China-based 3D printer manufacturerEplus3Dhas made its debut in the railway sector with its latest customer project.

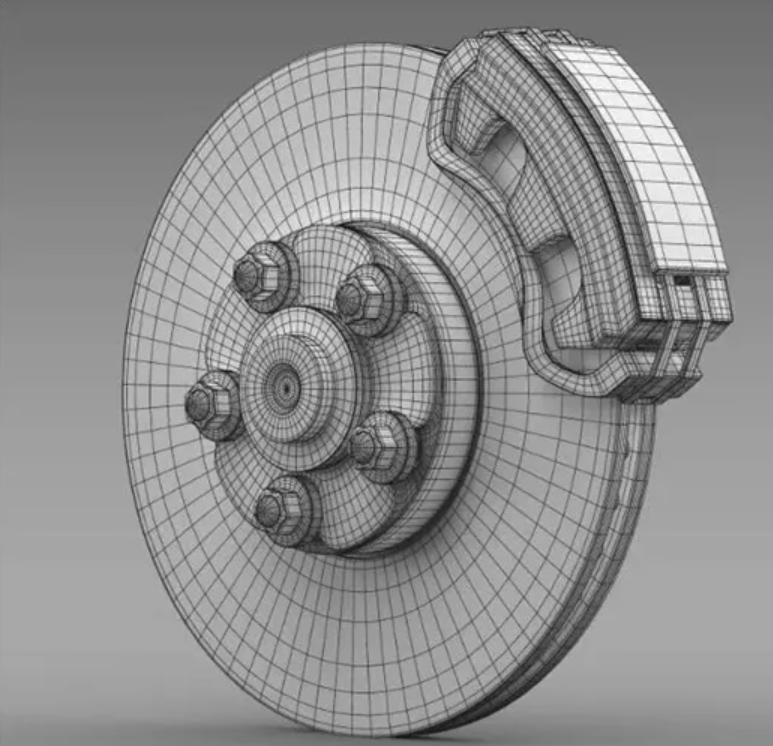

Working closely with an unnamed railway company, the firm used its large-formatEP-M650systemto 3D print a set of custom end-use brake discs for use on a train. Measuring Φ 648 x 90mm³ each, the parts were printed using 24CrNiMo alloy steel with a total build time of 631 hours from start to finish.

用例是EPLUS3D的3D打印应用程序中最新的用例,据报道,与传统生产方法相比,铁路公司的成本和较短的交货时间。

The need for high-performance brake discs

像航空航天和汽车一样,铁路行业建立在高性能金属零件上。当今的高速火车可以以约350公里或更高的最高速度行驶,每辆马车重约60吨。因此,移动的火车在其背后有大量的惯性和动能,这使得在短时间内制动和停车变得非常困难。

制动盘仅通过互相压力来起作用,这会产生摩擦以抵消火车车轮的旋转。不幸的是,如果不产生热量,您就无法摩擦,因此经常需要制动盘(和制动垫)以承受约900°C的高温。它们还设计为在各种雨天,雪,沙子和阳光下工作。

Many of today’s brake discs are made of steel alloys and manufactured via conventional processes such as metal casting and forging. While these approaches do deliver excellent mechanical properties and surface finishes, they also suffer from excessively long production cycles. This is particularly troublesome when sourcing spare parts for replacements, as deliveries can take several months to complete with added costs at every step of the supply chain.

A new tool for the railway sector

Taking the additive manufacturing approach, Eplus3D made use of its EP-M650 3D printer, a quad-laser powder bed fusion system with a large-format build volume of 655 x 655 x 800mm.

这台机器是与大量的兼容metal powders such as titanium, aluminum, Inconel, cobalt chrome alloys, and more. The 24CrNiMo steel used for the project is known for its high tensile strength, fracture toughness, and excellent thermal stability – crucial properties for brake discs.

除了将自己的交付时间和较低的生产成本贷款外,3D打印的使用在零件性能方面也有几个好处。根据Eplus3D的说法,由于高功率激光束的反应性,3D打印的制动盘可提高密度,从而获得更好的机械和摩擦特性。由于表面特征和孔被打印为一个整体部分,因此还发现制动盘可提供优质的散热。

Ultimately, Eplus3D sees a bright future for its 3D printers in the rolling stock sphere, providing a new and improved method of fabricating critical spare parts without sacrificing part performance.

即便如此,EPLUS3D并不是第一家利用运输领域增材制造技术的公司。雷电竞充值刚刚,阿尔斯托姆,一家位于法国的滚动股票制造商,采用了FDM 3D打印技术Stratasysto简化其自己的备件生产操作。该公司的最新项目之一是为阿尔及利亚的Sétif电车道生产一套紧急备件,大幅度削减了交货时间,并节省了成千上万的制造成本。

Elsewhere,Kimya,技术公司的雷电竞充值增材制造材料部门盔甲,使用3D打印到产生过时的保护盖组件对于不愿透露姓名的铁路供应商。早在1982年开发,盖子的模具不再存在,因此备件必须从头开始重新设计,然后在3D中打印在Peek中。

订阅3D打印行业newsletterfor the latest news in additive manufacturing. You can also stay connected by following us on推特, liking us onFacebook, and tuning into the3D打印行业YouTube频道。

Looking for a career in additive manufacturing? Visit3D Printing Jobs在行业中选择一系列角色。

特色图显示了数字制动盘设计。图像通过Eplus3d。