这印度海军与印度3D打印服务局合作think3D为了帮助使用增材制造制造零件,以便在近海场景中进行。雷电竞充值

由于使用了旧的进口机械,备件的可用性对于印度海军来说是一个反复出现的问题。与Think3D合作,印度海军试图通过3D打印备件并按需更换它们来解决此问题。Think3D已向印度海军提供了各种3D打印的备件,所有这些零件已成功测试并纳入其机械中。一项特定的案例研究是,该公司分享了围绕离心泵叶轮的更换,这是使用3D打印的船舶运营的关键组件。

为旧机械采购备件的困难

海军船上出现的很大一部分机器非常古老,并从其他国家进口。因此,每当组件损坏时,为这些机器采购备件可能是一个漫长的过程,并且在收到零件之前有重大延迟。对于海军而言,这对于在备件更换之前会保持机器空闲状态,这对于海军的闲置可能会很昂贵。一个这样的例子到达了海军长期以来的需求,以便快速更换其船上的离心泵叶轮。

centrifu叶轮的旋转组件gal pump. It is responsible for transferring energy from the motor to the fluid being pumped by accelerating the fluid outwards from the center of rotation. On ships it is used to import seawater to sections of the ship for regular water needs. Impellers often come in different shapes and sizes according to the amount of liquid to be pumped. They are required to rotate at high speeds for long periods of time.

这breakdown of these impellers has caused major problems for the Indian Navy. These breakdowns are most often caused by the displacement of the eye of the impeller during rotation and by foreign particles in the sea hitting the impeller. As the impellers rotate at high speeds, the aforementioned problems are common occurrences. Replacement parts for these impellers involve a sand casting manufacturing process which often necessitates a 3 month turn-around time to produce a new impeller. Each ship has multiple such pumps and impellers and constant breakdowns have caused a major impediment to the Indian Navy in carrying out its regular tasks.

寻求替代制造过程,可以快速生产这些叶轮,并以较低的所有权成本生产,印度海军将3D打印确定为可能的解决方案,并与Think3D联系。

逆向工程和3D打印叶轮

Founded in 2014, think3D aims to increase the market awareness of 3D printing and its potential applications in India. The company offers services for 3D printing, design, scanning and batch production with other manufacturing processes as well. It also operates a600万美元的3D打印设施为了medical device manufacturing在里面AP MedTech区,印度安得拉邦的医疗设备制造公园。

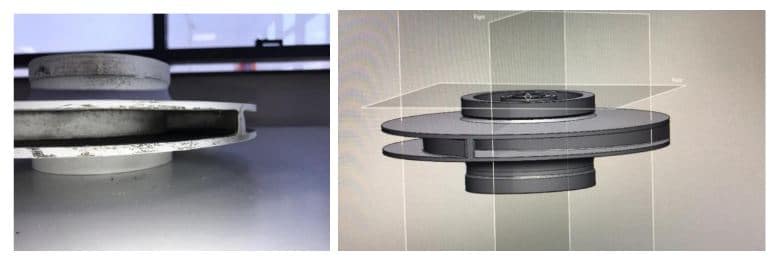

在与印度海军联系后,Think3D团队访问了船只,以详细了解问题并收集有关叶轮的数据,包括所需的材料属性和边界条件。它的第一步涉及3D扫描叶轮和逆向工程。这是使用Einscan Pro+ 3D扫描仪和CREO进行的,以基于扫描的数据创建CAD模型。然后,Think3D使用ANSYS软件研究了哪种材料和3D打印过程将使应用程序受益。测试了各种材料,例如尼龙复合材料,玻璃填充尼龙,PA12,其他常规塑料的适用性。

An important requirement for the impeller material was its damping capabilities, which refers to its ability to convert vibrational energy into other forms of energy without the part breaking apart. Additionally, the part was required to have enough elasticity to withstand the vibrations as well. This ruled out various high strength materials as they were highly brittle, with think3D identifying a material with good damping property and elasticity for the final part. think3D has opted to keep the specific material used confidential.

使用HP的多喷射融合技术,Think3D 3D用所需的机械性能打印了叶轮。然后将CNC用金属衬套加工,以在金属棒和塑料组件之间建立一个接口,这对于旋转叶轮所需的而无需零件破裂所需。在船上进行了测试后,叶轮在所需的小时数中表现出足够的表现。相反,使用3D打印的部分需要3个月的生产才能制造,而生产组件的成本则低40%。与传统生产的叶轮相比,3D打印的叶轮的重量也较低,重量为1公斤,重8公斤至9千克。

With the successful completion of the 3D Printed impeller, think3D has now set its sights on building a digital repository of impellers for the Indian Navy. Once the repository is built, the company has committed to 3D printing the required impellers on demand to supply to the Navy.

Additionally, think3D has also detailed how it has collaborated with the Indian Navy to deliberate an approach for having a 3D printer mounted onboard a ship for when spare parts are needed on demand off-shore, with the CAD designs of the spare parts pre-loaded into the machine. In most cases, this would require the Indian Navy to air-lift parts to the ship or bring the ship back to shore for fitting the components, both of which come at significant cost. think3D is therefore building a customized 3D printer for the Indian Navy capable of additive manufacturing in off-shore conditions.

海上印刷

最近,海事产业增加了对3D打印技术的采用,以打击印度海军所经历的类似问题,主要围绕备件的供应。例如,干散装运输公司Berge Bulk所需的解决方案以更快,更便宜的船只生产备用的插头塞。全球海事产业集团威廉姆森,除了加法制造服务局雷电竞充值Ivaldi Group,,,,3D打印了一套Scupper插头对于Berge散装,可以减少通过传统流程生产Scupper插头所需的成本和时间。

3D打印的Scupper插头是Wilhemsen和Ivaldi Group的一部分。早期采用者计划(EAP),一项计划,向船只和其他船只提供3D打印的备件。该计划在新加坡发起的该计划也加入了该国联合行业计划(JIP)实施雷电竞充值海洋行业的增材制造业。这个jip是由新加坡海事和港口管理局(MPA),新加坡国家添加剂制造创新雷电竞充值集群(纳米)和新加坡船协会(SSA)。

这nominations for the2020 3D印刷行业奖现在打开。您认为谁应该成为今年演出的入围名单?现在有你的发言权。

Subscribe to the3D打印行业通讯为了the latest news in additive manufacturing. You can also stay connected by following us on推特并喜欢我们Facebook。

寻找添加剂制造业的职业?雷电竞充值访问3D打印作业在行业中选择一系列角色。

特色图显示了叶轮的反向工程。通过Think3d的照片。