研究人员at橡树岭国家实验室(ORNL) have announced the development of a novel water-soluble plastic binder that can be added to 3D printing materials and jetted into parts with “exceptional strength.”

By tweaking a high-amine content, low molecular weight polyethyleneimine (PEI), the ORNL team has been able to tailor its properties in a way that doubles its strength compared to conventional binders. To showcase the capabilities of their new material, the scientists have already used it to bind and strengthen silica sand, before 3D printing it into a bridge capable of holding 300 times its own weight.

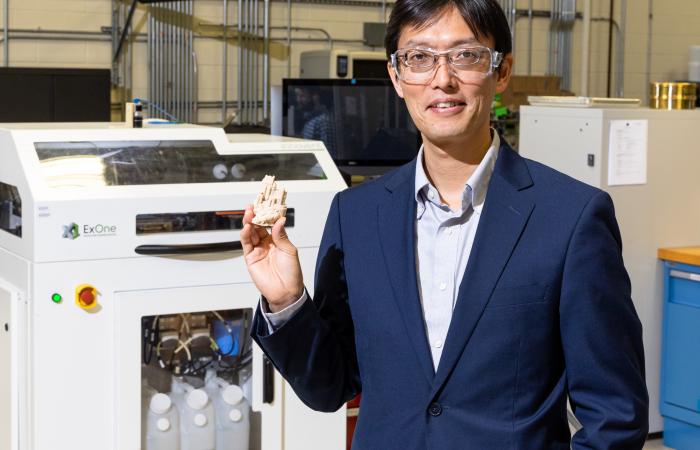

“Few polymers are suited to serve as a binder for this application,” said Tomonori Saito, one of the lead researchers on the project. “We were looking for specific properties, such as solubility, that would give us the best result. Our key finding was in the unique molecular structure of our PEI binder that makes it reactive with cyanoacrylate to achieve exceptional strength.”

Binder jetting’s tooling potential

一个ccording to the ORNL team, binder jetting is both “cheaper and faster than other 3D printing methods used by industry,” thanks to its broad powder compatibility and scalable workflow. In particular, the researchers identify the technology’s ability to process low-cost sand as being ideal for the high-throughput production of industrial tools and dies.

However, the scientists also see the mechanical weakness of green binder jetted parts as a “major bottleneck,” that prevents their widespread adoption in this area. When it comes to reinforcing such parts, binders are a vital element of materials used, that defines their outright strength, but the composition of these often feature limited interactions between the polymer and sand, thus their reduced resistance.

“To ensure accuracy in tooling parts, you need a material that does not change shape during the process, which is why silica sand has been promising,” explainsUniversity of Tennesseestudent and the study’s lead author Dustin Gilmer. “The challenge has been to overcome structural weakness in sand parts.”

In terms of existing 3D printed sand casting molds, the team say that they have limited industrial applications, because once heat and pressure is applied to them, they can be subject to breakage. To enable the production of more robust, scalable, end-use ready binder jetted parts, the ORNL researchers have therefore identified the need for a material that better fuses binders and powders together.

一个new binder on the block?

为了解决传统粘结剂的缺点s, the scientists created theirs from a ‘hyperbranched’ PEI with a high quantity of carbon-nitrogen amines, that allow it to achieve strong interfacial interactions. The material’s structure has also been formulated to provide it with low viscosity, high solubility and limited crystallinity, making it ideal for piezoelectric drop-on-demand binder jetting.

有趣的是,通过尝试粘合剂的PEI负荷,该团队说他们也能够优化其可打印能力,并实现“绿色零件强度的接近线性增加”。通过原型制作,研究人员发现,PEI浓度为5.5%的印刷零件提供了6.28 MPa的强度,远高于他们能够使用商业粘合剂实现的3.60 MPa。

Due to the inherent porosity of binder jetted parts, the team also discovered that they were able to increase the strength of sand components via the integration of a secondary polymer. By adding ethyl cyanoacrylate (ECA), for instance, the scientists managed to create a material that could be 3D printed into a 6.5cm bridge with a flexural strength of 53 MPa, making it stronger than brick-and-mortar.

为了另外的好处,这种注入ECA的粘合剂也被证明是可溶解的,因此其创建者说,它可能具有广泛的“冲洗工具”应用。具体而言,该团队希望这种设备在航空航天和国防行业的优化管道和三明治面板中具有巨大的潜力,他们期望到2025年的垂直行业将增长到70亿美元。

Overall, Gilmer argues that the high-strength polymer sand composite the ORNL team has created, effectively “elevates the complexity of parts that can be made with binder jetting,” and enables the production of intricate hollow forms that “widen [the technology’s] applications for manufacturing, tooling and construction.”

Since the binder was introduced, it has received an研发100奖并获得许可ExOne, where it continues to be used for research purposes.

推进活页夹生产

The binder jet printing market may have been consolidated byDesktop Metal’s acquisition of ExOneearlier this year, but the technology continues to make progress elsewhere too, with several advances being made in the last year alone.

voxeljet, for instance, has revealed that it’s lending its binder jetting expertise to the construction of what is set to be theworld’s largest wind turbine 3D printer。新系统专门为打印铸造大型零件所需的模具GE的Haliade-Xoffshore turbine, which can weigh a colossal 60 tons each.

GE Additive, meanwhile, continues to make progress with its ownH2粘合剂喷射系统, and the company announced a collaboration with theIndiana Economic Development Corporation(IEDC)去年。通过这笔交易,这些组织同意共同投资该技术的研发,并释放了推进该地区工厂自动化并改善其制造准备就绪的潜力。

On a smaller scale, UK-basedMeta Additive还在开发其发展方面取得了进步专有粘合剂喷射技术。The firm gained a £1.2 million英国创新grant to fund the R&D of its high-density, low-shrinkage process in December 2020, and the start-up now has ambitions of marketing it to automotive, aerospace and medical clientele.

The researchers’ findings are detailed in their paper titled “雷电竞充值由聚乙烯粘合剂启用的强二氧化硅砂结构的添加剂制造,” which was co-authored by Dustin B. Gilmer, Lu Han, Michelle L. Lehmann, Derek H. Siddel, Guang Yang, Azhad U. Chowdhury, Benjamin Doughty, Amy M. Elliott and Tomonori Saito.

要了解最新的3D印刷新闻,请不要忘记订阅3D Printing Industry newsletter或跟随我们Twitteror liking our page onFacebook。

For a deeper dive into additive manufacturing, you can now subscribe to ourYouTube频道,包括讨论,汇报和3D打印进程的镜头。

一个re you looking for a job in the additive manufacturing industry? Visit3D Printing Jobsfor a selection of roles in the industry.

特色图片显示了一位Ornl科学家Tomonori Saito展示了使用小说粘合剂印刷的3D印刷的沙堡。通过ORNL的照片。