 x 400 x 450 mm in a single day. As a result, machine uptime is significantly improved and maximum throughout yield per floor area is achieved within the same time frame.

Farsoon在TCT Asia的403p平台上展示了双重激体配置,并计划将技术集成到其HT1001P CAMS platform, which is equipped with a build cylinder measuring 1000 x 500 x 450 mm.

Expanding Flight technology’s material portfolio

Also announced at TCT Asia 2021 were two new PA12-based powders specifically engineered for Farsoon’s Flight Technology.

The first, FS3300PA-F, is optimized for fiber laser processing and produces parts that offer a decent balance of mechanical and thermal properties suitable for a wide range of industrial applications.

The second, FS3401GB-F, is a glass bead reinforced powder suitable for end-use applications requiring both functionality and mechanical strength. Parts printed in the material display substantial dimensional stability alongside good thermal and abrasive resistance, making them well-suited for 3D printed industrial components such as automotive engine systems and electrical tools.

用户能够利用Farsoon的聚合物powder management system (PMS),在Formnext Connect去年,为了实现新的基于PA12的粉末的粉末刷新率高达20%的Virgin材料,并降低了每零件的制造成本。为此,PMS集成了粉末回收和存储,新的粉末供应,高速混合以及筛分粉末处理过程。

In addition to expanding its own powder portfolio, Farsoon will also include a specialized TPU material from its partnerLEHVOSS Groupfor use with its Flight technology. The LUVOSINT TPU X92A-1064 WT material is light grey in color and has been successfully tested on Farsoon’s Flight 403P and 252P printing systems.

根据该公司的说法,该材料提供了方便的处理窗口和良好的可回收性,同时生产具有良好伸长率和尺寸稳定性的印刷零件。这些功能使材料适合于量身定制的鞋底,具有复杂管几何形状的零件,甚至是医疗应用。

Subscribe to the3D打印行业newsletterfor the latest news in additive manufacturing. You can also stay connected by following us onTwitterand liking us onFacebook.

Looking for a career in additive manufacturing? Visit3D Printing Jobsfor a selection of roles in the industry.

Subscribe to ourYouTube频道for the latest 3D printing video shorts, reviews and webinar replays.

特色图片显示the Dual Laser Flight technology sintering process. Photo via Farsoon Technologies.