内部人士和分析师预测,在我们最新的一系列文章中观看的3D打印趋势,重点是future of 3D printing.

Printpal, a Chicago-based machine learning firm, has announced the launch of its new artificial intelligence-based defect detection software for use with 3D printers.

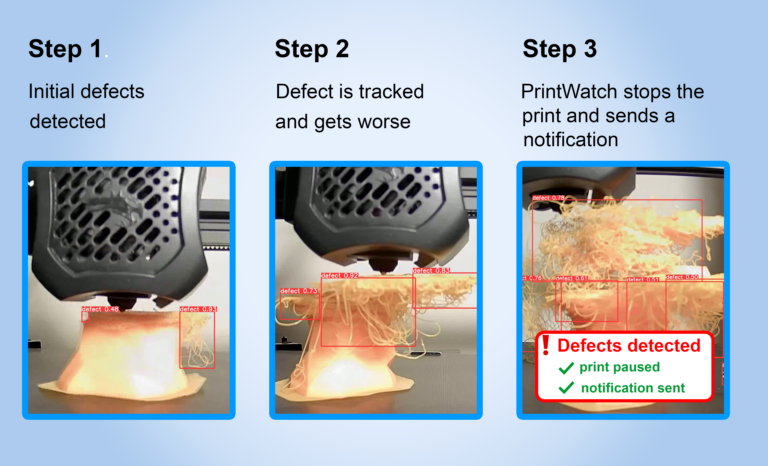

以插件形式出现的PrintWatch使用了指向FFF 3D打印机的构建区域的相机。在利用机器学习时,该软件监视3D打印作业,并确切确定何时实时形成缺陷。PrintWatch能够在3D打印过程中跟踪缺陷,如有必要时采取反应性动作。

According to Printpal, its new software offering is able to abort print jobs, turn off a 3D printer’s heat, and send status alert notifications to users. Essentially, the software is designed to prevent printers from carrying a defective print on for hours, saving time and filament while reducing the risk of hardware damage or a fire.

printwatch– AI-based defect detection

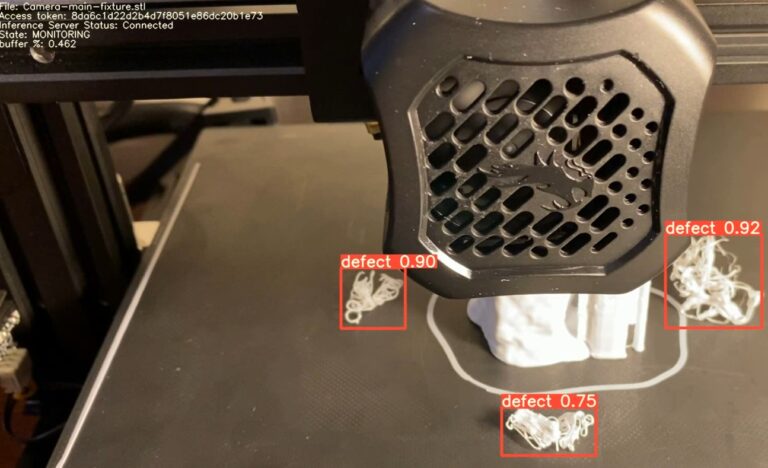

The backbone of the PrintWatch software is its computer vision capabilities. By running the real-time video feed through a proprietary machine learning model, the software can pick out spaghetti-like defects of various sizes, shapes, colors, materials, lightings, and settings. Printpal has trained its detection model using extensive real-world data in dynamic settings, meaning the software will be compatible with any FFF 3D printer.

Once a defect is detected, the software tracks it to see if it is actually getting worse, and only then does it intervene. This tracking approach is what prevents false positives, meaning successful print runs shouldn’t be cancelled by accident.

除了检测缺陷外,PrintWatch还具有始终在后台运行的异常检测系统。该系统旨在检测3D打印机中可能发生的其他异常,例如与轴对齐的问题。异常检测系统可用于找出机器中更细微的问题,从而使用户可以计划任何必要的维护。

Since PrintWatch runs all of its computation-heavy machine learning models in the cloud, users won’t need a high-spec computer to make use of the software. In fact, any system with an internet connection will do, including a simple Raspberry Pi Zero.

How to access Printwatch

可以在此处从Octoprint插件存储库下载和安装PrintWatch插件。该软件还可以作为API提供,可为您想要编程自己的插件自定义集成的更精通技术的用户提供。

printwatchis priced at $9/month for one 3D printer.Each additional printer is $4/month.

Printpal is currently developing a locally running version of the software for use on machines without an internet connection. This offline version will be best-suited for industrial printing operations where network security is of importance.

The company is also working on a number of other AI-based systems for use with 3D printers. This includes software that optimizes the speed and quality of a build by analyzing the G-Code, an inference API for computer vision models that can detect objects, and software that integrates e-commerce into 3D printers.

The 3D printing community has yielded several computer vision-based defect detection techniques in the past. One that comes to mind isthe Spaghetti Detective (TSD), an AI-based softwarethat utilizes the webcam of a printer or home computer to detect when a print job has gone wrong. Much like PrintWatch, once the software sees the extrusion of ‘spaghetti’, it interrupts the process and alerts the user through an email or text message.

Elsewhere, researchers Dr. Joshua Pearce and Aliaksei Petsiuk have also developed their own computer vision-based softwarealgorithm capable of print failure detection and correction. Again, the open-source offering leverages just a single camera pointed at the build plate, tracking any printing errors that appear on the exterior or interior of the part on a layer-by-layer basis.

订阅3D Printing Industry newsletterfor the latest news in additive manufacturing. You can also stay connected by following us on推特, liking us onFacebook, and tuning into the3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit3D Printing Jobsfor a selection of roles in the industry.

特色图片显示了被意大利面条包围的失败印刷品。通过Prusa的照片。