金属3D打印公司桌面金属has been awarded a three-year $2.45 million dollar project from theU.S. Department of Defense(DoD) to develop a high-volume 3D printing process for the mass production of Cobalt-free hardmetals.

桌面金属的专有单通行飞机(SPJ)技术将用于批量制造由新颖的,铁的纳米材料制成的无钴硬质量零件,每天以200,000个机器的价格制造200,000个零件。

“The novel Co-free hardmetal grade is expected to yield a high strength, high toughness, high hardness, and high wear resistance material,” said Dr. Nicholas Ku, materials engineer atCCDC陆军研究实验室(ARL). “We believe combining this novel material with Desktop Metal’s Single Pass Jetting technology will have major applications not only in the defense sector but also in the commercial sector.

“Further, we believe this combined method will dramatically improve sustainability, reduce the use of a conflict mineral and provide an environmentally-friendly process to mass produce parts with superior properties.”

台式金属的SPJ技术

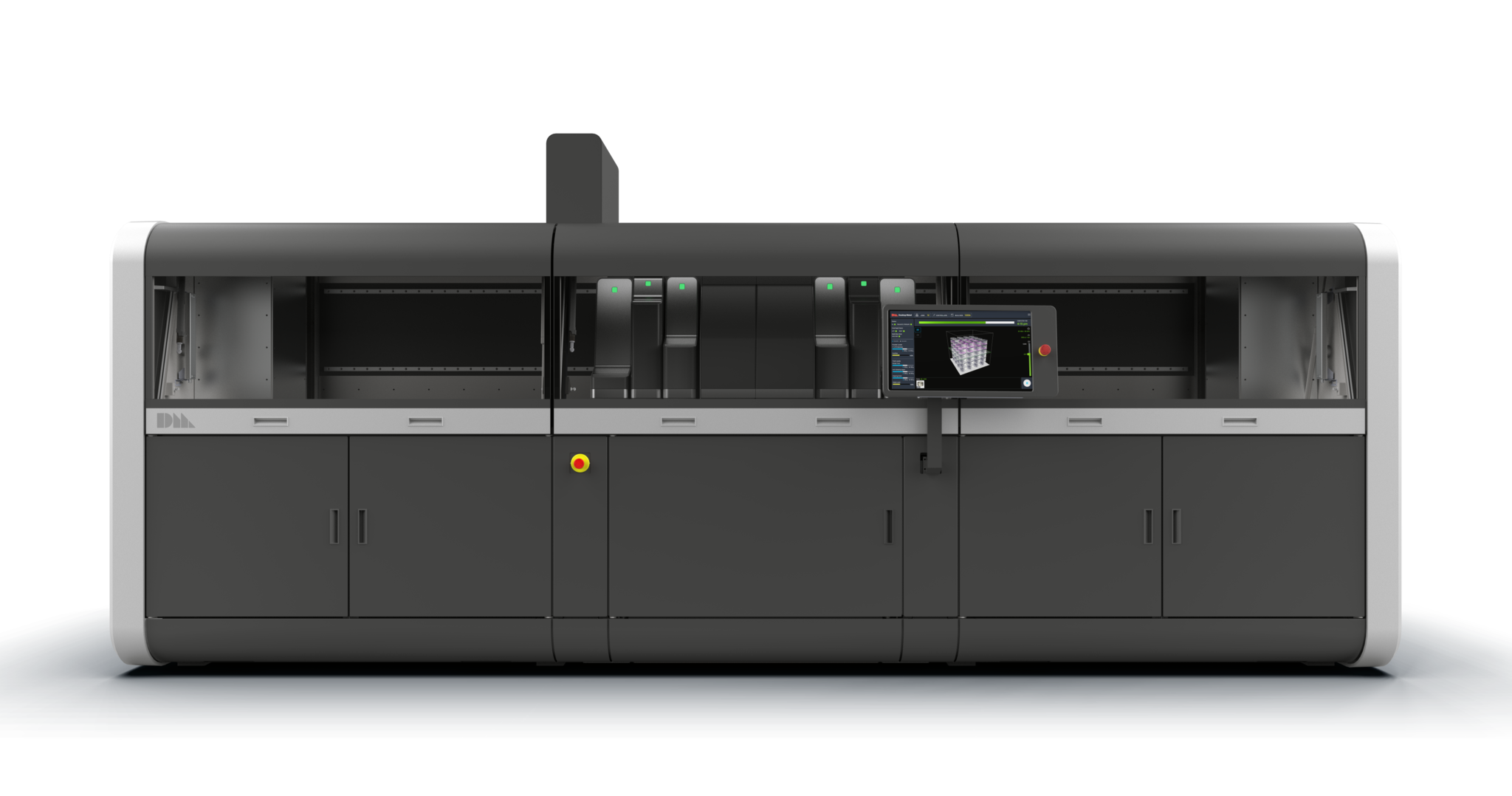

The桌面金属Production Systemis a large scale machine which utilizes SPJ technology – an inkjet and powder-based method of metal 3D printing. In comparison to conventional binder jetting methods, which use multiple carriages and pass over a build box to print each layer, Desktop Metal’s patent-pending bi-directional SPJ technology consolidates these steps into the motion of a single print carriage. This significantly reduces print time and removes unnecessary steps to increase the Production System’s mechanical efficiency.

In fact, the company claims the Production System can achieve print speeds up to 100 times those of legacy powder bed fusion 3D printing technologies.

Chicago-based advanced digital manufacturing company快速半径wasone of the first companiesto receive Desktop Metal’s Production System in 2019, as it looked to further expand its global metal additive capabilities. Shortly after,Ford Motorsalso integrated the Production System toaccelerate prototyping和manufacture limited scale production parts, afterleading a $65 million investment roundfor the firm.

最近,桌面金属与空白支票公司Trine Accelition Corp合并,与3D打印业务公开,此举将看到它在纽约证券交易所列出估计权益价值为25亿美元。公告之后,3D打印行业调查了什么this transaction could meanfor the wider additive manufacturing industry.

Mass manufacturing cobalt-free hardmetals

Cobalt is a naturally occurring element typically used as a metallic binder material for cemented tungsten carbide. While a critical component in items such as lithium-ion rechargeable batteries, Cobalt has also been linked with negative respiratory and dermal side effects, particularly to those who are mining it. The mining of Cobalt also poses environmental issues, such as increased radioactivity levels and polluted rivers and drinking water.

The ARL has therefore been investigating a replacement for Cobalt, culminating in the development of a patented cobalt-free hardmetal material that uses a novel iron-based nano material as its matrix.

一旦开发了材料,美国陆军签约司令部tasked Desktop Metal with providing a cost-effective, high volume process able to print the novel hardmetals, on behalf of U.S. Army Research Laboratory to theNational Center for Manufacturing Sciences(NCMS) and theAdvanced Manufacturing, Materials and Processes (AMMP) consortium。

During the project, Desktop Metal will develop a feedstock and binder system for the cobalt-free hardmetal. Without the use of tooling, the firm’s SPJ process will print the novel hardmetals into complex, net, or near-net shaped parts. The goal of the project is to print at least 200,000 parts per day from a single machine.

桌面金属will also deliver a cost analysis to step up its SPJ technology for the manufacture of at least 500,000 prototype parts. The company believes its SJP process will “lead the development” of a dual-use technology suitable to various commercial and DoD applications.

The carbide hardmetals sector

According to Desktop Metal, the carbide hardmetals market is projected to grow to $24 billion by 2024. Carbide hardmetals are used in multiple dual use applications spanning sectors including oil and gas, chemical and textile, agricultural tools, aerospace, defense, construction, and more.

Desktop Metal特别项目副总裁Animesh Bose博士将担任三年项目的首席研究员。一个家伙ASM国际和APMI国际, Bose has amassed 40 years’ experience in processing particulate materials.

“该项目的成功不仅将为硬质社区提供热切期望的无共同硬质量解决方案,而且还会导致开发一种无工具的处理技术这可以与大多数其他大批量制造技术相抗衡,在硬质及其应用领域开放新的视野。”他说。

It’s expected by the relevant parties that this project will aid in providing a more environmentally friendly way to mass produce metals, alloys, and other composite parts for both DoD and commercial applications.

Subscribe to the3D打印行业newsletterfor the latest news in additive manufacturing. You can also stay connected by following us onTwitter和liking us onFacebook.

Looking for a career in additive manufacturing? Visit3D Printing Jobsfor a selection of roles in the industry.

特色图显示了配备SPJ技术的台式金属生产系统。通过桌面金属图像。