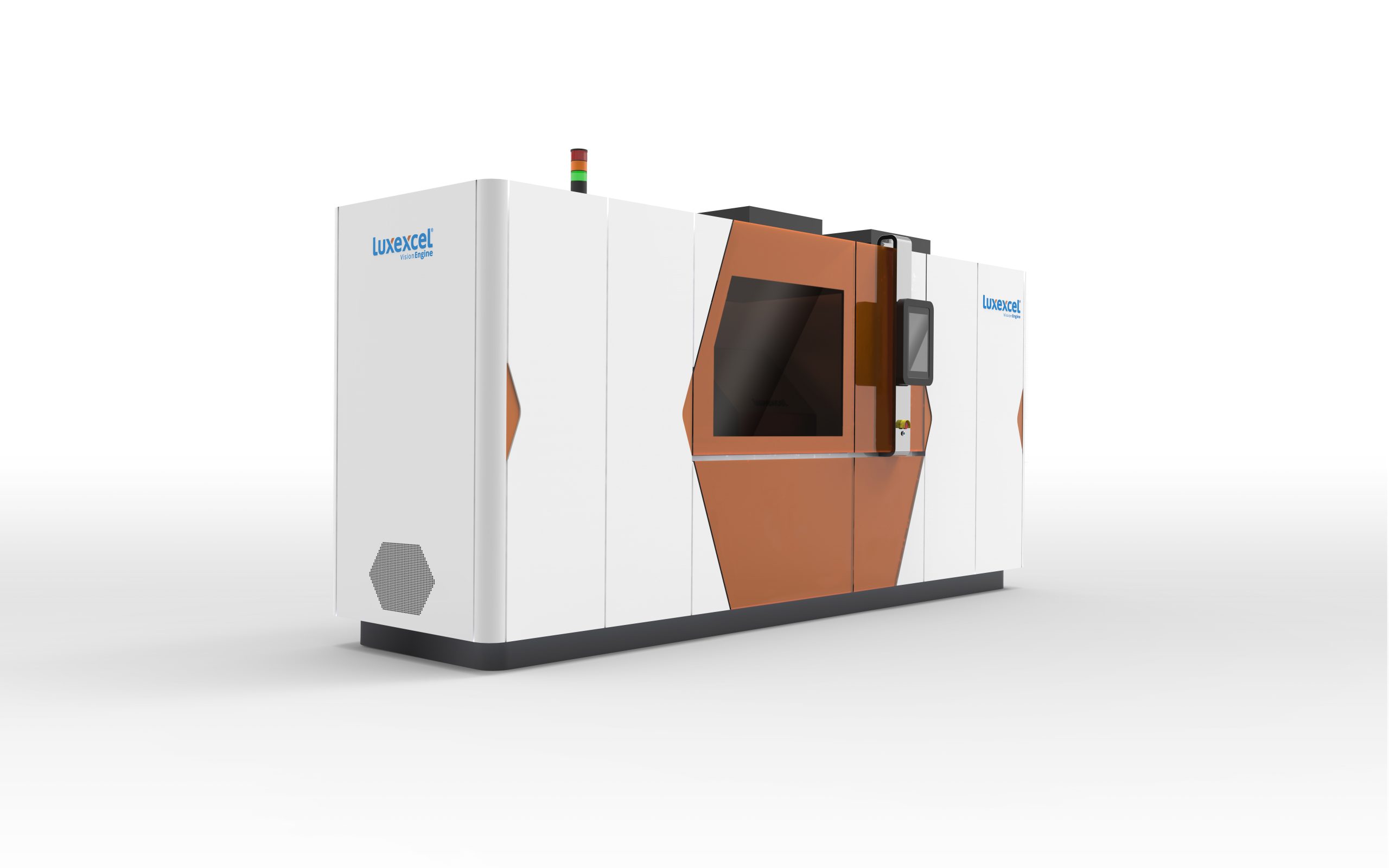

Luxexcel是3D打印处方镜的专家,已经启动了VisionPlatform 7,该平台使制造商能够将3D打印的处方镜头集成到智能眼镜的生产中。

Developed in response to market demand, the platform includes new features that facilitate the manufacture of lightweight, thin prescription lenses for use in commercial smart glasses frames. VisionPlatform 7 combines high-tech hardware, proprietary materials and advanced software to manufacture the lenses, which can be used by companies seeking to accelerate their Augmented Reality (AR) eyewear projects.

“The launch of VisionPlatform 7 begins a new era in the manufacturing of prescription smart lenses,” said Fabio Esposito, Chief Executive Officer at Luxexcel. “To compete in the race to launch consumer-ready smart glasses, eyewear manufacturers need to address prescription in their smart glasses devices. Luxexcel provides a disruptive solution where smart technology is seamlessly combined with a prescription lens, rather than adding prescription power to the smart device as an afterthought.

“ Luxexcel通过允许技术公司在自己的制造业中制造处方智能眼镜来加速市场的推出。”

3D printing prescription lenses

Luxexcel was founded in 2009 in the Netherlands, and focuses on 3D printing prescription lenses using itsproprietary hardware, software and materials. The company’s technology is based around its Vision Engine process, which jets a VisionClear resin onto a build plate before photocuring it under UV light.

该技术使得直接印刷在玻璃或聚合物上,使其与商业眼镜框架兼容。这些镜头也是可自定义的,可以在框架的层之间插入胶片或LCD屏幕,从而使它们具有AR能力。

Luxexcel received a$14.7 million cash injectionin 2017, and a further$13.9 million in 2018, to develop its 3D printed lenses. Using the funding, the company has steadily ramped up its production capabilities, reaching a landmark of5,000 prints per yearin February 2019, and later50,000 lenses in December last year.

遵循teaser announcement last year该公司与波导制造商合作波动in February to3D print prescription smart glasses具有AR功能。通过其合作伙伴关系,两家公司将生产标准化的镜头模块,其他智能眼镜制造商可以使用这些模块来创建最终用途设备。

Features of VisionPlatform 7

The launch of Luxexcel’s VisionPlatform 7 follows a successful product demonstration earlier this year, which illustrated how a prescription lens, a waveguide, and a projector could be combined into a 3D printed prescription lens with AR capabilities. The company’s family of custom materials ensured these integrated components were able to bond sufficiently with the prescription material.

The platform also prints critical features, such as the air gap required for a waveguide, that are otherwise difficult to manufacture without birefringence – which refers to when an incident ray of light is split into two rays that are polarized at right angles or in opposite directions.

VisionPlatform 7“不可知论者”技术和卡帕ble of integrating a variety of objects during the 3D printing process to create prescription smart eyewear. The platform prints a range of powers from high and low and on diameters spanning one to 65 mm. Luxexcel’s materials have strong adhesion properties and are capable of withstanding high temperatures. This ensures that a range of anti-reflective and hydrophobic coatings can be applied to the lenses as part of the firm’s existing ophthalmic post-processing steps.

As part of the 3D printing process, a hardcoat is integrated into the lens with an even surface in order to protect the smart technologies within. Custom lenses can also be printed to address common refractive errors, such as single vision and freeform lenses and multifocal progressive designs.

VisionPlatform 7 is capable of actively adjusting and aligning key process parameters to ensure the technology’s reliability, quality, and high yield. As such, the 3D printed lenses produced by the platform meet ISO, ANSI, and FDA requirements for prescription eyewear.

“To manufacture a device that combines prescription and smart functions requires a combination of skills in technology and optics,” said Guido Groet, Chief Strategy Officer at Luxexcel. “It can be difficult to find this combination of skill sets in one team, so we offer this experience to our partners. We provide our customers with a complete solution to manufacture prescription smart lenses so that they can focus on developing the technologies and content for the device.

“With VisionPlatform 7, more innovative features can be added to smart glasses and the only limitation is the imagination of the designer.”

Nominations for the2021 3D Printing Industry Awardsare now open, have your say who is leading the industry now.

Subscribe to the3D打印行业newsletterfor the latest news in additive manufacturing. You can also stay connected by following us onTwitterand liking us onFacebook.

Looking for a career in additive manufacturing? Visit3D Printing Jobsfor a selection of roles in the industry.

Subscribe to ourYouTube频道for the latest 3D printing video shorts, reviews and webinar replays.

特色图片显示a 3D printed prescriptive lens integrated with a waveguide. Image via Luxexcel.