3D打印软件开发人员Authentisehas announced its first-ever acquisition: theElements Technology Platform。

Elements的工作流程工具旨在为制造商提供实时数据跟踪功能,从而使他们能够以优化其生产率的方式组织生产运行。通过购买公司并将其添加到自己的产品中,Authentise认为,现在有可能将3D打印的“灵活性和响应能力”带给“更广泛的制造受众”。

“元素是真实投资组合的完美补充,” Authentise首席执行官安德烈·韦格纳(Andre Wegner)说。“像身份验证一样,元素一直集中在为制造业务提供在大流行世界中需要的灵活性,并具有21世纪的数据效率。”

快速扩张的Ames产品

这真实的制造执行系统, or ‘AMES,’ is essentially a data-driven workflow optimization software. Introduced to allow manufacturers to create a ‘digital thread’ of their factory operations, the platform is full of features designed to enable the real-time organizing and compliance-monitoring of part production.

但是,这并没有停止确定继续寻求有助于扩大AMES功能的合作伙伴关系。仅在过去的一年中,该公司就与Hexagon ABto come up with anend-to-end 3D printing software, and gained EU backing to fund theintegration of digital twin visualizationsdeveloped bynebumind进入Ames,以及adding Solukon’s Digital Factory Tool。

在此期间,真实的合并Riven’snewWarp Adapted Model (WAM) technology艾姆斯,一个平台,可以让用户迅速identify and correct errors early on in the production workflow. Following their integration, it’s said that Riven’s sensors can now gather data before loading it directly into the program’s traceability report, allowing for the full contextual data capture of parts.

Authentise’s Docket integration

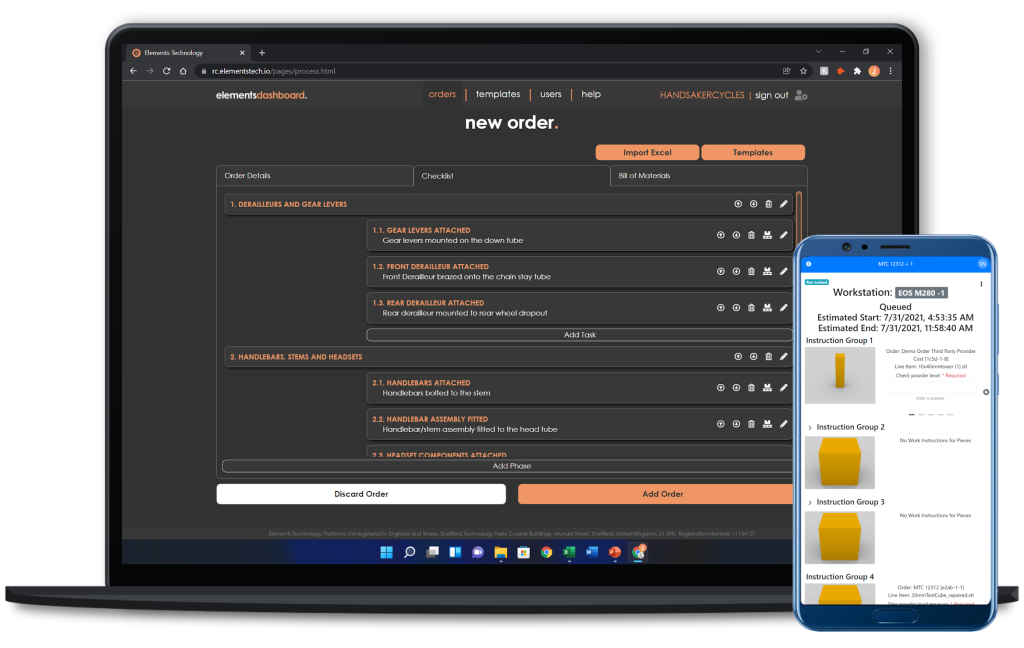

类似于Authentise现有的祭,Elements’ Docket platform is built with part traceability in mind. Designed to function as an extension of manufacturers’ existing enterprise resource planning (ERP) software, the firm’s flagship product effectively allows them to remotely manage their factory floors in real-time.

Currently offered via a £35 per month subscription, the platform is packed with live workflow and intelligent planning features, developed to enable users to optimize their scheduling and access critical data on-the-fly. Docket also allows the results of checks to be recorded via tablet or smartphone, and automatically compiles a list of orders on behalf of manufacturers, helping further digitize their workflows.

“Elements provides customers with a unique self-serve tool for all types of manufacturing operations, to quickly create, capture and access repeatable shop floor processes,” explains Wegner. “Delivering intelligent production planning & scheduling, and real time views of production customers can track orders, like they’re paying for coffee.”

Following its acquisition, Elements’ team will now join forces with their counterparts at Authentise, bringing together a mixture of expertise, not just in workflow management, but machine data insight, AI, RFID technologies and more.

通过这笔交易,Authentises表示,它已经建立了一个开放的数据驱动平台,并有可能重新关注行业4.0,以便具有“实用灵活性”来解决供应链挑战。利用其联合劳动力的经验,该公司还预计,将来,两个团队都将能够通过数据实现“端到端透明度,可靠性和效率”的使命。

Elements Technology的首席执行官Joe Thresaker补充说:“通过数据和现代工具为工人提供支持,为我们提供了更多的制造环境,并使我们能够推动更好的质量,洞察力和全新的业务模型。”“如果没有别的,大流行表明,必须重新考虑事物的制作和交付方式。我们很高兴找到一个了解这一点的伴侣。”

“The last 20 years have been wasted focusing on predictive maintenance and analytics, which have yielded very little ROI. It’s time to refocus on what’s core to manufacturing: the worker.”

工作流监视软件的上升

Using quality control systems, particularly those based around AI, it’s now increasingly becoming possible for serial 3D printing firms to monitor the compliance of parts in real-time, and make corrections to builds where needed.

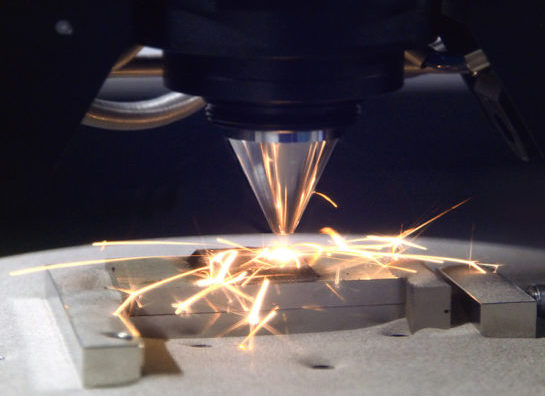

就在上个月Sigma Labs与之合作Materialise开发一种允许的技术校正金属3D打印错误during the production process. The technology has been hailed as a breakthrough by the firms, who say that it could enable adopters to improve the consistency and scalability of their additive manufacturing setups.

同样,研究人员Oak Ridge National Laboratory(ORNL)以前已经开发了基于AI的实时跟踪软件called ‘Peregrine.’ Designed as a low-cost alternative to lab characterization equipment, the platform forms a key part of the ORNL’s ‘digital thread,’ which allows it to track and analyze parts in order to stay on top of defects.

3D Printing Industry is currently seeking feedback on material usage across the sector. Have your say in theSpotlight on Resin 3D Printing Survey现在。

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D打印行业通讯or follow us onTwitteror liking our page onFacebook。

为了深入研究添加剂制造,您现在可以订阅我们的雷电竞充值Youtubechannel, featuring discussion, debriefs, and shots of 3D printing in-action.

您是否正在寻找添加剂制造业的工作?雷电竞充值访问3D打印作业在行业中选择一系列角色。

Featured image shows Elements Technology’s platform having been integrated into AMES. Image via Authentise.