Israeli 3D printer manufacturerXJethas delivered its first commercial metal 3D printing system to additive manufacturing service provider金丹.

Originally released back in 2019, theCarmel 1400M 3D printer据报道,first material jetting system in the world capable of processing both metals and ceramics, combining repeatability and part quality for industrial applications.

基于XJET专有纳米颗粒喷射(NPJ)工艺,该机器具有大型500 x 280 x 200mm构建托盘,并可以打印出具有高吞吐量的金属零件。

“我们在金属制造方面拥有丰富的丰富经验,包括添加剂和减法过程。XJET的金属系统提供了市场需求量很高的功能,但其他技术无法实现。” Azoth首席执行官Scott Burk说。“具有良好功能,高分辨率,良好表面饰面的零件在打印机上 - 在我们以前从未见过的水平上。与不涉及处理粉末的XJET系统合作的易用性和安全性是我们的另一个重要因素。”

XJet’s NanoParticle Jetting technology

All of XJet’s 3D printers operate on the company’s NanoParticle Jetting technology. The unique material jetting approach involves spraying nanoparticles embedded in a liquid shell. Once deposited onto a build plate, the liquid outer shells evaporate to leave behind solid, bonded parts made of fused nanoparticles. The resulting components feature high levels of detail, a great surface finish, and dimensional precision.

The firm launched its first NPJ systems, the卡梅尔1400和较小的卡梅尔700 3D打印机雷电竞app下载,在2017年。然后在2019年,XJet rebranded the Carmel 1400to distinguish which models could process ceramics (C) and which could process metals (M).

XJet has since delivered several of its ceramic 3D printers to clients, including aCarmel 1400C to Katholieke Universiteit Leuven(KU Leuven) in Belgium. This was the first XJet system to be implemented at an academic institution within Europe. The company also partnered with dentistry firmStraumannto advance the capabilities of theCarmel 1400C for dentistry applications.

最近,XJET还启动了Support Material Automatic Removal Technology, or ‘SMART’, post-processing station. Marketed as the “last link in the chain” for automated end-to-end 3D printing, the SMART unit uses intelligent algorithms to automatically remove supports from XJet-manufactured ceramic parts.

Hanan Gothait, CEO of XJet, adds, “We have developed the only metal AM technology available today based on the concept of direct material jetting. After amazing success with the XJet ceramic systems, we are now ready for the bigger dream, bringing to the market our metal solution.”

Commercializing the Carmel 1400M

With Azoth as its latest customer, XJet has now officially commercialized the Carmel 1400M 3D printer. Operating underEast West Industrial Engineering (EWIE), Azoth’s background is in high-volume metal manufacturing for major firms such asFord,Chrysler, and劳斯莱斯. The firm was established when EWIE decided to finally enter the additive manufacturing sector in 2020.

金丹’s senior leadership came across XJet when it was searching the market for technologies capable of producing small, complex, and high-definition parts that conventional powder bed fusion simply couldn’t manage. Since NPJ prints with very small particles, it allows for tiny layer heights and extremely fine feature details.

Cody Cochran, Azoth’s co-founder and General Manager, explains, “My eureka moment came when we got some test parts through from XJet and I asked the team how they looked, and they responded that they were the best they’d ever seen. What we really liked were the small holes, very sharp corners, and very refined surface finish without needing any post-processing.”

除部分质量外,Azoth还希望从运营优势中受益。Carmel 1400m适用于原型制作和最终用途的生产,因此该公司将能够尝试各种设计迭代,并使用同一台机器将组件进行生产。

订阅3D Printing Industry newsletterfor the latest news in additive manufacturing. You can also stay connected by following us onTwitter, liking us onFacebook, and tuning into the3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit3D Printing Jobsfor a selection of roles in the industry.

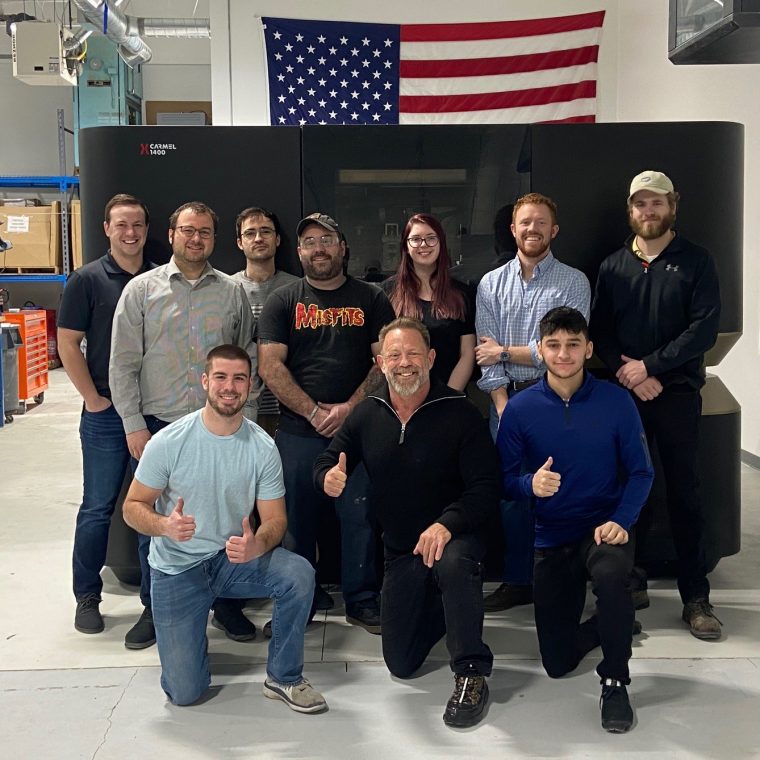

Featured image shows the Azoth team with their new XJet Carmel 1400M 3D printer. Photo via XJet.