来自特拉华大学(UD)发布了一份新的研究论文,探索了将生物量升级为新的3D印刷材料的方法。

由国家科学基金会不断增长的研究(NSF GCR)程序,该论文专注于木质素,这是制作纸产品所留下的废物,并证明可以通过他们声称具有类似石油的方法具有竞争力的方法来有效地将其有效地转变为基于生物的3D打印树脂基于产品。

“能够采用技术木质素之类的东西,不仅将其分解成有用的产品,而且要以成本和比石油材料低的环境影响来做的能力,这是没有人真正能够真正能够真正无法做到的。以前展示。” NSF GCR领导UD的Thomas Epps说。

Repurposing lignin for 3D printing

木质素是一种化学物质提供力量和圣iffness to plant cells walls, and is produced endlessly by plants to protect themselves from predators. As such, lignin is a widely available resource, with about 100 million tons of technical lignin waste generated annually in pulp and part mills around the world, UD says. While the researchers claim their research to be unique, there has been progress in this area by several other universities and 3D printing firms, too.

2020年,来自University of Freiburg将木质素与纤维素呼叫结合在一起,以开发自己的环保友好型基于木材的3D打印材料。生物合成聚合物在轻型构造或工业应用中具有潜在用途。

别处,麻省理工学院scientists developed their自己的实验室种植的木单元包含木质素增强的墙壁,可以构成新的,更可持续的3D可打印生物材料的基础。尽管仍处于早期阶段,但未来的研究可能会作为3D印刷环保家具或生产合成森林的一种手段来解决日益增长的全球森林砍伐危机。

到目前为止,这一领域最显着的发展也许是桌面金属’s新的Forust Wood 3D打印技术去年中途推出。该工艺将木材(例如木质素和木屑)的浪费副产品上升,以创建可持续的3D打印材料与其粘合剂喷气技术兼容。

经济升级的木质素

使UD研究与该地区其他研究区分开来的是,它的重点是展望过程的经济学。升级木质素的主要缺点之一是,许多现有过程在非常高的温度下运行,因此昂贵且难以扩展。当前的工业技术还包括与传统溶剂,温度或压力相关的安全问题,资本成本和能源消耗。

为了应对这些挑战,UD研究团队取代了甲醇,甲醇是一种用于木质素解构的传统溶剂,甘油能够在正常的大气压力下进行该过程。甘油是一种廉价的成分,通常用于液体化妆品,肥皂和洗发水的保湿效果,但也可以用来将木质素分解成其化学块中,从中可以从中可以从中可以从中进行诸如3D打印树脂(例如3D印刷树脂)的广泛产品制成。

Replacing methanol with glycerin provided the same chemical functionality but at a much lower vapor pressure, eliminating the need for a closed system. This enabled the researchers to complete the process’ reaction and separation steps simultaneously, leading to a more cost-effective system.

根据研究人员的说法,在大气压力下运行不仅更安全,而且还提供了一条直接的途径,可以将方法从小批次延伸到连续运行,他们说这将创造出更便宜,更快且手动较少的材料。

Assessing economic viability

The method was developed over the course of a year to ensure its repeatability and consistency, and during this time the economic feasibility of the process was also assessed.

该团队研究了该团队可以使用新创建的SLS 3D打印材料来创建哪些类型的产品并估算其物理特性的数据集。这使团队能够对系统进行建模,以查看创建的材料是否在经济上可行。

这些模型从项目合作伙伴获得的各种制浆过程中评估了技术木质素废物CanmetENERGYin Canada. This enabled them to consider how upstream costs like the feedstock price or yield would impact the economics of the method further along the process.

根据模型,与常规的高压工艺相比,UD的低压方法可以降低从软木牛皮木质木质蛋白产生基于生物的压力敏感性粘合剂的成本。虽然科学家承认,对于研究中使用的其他类型的技术木质素,成本优势较不明显,但软木牛皮木质素是纸浆和造纸行业最常见的技术木质素类型之一。

The researchers’ analysis demonstrated that while yield plays a major role in plant economics, the cost to operate the new, low-pressure process was significantly lower than that of the conventional process “in all cases”, offering reduced capital costs and the generation of valuable co-products. The team also carried out a life-cycle assessment (LCA) to find out how much greenhouse gas emissions are generated by the process, the data of which can be used in the future to explore further ways to optimize the process.

With a patent currently pending for their ambient pressure process, the researchers believe the method offers “a lot of potential” for using renewable resources to make various types of plastics in favor of fossil fuels.

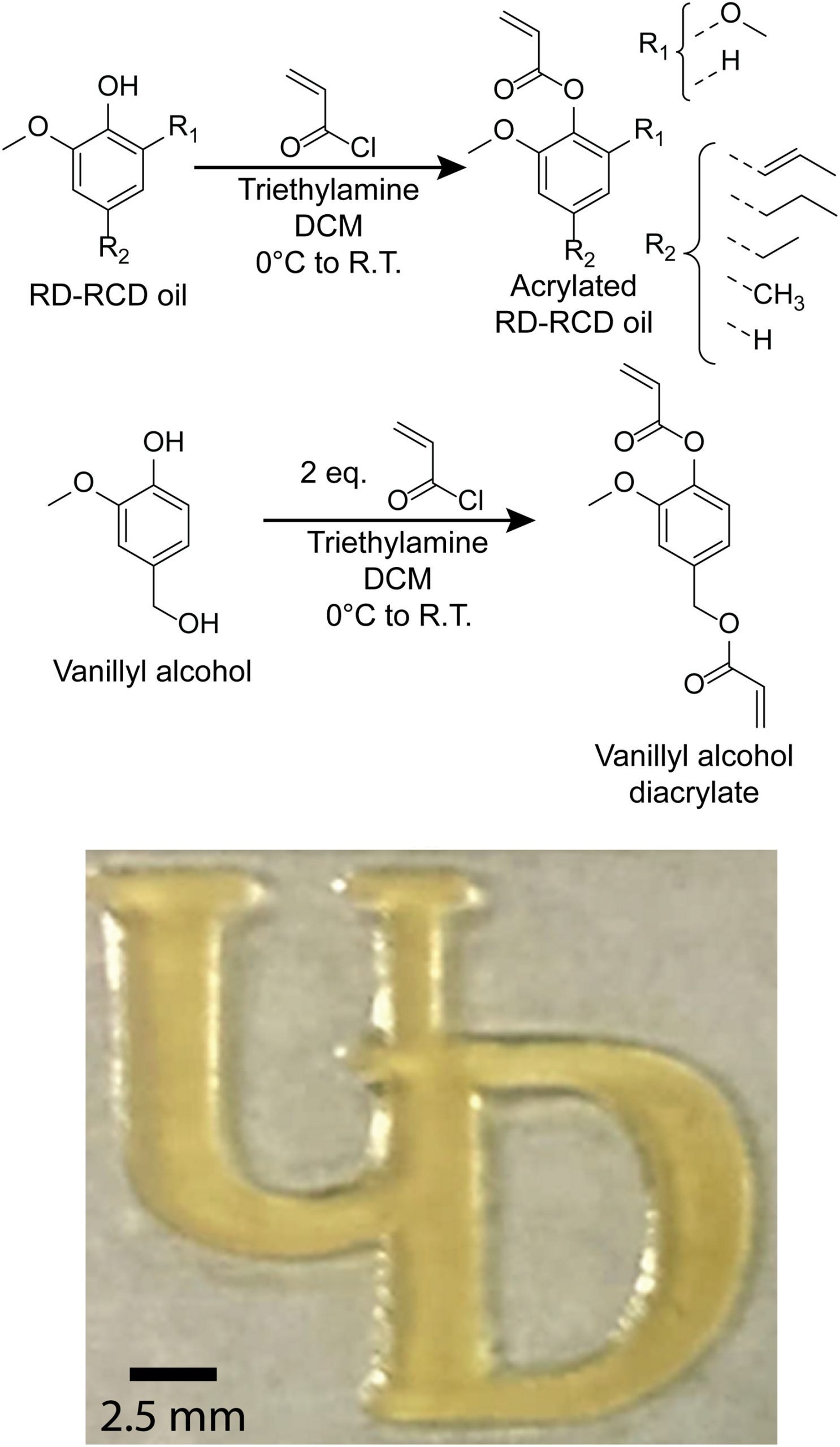

有关该研究的更多信息可以在标题为:“Ambient-pressure lignin valorization to high-performance polymers by intensified reductive catalytic deconstruction,”发表在《科学进步杂志》上。The paper was co-authored by R. O’Dea, P. Pranda, Y. Luo, A. Amitrano, E. Ebikade, E. Gottlieb, O. Ajao, M. Benali, D. Vlachos, M. Ierapetritou, T. Epps.

Subscribe to the3D打印行业通讯for the latest news in additive manufacturing. You can also stay connected by following us onTwitter并喜欢我们Facebook。

寻找添加剂制造业的职业?雷电竞充值访问3D打印作业for a selection of roles in the industry.

订阅我们YouTube频道for the latest 3D printing video shorts, reviews and webinar replays.

特色图片显示one of the end-products the UD researchers and colleagues are investigating is the creation of bio-resins for 3D printing. Photo via Paula Pranda.