Scottish aerospace firm阿尔巴轨道has announced the successful use of its PocketQube launchers to fire several miniature satellites into orbit.

3 d打印完全CRP技术Windform XT 2.0composite, Alba Orbital’s low-costAlbaPodsare designed to drive the accessibility of firing small satellites into space. With this in mind, five such launchers have now been propelled into orbit by aSpaceXFalcon 9 Rocket,他们在那里将13个Pocketqube设备部署到课程上,这将使他们从事各种研究任务。

“Congrats to Alba Orbital and to all the teams that have flown with them, for all their hard work,” said Franco Cevolini, CEO and CTO of CRP Technology. “We are very proud to be a part of this, as a supplier of materials and technology that are integration and space-proven!”

“The successful mission demonstrates once again the extreme value of Windform for high-performance, heavy duty and mission-critical applications.”

Windform强化了Albapod

Based in Glasgow, Alba Orbital is a firm focused on becoming a UK hub for helping fledgling satellite projects get off the ground. To best achieve this, the firm doesn’t just offer its support to the innovators behind these PocketQubes, but develops and supplies its own platforms and parts to private enterprises, universities and space agencies around the world.

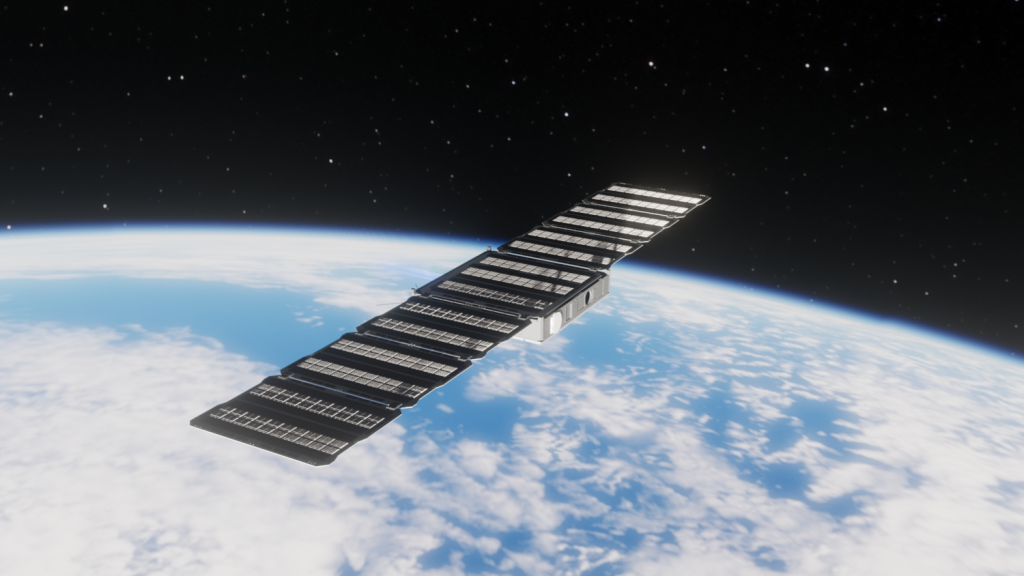

In addition to its ownUnicorn-2satellites, Alba Orbital markets services based around the AlbaPod as well, a deployer it says can drop devices into low earth orbit (LEO) for as little as $100,000. To keep these launchers so low-cost and accessible, while building them tough enough to withstand the rigors of space, the firm has had to refine their production process, including via the adoption of 3D printing.

One way in which the firm has integrated the technology into its deployer manufacturing workflow, is through a long-running partnership with CRP Technology. Back in 2020, the material developer and service provider revealed thatAlba轨道已经开始使用Windform XT 2.0to build its AlbaPods, in a way that yielded accurate and durable prototypes, as well as functional parts.

根据UL 94的易燃性测试,CRP Technology的碳纤维增强复合材料也被评为“ HB”,这意味着它可以接近推进器或助推器的开放火焰。结果,它的开发人员能够与Alba Orbital合作以具有如此可靠性和准确性的3D打印启动器,因此Ablapod计划在2022年晚些时候向LEO进行三次启动,这不足为奇。

阿尔巴轨道’s SpaceX launch

Alba Orbital的“ Alba Cluster 3&4”任务于2022年1月13日启动,可能是同类的第三个任务。SpaceX’s rideshare program,该公司提供的服务以100万美元的价格向轨道发射有效载荷,但它是第一个通过Falcon 9 Transporter-3飞行的服务,并且还看到了迄今已部署最大的Albapod群集。

During the mission, the Transporter-3 fired a total of 105 commercial and government micro and nano-satellites from a launchpad in Cape Canaveral, before deploying them 326 miles above Florida’s east coast. Once they’d reached a polar sun-synchronous orbit, a cluster of 5 AlbaPods helped propel a select 13 of the PocketQubes into position, with four of these breaking new ground in research.

其中一位开拓者是“宽松石 - 阿蒂伯斯-1”,是作为开源项目的一部分开发的Carnegie Mellon University第一battery-le,目的是介绍ss, intermittent, orbital-edge computing nanosatellite. The launch of PocketQube ‘GRIZU-263a’ and pico-satellite ‘PION-BR1,’ meanwhile, marked both Turkey’s and Brazilian start-up派恩实验室’first of their kind to enter orbit.

Notably, among the other launches, ‘UNICORNs 2A, 2D & 2E’ marked Alba Orbital’s first launch of an Earth observation satellite designed to capture images of the planet at night, while teams from the likes ofTU Delft,,,,Ariel University,,,,AMSAT-EA,,,,九头蛇空间,,,,Innova Space和European Space Agency,也将他们的项目脱颖而出。

Since launch, CRP Technology says that these satellites have begun transmitting their findings back to Earth, making the rideshare mission a success. More broadly, the mission also marked SpaceX’s second of 2022, and it has since fired a further two Starlink payloads into orbit, a launch rate that Jonathan Hofeller, the firm’s VP of Starlink and Commercial Sales, can only see accelerating in future.

“我们在消费者和企业方面都有超过100,000个订户,”霍菲勒据说said in a panel discussion at Euroconsult’s annual World Satellite Business Week event in Paris. “And we’re not slowing down. We’re just getting warmed up.”

3D打印准备飞行的卫星

Of course, 3D printing isn’t just used to create launchers or thrusters, but in the manufacture of satellites themselves, often as a means of improving their signal-relaying capabilities. Late last year,Fleet Spaceunveiled plans to launch its“ Alpha” 3D印刷卫星,据说设备具有波束成型技术和所需的专利天线,以解锁IoT应用程序的更大连接。

In 2021,Airbus还揭示了它已将3D打印零件的整合到Eutelsat’srelay satellites, having fitted more than 500switch assembly networks and multi-waveguide blocksto-date. At the time, the firm hailed the lead time and cost benefits of adopting 3D printing within their assembly, and said the resulting satellites would boost broadcast services around the globe.

回头看,喜欢Thales Alenia空间have previously deployedadditive manufacturing in series satellite production也是。当在公司的SpaceBus NEO平台构建中用于制造自定义反应轮托,据说该技术使它们能够合并为一个零件,同时将其重量降低了30%。

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D打印行业通讯或者跟我们Twitteror liking our page onFacebook。

为了深入研究添加剂制造,您现在可以订阅我们的雷电竞充值Youtubechannel, featuring discussion, debriefs, and shots of 3D printing in-action.

您是否正在寻找添加剂制造业的工作?雷电竞充值访问3D打印作业在行业中选择一系列角色。

Featured image shows the 3D printed AlbaPod 2.0 on a vibration table going through pre-flight certification. Photo via Alba Orbital.