研究人员德克萨斯农工大学已经提出了一种新型的基于3D打印的方法,可以准确模拟液压压裂或“压裂”油和天然气开采过程。

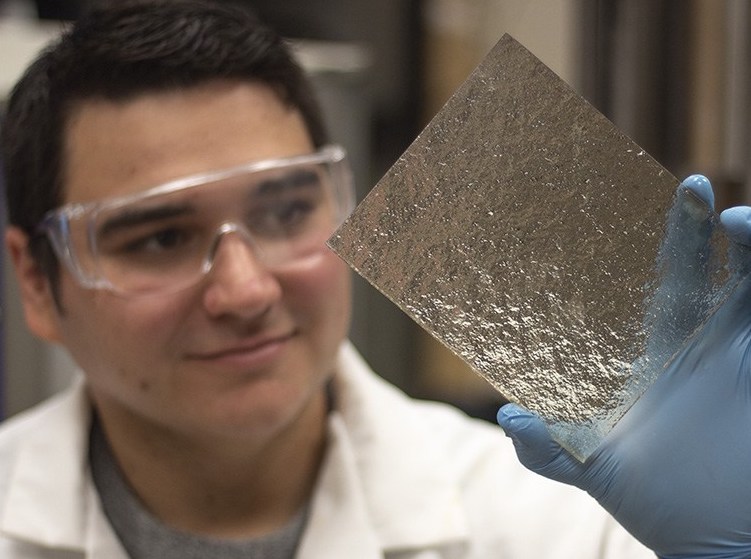

Working with local research universityColorado School of Mines,工程师加布里埃尔·塔特曼(Gabriel Tatman)设法开发了清晰的印刷模型,该模型揭示了压裂过程中使用的流量材料的影响,这种现象通常从视图中遮盖。

Made using rock fracture data recovered from actual oil drilling sites, it’s believed that these models could uncover previously-unseen hydraulic fracturing behaviors, and ultimately enable industry firms to optimize their oil and gas recovery efforts.

塔特曼解释说:“我们可以使用捕获特定形成特征的常见地统计方法来模拟断裂表面。”“通过3D打印,我们可以为实验应用创建这些模拟表面的物理版本。”

“We’re not the first to 3D print rock surfaces, but we are the first to do resin 3D printing for this particular application.”

压裂:一种有争议的采矿方法

Essentially, ‘fracking’ describes a mining process in which drilling is used to access vast shale oil and gas resources under the sea. To effectively extract these fuels from shale bedrock, water, aggregates and chemicals need to be forced into subsea formations at high pressures, which, according to critics, can cause lasting environmental damage.

Once this initial stage is complete, differently-sized grains of sand called ‘proppants’ are flushed down into the fractures created in a sort of slurry, to hold them open so that oil and gas can flow into a well. Additionally, so-called ‘diverters,’ made of dissolvable/recoverable chemical or mechanical materials, also tend to be used to strategically block proppants’ paths and help direct mined resources.

撇开压裂的生态影响,这种做法对于许多国家的油储备仍然至关重要,美国能源信息管理局(EIA) estimating that in 2020, 65% of the country’s crude oil came from shale. However, by its very nature, the mechanics of fracking take place deep underground, making it difficult to fully-understand and perfect.

A novel fracking modelling approach

To better understand rock formations, Tatman initially began toying with the idea of using 3D printing as an undergraduate, when he managed to create a casting containing a complex, acid-dissolved flow channel structure. Impressed by his work, Texas A&M Professor Ding Zhu encouraged her student to test the approach’s potential in further studies, eventually leading to his mining model discovery.

Since becoming a postgraduate, Tatman has managed to apply his rock-printing process to simulate fracking, by producing clear samples with a micrometer-level of fracture surface detail. When proppant and diverter are flushed through these models, it’s possible to directly observe their behaviors for the first time, an advance that his Texas A&M colleagues have called “groundbreaking” for shale mining.

Compared to existing proppant flow ‘conductivity’ research, which often relies on the use of standard lab equipment, the researcher’s approach is said to yield more realistic, rough fracture surface models, which can potentially be used to make molds capable of yielding repeatable cement test structures, and ultimately attaining more consistent fracking experiment results.

Acknowledging that the characteristics of fractures tend to vary in each shale formation, Tatman says that his approach will eventually be used to aid future research, by creating a proppant behavior database for different reservoirs.

In fact, the engineer also believes that 3D printing can be deployed in a similar way in other areas, such as gaining an understanding of plugging agent behaviors, in the wormhole geometries formed within acid-treated reservoirs, however, while Tatman is proud of his contribution to the project, he is now set to leave for a full-time industry position.

塔特曼总结说:“过去五年,在3D印刷界看到的发展水平非常出色。”“自高中以来,3D打印一直是我一直对此充满热情的事情。我能够将我的生活中的爱好方带到研究方面并将两者融入生产力的事物一直是我真正感到自豪的事情。”

3D printing’s oil and gas potential

Due to the remote nature of offshore mining operations, oil and gas firms are increasingly turning to 3D printing to in-source their spare part production, and ensure their drilling plans go interrupted.Protolabs,例如,发布了它的决策时间报告last year, in which it found that up to 83% of industry firms could now adopt 3D printing in this way.

能源服务提供商狩猎Plc还通过收购3D印刷局的27%来认识到该技术在石油和天然气领域的潜力Cumberland Additive。在这一过程中,冷杉m has made its first move into the additive manufacturing sector, and it’s said to see its acquired technologies as being compatible with the needs of its offshore clientele.

Over in Brazil,卡尔·蔡司,,,,SENAIandPetróleoBrasileiro(Petrobras) are also working to advance the application of metal 3D printing within the country’s oil and gas industry. Over the next 18 months or so, the companies aim to validatenovel DED and PBF methodologiesfor producing critical industry components, focusing in particular on the role of powder aging and degradation on defect formation.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D打印行业通讯or follow us on推特or liking our page onFacebook。

为了深入研究添加剂制造,您现在可以订阅我们的雷电竞充值Youtubechannel, featuring discussion, debriefs, and shots of 3D printing in-action.

您是否正在寻找添加剂制造业的工作?雷电竞充值访问3D打印作业在行业中选择一系列角色。

Featured image shows petroleum engineering graduate student Gabriel Tatman holding one of his 3D printed models. Image via Texas A&M University.