Smoby,,,,a French toy manufacturer has collaborated with the我PC Industrial Technical Center for Plastics and Composites,,,,和比利时软件提供商,Materialise,,,,tointegrate metal 3D printing into toy production.

合作伙伴共同创建了金属3D印刷模具,以优化微型闪电麦昆汽车的生产,这是动画的主角Pixarmovie, Cars.让·克里斯托弗·伯恩阿特,,,,Project Manager at IPC explained:

“使用金属添加剂制造来生产用于塑料注塑成型工具的主要优点是可以创建保形雷电竞充值冷却通道。这些使IPC能够减少生产周期时间并提高零件质量。”

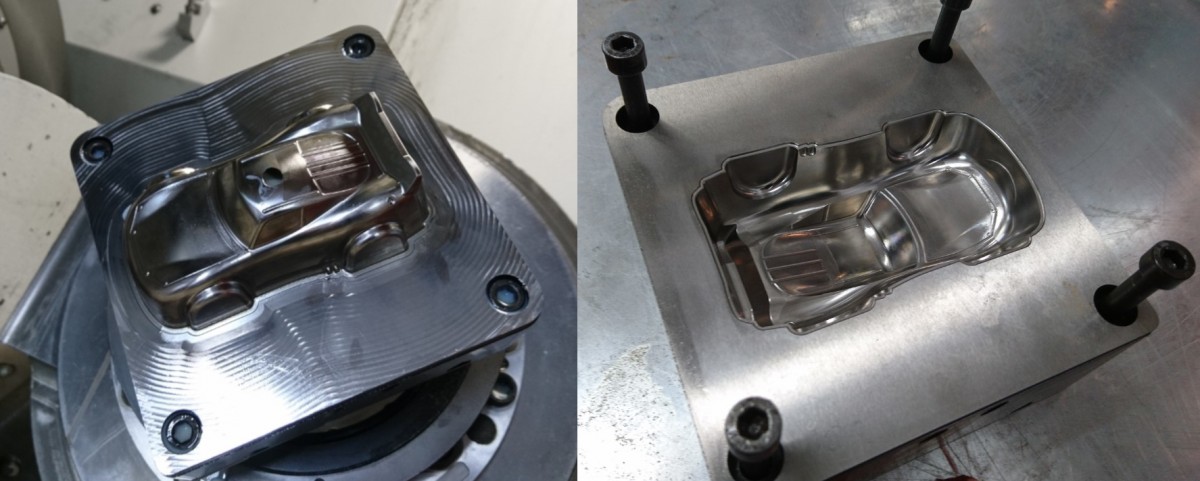

闪电麦昆3D印刷模具

Additive manufacturing has enabled consumers near and far to become makers, which in turn has disrupted the toy industry. Consumers can design and3D print their own toys同时,industrial manufacturers are leveraging the technology’s tooling capabilities.

为了创建闪电麦昆汽车的微型版本,IPC创建了3D印刷金属模具。这样做是因为传统的小系列模具耗时且产生昂贵。

To improve the geometry of the mold, IPC replaced certain solid parts with a lightweight structure usingAltair软件。Then, the Materialise engineering team inserted this design into its3-Matic softwareto smooth the surface and remove all artifacts.

Following this, the open space of the mold was filled with a lattice structure, cooling channels, and lightweight beams, taking into account all specifications for metal 3D printing. Bornéat added:

“实现3-matic软件帮助我们来取代bulk material with optimized lattice structures. This replacement reduces the global volume of the mold and so reduces the AM production time, the cost and the residual stresses on the part. These improvements will allow IPC to create larger molds with better return on investment.”

由于这种合作,玩具的生产周期减少了50%,晶格结构导致上部的材料减少了12%,下部减少了24%。此外,据说优化的设计可以提高扫描速度,而模具的较轻重量可以使具有较大尺寸的模具产生。

3D printing and the toy industry

在2016年Toys “R” Usstores throughout the UK collaborated with Taiwanese 3D printer manufacturerxyzprinting,,,,to makedesktop 3D printers more accessibleto the younger generation.

迪士尼研究,,,,are also developing动画字符with the help of 3D printing and cable driven actuation networks.

Following this,密歇根技术大学约书亚·皮尔斯(Joshua Pearce)教授在研究论文中说:我DIY家庭制造的MPACT在玩具和游戏市场上具有3D打印,,,,’

“It’s one thing to buy a toy from a store or get a commodity toy for your children. It’s perhaps more valuable to get that exact, specific toy that your kid really wants that you can either design yourself or download and customize on your computer and print at home.”

提交您的nominations现在参加2019年3D印刷行业奖。

Also, for the latest 3D Printing Industry news subscribe to ournewsletter,,,,follow us on推特and like us onFacebook。

Looking for a fresh start in the new year? Visit3D打印作业to commence your new career.

特色图像显示了由3D印刷金属模具创建的微型照明麦昆汽车的原型。通过物质照片照片。