由康奈尔大学已在国际空间站(ISS)成功部署和测试。

As part of an experiment conducted withNASA, 这ISSUS National LaboratoryandHP,康奈尔的建模软件已集成到惠普的空间borne Computer-2为了模拟3D打印过程如何在太空中以获得所需的组件,并预测零件质量。

“以前,由于时间和空间尺度和高热梯度的差异,这在计算上是不可行的,”康奈尔大学设计该软件的博士生Terrence Moran说。“因此,我们使用基于物理的模型开发了该软件,使其可移植并将其上传到ISS。

“It was successfully run and the results were consistent with the results we’d done during our research. The timing and everything were the same.”

AM testing in space

The experiment was one of many carried out over the last year to demonstrate the functionality of HP’s Spaceborne Computer-2, which was installed on the ISS in February last year as reportedly the first commercial edge computing system with artificial intelligence (AI) capabilities.

The Spaceborne Computer-2 is designed to enable real-time processing of huge amounts of data in space and address issues of long latency and waiting times associated with relaying data back and forth to Earth. So far, experiments conducted on the machine range from processing medical imaging to DNA sequencing, and additive manufacturing is also a key candidate for testing, Moran said.

According to him, 3D printing is “absolutely critical to the things NASA wants to do with deep space exploration and going to Mars,” and this has been backed up by several additive manufacturing-related projects undertaken by NASA in recent years.

例如,美国国家航空航天局(NASA)与发射器andVELO3D探索制造3D印刷火箭发动机,并且以前曾与研究人员合作Johns Hopkins University Applied Physics Laboratory(APL) to develop asolar-powered rocket propulsion自己的技术。

3 dprinting has also been used to design and test elements for anAI-powered lunar roverthat could be deployed during NASA’s mission to return to the moon, and in the production of a habitat thataccurately recreates the conditions未来的宇航员将在火星上体验。去年,NASA向ISS推出了一套新的科学实验,其中之一是太空系统专家Redwire到determine thefeasibility of 3D printing regolithfor the on-demand construction of lunar structures.

Most recently, NASA selected California-based aerospace firm火箭实验室到提供启动服务for its upcoming VADR missions. The firm’s Electron and Neutron launch vehicles are powered by its3 dprinted Rutherford engine,,,,which has already beenprinted more than 100 times。

Predicting 3D printed structures in space

For the latest experiment conducted on the Spaceborne Computer-2, Cornell, NASA, the ISS US National Lab and HP teamed up to better understand and predict the deformation and failures of 3D printed structures in space.

在康奈尔断裂组在康奈尔教授德里克·华纳(Derek Warner)的带领下,莫兰(Moran)开发了一种专门的建模软件,能够模拟3D打印过程如何针对特定组件进行效果,以及结果是高质量还是低质量。

雷电竞充值由于缺乏重力,时间和空间尺度的差异以及温度的根本变化,空间中的增材制造可能具有挑战性且无法预测。Moran将他的建模软件称为“虚拟打印的形式”,该软件将在3D打印构建过程中节省时间,材料和数字带宽,与Spaceborne Computer-2结合使用。

1月1日,合作伙伴进行了一次experiment with the modeling software and the Spaceborne Computer-2 to simulate the 3D printing process for a desired component and predict the final structure’s quality. The modeling software proved successful, offering results that were consistent with the results seen in Moran’s prior research.

While the software presents significant benefits to deep space engineering projects involving 3D printing, it could also be an asset back on Earth, too.

华纳说:“ 3D打印的魅力之一是您可以在本地制造。”“因此,关于这一点的整洁是,尽管空间可能是最极端的环境,对于军队,石油钻机或其他地方,但也需要做同样的事情。这表明这是可能的。”

空间as a testing arena

ISS主持了许多项目和实验,负责探索benefits of 3D printing in space。微重力生物打印是一个受到很多关注的领域,尤其是3 dprinting living tissue in space。The likes ofCELLINK,,,,nScrypt,,,,andRedwire’s Made in Spaceall have国际空间站的生物生产商carrying out various3 d printing-based实验which could provide a multitude of benefits for medicine back on Earth.

除了生物打印,陶瓷专家ceramtec生产new generation of ceramic sample containersfor the ISS in July last year, as part of a project with空中客车防御and空间,,,,and theEuropean Space Agency。The containers will be used to facilitate the precision measurements of certain thermophysical properties of metals, alloys, and semiconductors not possible on Earth.

Meanwhile, Redwire has unveiled plans to deploy 3D printing onboard the upcoming“轨道礁”商业空间站,,,,which will be complete with cutting-edge research facilities when launched into Low Earth Orbit (LEO) by 2026. The firm aims to contribute to the space station’s microgravity R&D and manufacturing activities through the technologies of its Made in Space subsidiary, as well as the station’s payload operations and deployable structures.

Subscribe to the3D打印行业通讯for the latest news in additive manufacturing. You can also stay connected by following us onTwitter并喜欢我们Facebook。

Looking for a career in additive manufacturing? Visit3D打印作业在行业中选择一系列角色。

订阅我们YouTube channelfor the latest 3D printing video shorts, reviews and webinar replays.

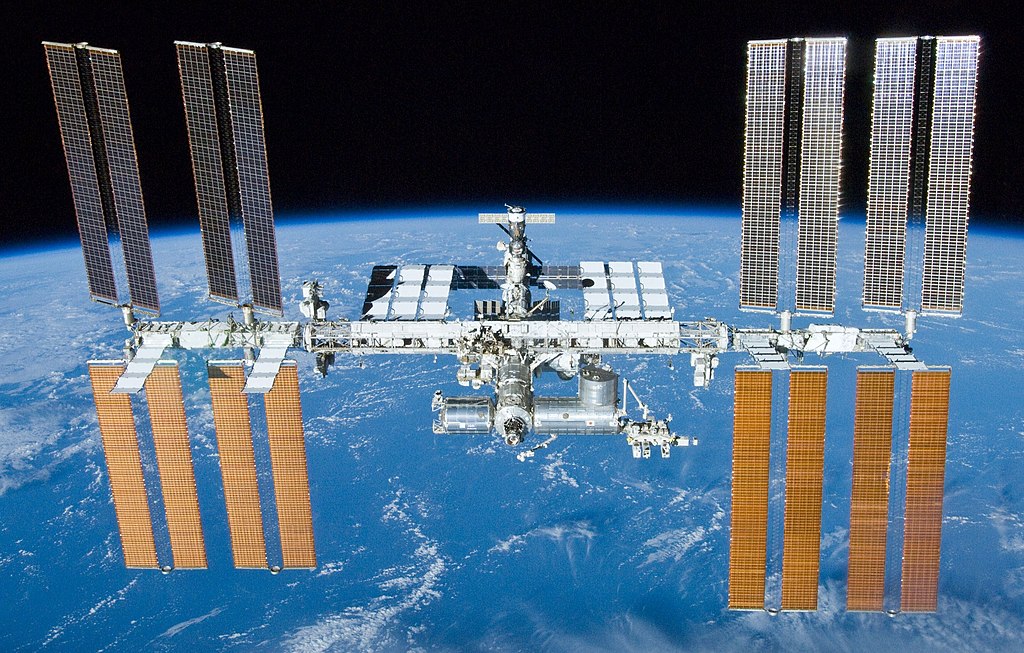

Featured image showsthe International Space Station. Photo via NASA.