Voting shortlists for the2021 3D Printing Industry Awardsare now open. Who do you think should receive top honors this year? Have your say now.

Researchers at the香港中国大学have developed a polymer-based 3D printing material that can be dissolved almost entirely on-demand.

Made up of plant leaves and plastic waste, the team’s ‘Planstic’ filament features high-entropy fibers, designed to attract natural enzymes that accelerate its rate of degradation once disposed of. After just 8 weeks’ soil decomposition, the scientists say their material completely degrades leaving very few microplastic particles behind, potentially making it an eco-friendly alternative to mainstream PETs.

“可生物降解的塑料的主要问题是,标有'生物降解'的塑料产品只能分解为较小的碎片。这不是对传统塑料的改进,”该团队在论文中说。“ Planstic通过酶降解解决了这个问题,使微塑料的降解反应更加有效,从而加速了它们的降解。”

“Planstic can reduce the costs of dealing with secondary pollution, and can be used generally in daily life to solve the plastic degradation problem worldwide.”

微塑料:全球威胁

尽管它们固有的多功能性,廉价性和耐腐蚀性,但有充分的证明,塑料可能需要数千年的时间才能降解。这意味着,一旦丢弃了基于聚合物的产品,它们就会成为环境的持久污染物,当它们分解成越来越多地进入人类饮食的有毒微型塑料时,这尤其有问题。

While degradable plastic bags are becoming the norm at Western supermarkets, the Hong Kong-based scientists point out that these still cause secondary pollution, via the raw materials and high energy consumed in the process of making them.

同样,尽管一次性食品相关的包装,餐具和容器通常被标记为由可生物降解的塑料制成,但实际上,它们只能被分解成较小的碎片。结果,许多这样的聚合物仍导致了一个越来越多的微型问题,根据最近research,现在使美国人平均每年吃39,000-52,000个聚合物颗粒。

Introducing a ‘Planstic’ solution

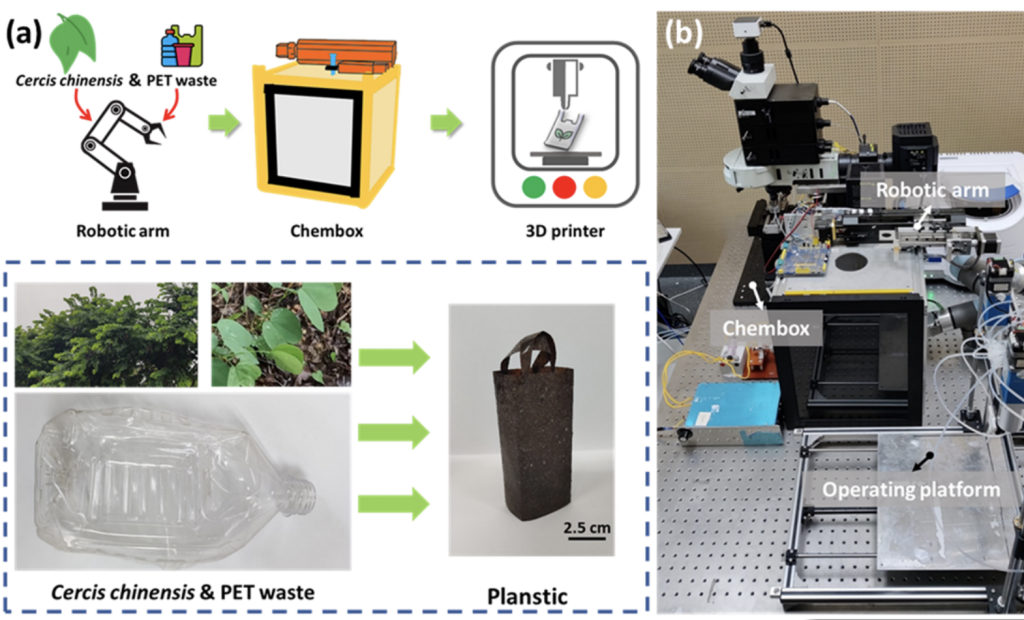

To help the world wean itself off its microplastic diet, the Hong Kong team has formulated a low-cost plant-infused plastic, that harnesses natural enzymes to degrade tiny polymer particles much more efficiently. Nicknamed Planstic, the researchers’ novel material was created via the combination of redbud leaves and ground PET, which were mixed, plasticized and made printable in a ‘Chembox.’

在创建材料的过程中,科学家发现可以从短增长周期中整合叶子Cercis chinensis, which naturally includes long fibers that lend themselves to degradation. The team also discovered that reinforcing these fibers at intersections improved the resulting filament’s properties, while each ingredient’s dosage could be optimized to minimize energy loss.

Once they’d finalized their material, deciding on a mix of 80% fibers and 20% PET, the researchers deposited it using aNanoscribePhotonic Professional GT23D打印机,分为一系列微观结构。在SEM成像表明它可以将3D打印成具有小至160 nm的精细特征的零件之后,Planstic在压力测试下证明自己更灵活,但比普通塑料袋更强大。

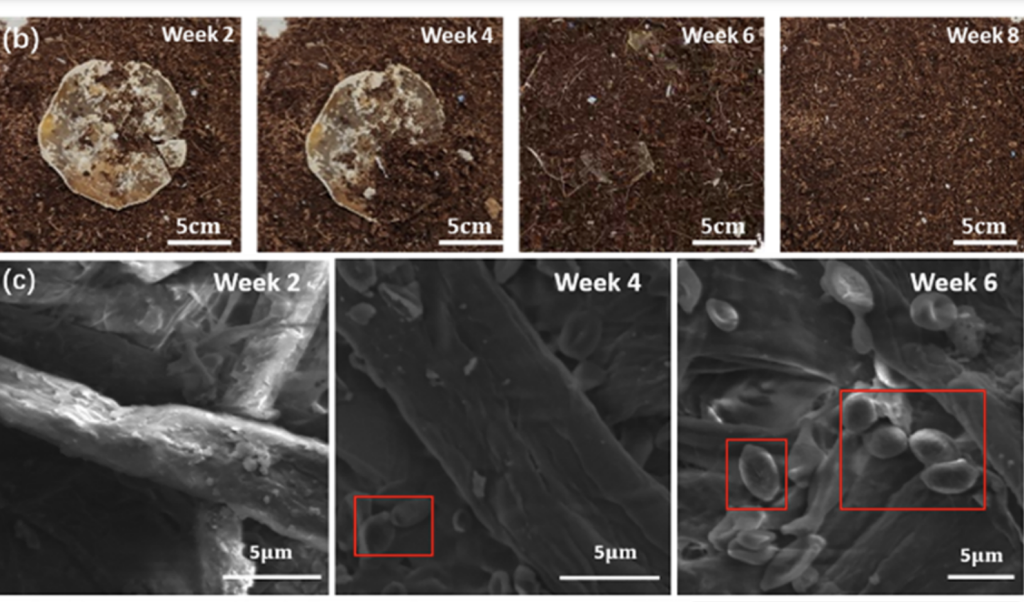

In order to assess their filament’s biodegradability, the team later deposited it into composted soil, finding that the enzymes within its leaf base decomposed “hard-to-degrade substances” like cutin. Interestingly, the material’s less stable surface also improved decomposition rates, as it allowed microorganisms to contact with it and accelerate the process, helping achieve “nearly total plastic degradation.”

最初的成功试验后,研究rchers say their Planstic material proves that “attracting microbials” can “accelerate plastic degradation.” Moving forwards, the team suggest that such closed-loop recycling methods could even replace landfill or incineration disposal methods, “reducing the energy pressure of nanotechnology and [helping] build an environmentally-friendly society.”

推进基于生物的AM

Given that many 3D printing polymers are as much part of the world’s microplastic problem as any other plastic, researchers continue to develop bio-alternatives that incorporate various natural elements, ranging from soil to insect faeces.

Scientists at theMassachusetts Institute of Technology(MIT) have turned to lab-grown wood cells as a means of producing asustainable 3D printable biomaterial他们自己的。通过培养他们的材料,在一个method akin to culturing meat, the team believe that it could be turned into a wood replacement with the potential to be 3D printed into home-made furniture.

On a commercial level,桌面金属has also begun binder jetting wooden parts via its福特wood 3D printing subsidiary. The company is now upscaling waste byproducts from the wood manufacturing and paper industries such as sawdust and lignin, before mixing these with a bio-epoxy resin for architectural additive manufacturing applications.

Elsewhere, in the construction industry,WASPhas utilized natural materials such as soil, rice, husk and lime to 3D print an entireeco-friendly organic house. Finished earlier this year, the self-supporting carbon-neutral ‘TECLA’ home, is designed to act as a proof-of-concept for a sustainable new house building model.

The researchers’ findings are detailed in their paper titled “Planstic: Biodegradable Plastic with High-Entropy Fibers Made from Waste Plastic and Plant Leaves,” which was co-authored by Ziao Wang, Yao Xu, Rulin Liu, and Xi Zhu.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D打印行业newsletter或跟随我们Twitter或喜欢我们的页面Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to ourYoutubechannel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit3D Printing Jobsfor a selection of roles in the industry.

特色图像显示了研究人员“ Planstic” 3D打印丝的生产方法的细分。通过ACS应用聚合物材料杂志的照片。