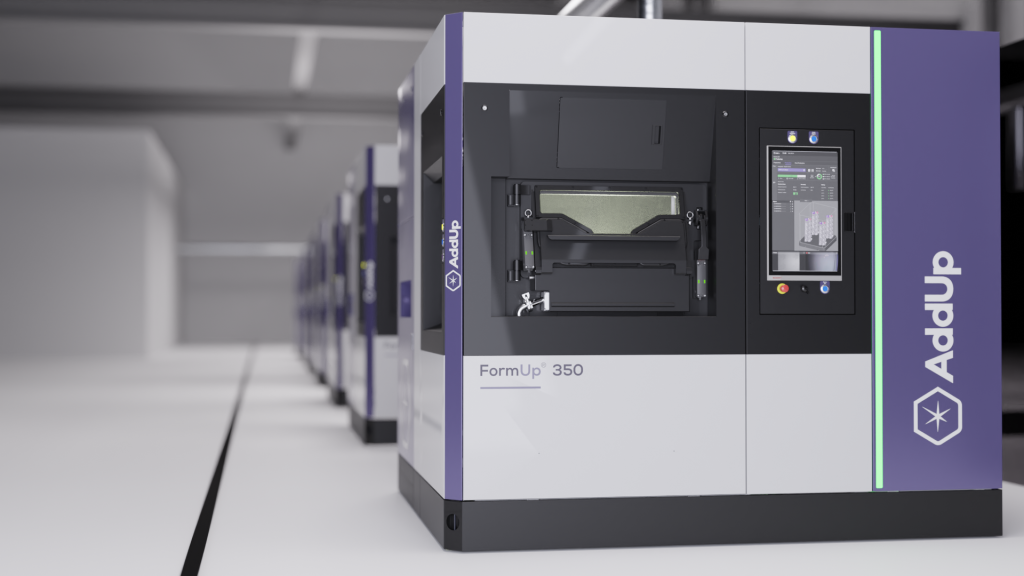

自2021年推出以来Addup的Formup 350 3D打印机通过弥合安全性,生产率和质量,在增材制造业中雷电竞充值引起了波浪。

激光粉床融合系统与大量金属粉末兼容,并根据用户的生产需求提供四种不同的配置。具有高级功能,例如Quad 500W激光设置,双向重新配置系统和每次构建后的自动报告生成,因此机器可迎合研究,航空航天,汽车等等的各种应用。

现在AddUpis launching three new process monitoring software packages to bolster the capabilities of the FormUp 350: AddUp Dashboards, Recoat Monitoring, and Meltpool Monitoring. AddUp believes that its new software suite will accelerate the adoption of its metal 3D printing technology, increasing confidence in part quality for both prototyping and end-use industrial applications.

“The use of monitoring solutions during the AM process could take the place, or at least reduce, the number of post-production inspections that are needed and provide increased confidence in build quality. The integration of in-situ monitoring systems with AddUp machines is a priority on our innovation roadmap. We are committed to providing a fully closed-loop process to our customers,” says Sébastien Devroe, CTO of AddUp. “It is this type of software innovation which will be instrumental in driving AM forward into a fully industrialized technology.”

添加仪表板

第一个监视软件是Addup仪表板,这是一个通用程序,旨在提供3D打印过程的宏观视图。它可作为所有添加系统的选项可用,具有易于阅读的仪表板,可提供实时和历史过程数据,以实现完整的可追溯性和分析。

仪表板用户可以从25多个数据可视化中进行选择,例如图形,热图,交通信号灯和文本 - 所有这些都可以在大小和布局方面进行完全自定义。该软件跟踪80多个制造参数,刷新速度降至五秒钟。测量参数的示例包括:氧气水平,湿度水平,激光状态,在所有移动组件中测量的力,粉末消耗,气体流量状态等。

Additionally, Dashboards comes equipped with an alerting system that sends email notifications to machine operators if something goes wrong with the build. This allows for a build to either be saved or canceled, saving on both time and material costs.

For larger-scale printing facilities or organizations with more than one AddUp 3D printer, Dashboards can collect, consolidate, and display data from several machines at the same time. All systems are collated on a central home screen and they don’t even need to be located at the same manufacturing facility.

Recoat Monitoring

公司监视套件中的下一个程序是重新涂抹监控,该程序可分析350张粉末床中的分层质量。

通过不断检查机器中粉末的均匀性,该软件可以检测到粉末过多或太少粉末的粉末床区域,并在生产过程中自动校正。

In essence, the program triggers a correction sequence whenever it deems necessary to ensure the layering of the powder is smooth across the entire build area. This results in higher part qualities and fewer print failures, and all recoating corrections are tracked and displayed in AddUp Dashboards.

Meltpool监视

Addup即将到来的监视程序的最后一个是Meltpool Monitoring,旨在分析微观量表的打印过程。

FORMUP 350能够在滚动基础上测量几个关键过程参数,包括激光点的物理位置,激光传递的功率以及熔体池的发射率。使用Meltpool监视软件,用户有能力表征构建中的任何缺陷,而不会破坏打印的零件。这对于在原型制定阶段可能有限的迭代率的预算中特别有用。

任何数据收集的Meltpool监测可以在visualized in the company’s dedicated CAM software, AddUp Manager. The data can also be contrasted with the nominal scan strategy, allowing engineers to compare it to expected trajectories.

最终,在系列生产应用程序方面,Meltpool监视特别有用,因为它可用于生成特定构建的基线参考。然后,可以将将来的任何相同的打印运行与参考进行比较,以确保它们从一开始就成功。

如前所述,这些监视解决方案中的每一个都可以在所有添加机器上使用。而且,重要的是要注意的是,用户不必拥有新一代Formup 350即可利用这些新的创新。这些软件中的大多数也可以很容易地集成到形式的先前版本中。

最终,预计整个监视计划都将带来新的流程控制功能,从而使添加剂客户能够具有以前看不见的信心到3D印刷工业金属零件。

订阅3D打印行业newsletterfor the latest news in additive manufacturing. You can also stay connected by following us on推特, liking us onFacebook,然后调查3D打印行业YouTube频道.

寻找添加剂制造业的职业?雷电竞充值访问3D打印作业在行业中选择一系列角色。

特色图片显示了一个添加构造350 3D打印机的机队。雷电竞app下载通过添加图片。