3D printer OEM3D Systemshas partnered with Australian satellite developerFleet Space到3D打印射频(RF)贴片天线,用于在后者的Alpha卫星上使用。

具体而言,3D Systems的应用创新集团(AIG)帮助车队空间在短短三周内使用其设计并过渡到小批量生产DMP Flex 350metal printer. Fleet Space is in the process of procuring a DMP Flex 350 for its HQ in Beverley, Adelaide, to eventually bring patch antenna manufacturing in-house.

The 3D printed antennas will be a critical component of each of the satellites in Fleet Space’s Alpha constellation, which is slated for launch into low earth orbit (LEO) in 2023.

3D Systems Aerospace&Defense Segment的副总裁Michael Shepard博士说:“ 3D系统可以帮助航空航天客户加速创雷电竞充值新并降低风险。”“我们通过与客户合作为其需求提供正确的硬件,材料,软件和服务提供应用程序解决方案来做到这一点。在这种情况下,我们能够帮助车队太空技术在很短的时间内为其内部内部的卫星硬件带来合格的生产过程。”

舰队空间的崛起

Fleet Space is dedicated to becoming a leader in Australia’s budding space industry, which the country’s government expects will reach $12 billion by 2030, creating an additional 20,000 jobs. The company first appeared on the radar in 2018 when it launched Australia’s first set of commercial nanosatellites into LEO: the Proxima 1, Proxima 2, Centauri 1, and Centauri 2.

去年年底,舰队空间揭示了计划发射其Alpha卫星的计划,这被认为是世界上第一个完全3D印刷卫星。Once operational, the Alpha constellation will work in conjunction with theexisting Centauri constellationto provide continuous coverage at data rates of up to 520kbps.

更重要的是,双卫星系统将构成该公司Exosphere计划的骨干,该计划旨在通过微创的环境噪声断层扫描技术改造矿物勘探。从本质上讲,预计卫星能够在地球表面上查明关键资源的速度比传统方法(例如炸药,颤音机器和钻孔)快100倍。

每个版本的五十五个贴片天线

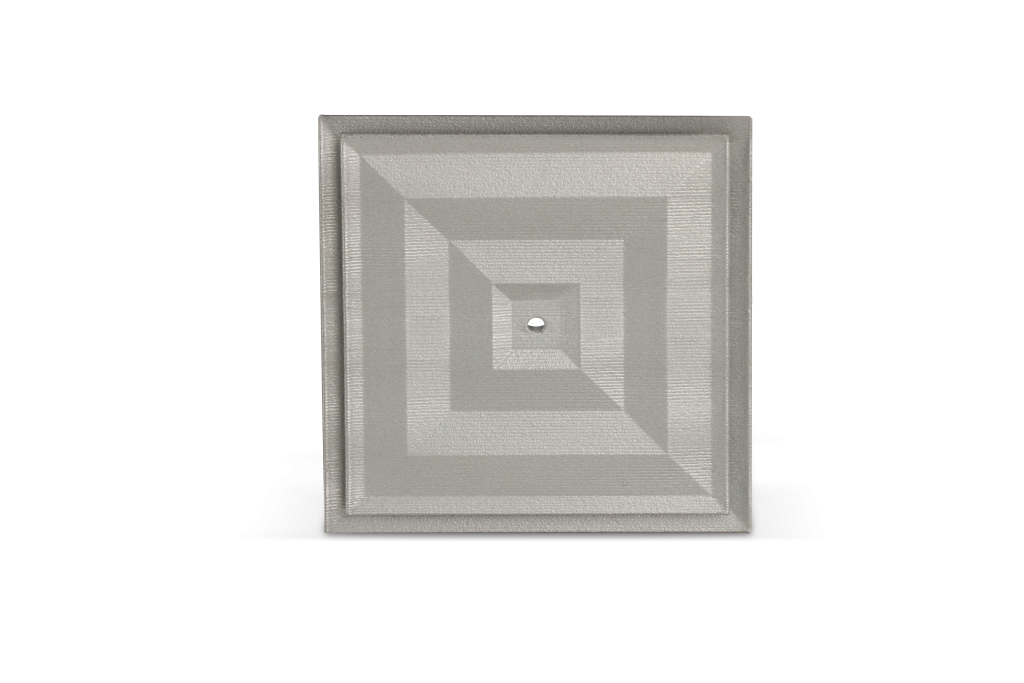

每个Alpha卫星最多将配备64个金属3D印刷贴片天线。车队太空团队最初设计了天线,以满足严格的尺寸,重量和性能要求,同时最大程度地减少了对后处理的需求。这样的几何形状只能使用增材制造技术制造。雷电竞充值

3D Systems’ AIG helped the company develop print processes for two different metals on the DMP Flex 350, LaserForm AlSi10Mg and Al6061-RAM2.

在这里,麻吉的真空室结构ne was crucial to the success of the builds, as it can maintain a low oxygen environment of <25 ppm. It not only heavily reduces argon gas consumption, but also enables an excellent surface finish with fine feature details. This is reportedly key to minimizing signal losses with antennas.

With the help of 3D Systems’ 3DXpert software, the partners are now able to 3D print batches of 55 RF patch antennas per print run on the DMP Flex 350.

Flavia Tata Nardini, founder and CEO of Fleet Space Technologies, said, “Together with 3D Systems’ AIG, we are unlocking the remarkable potential of additive manufacturing at our world-class facility in Adelaide, South Australia. This technology will enable our people to create the production processes that will deliver on Fleet’s ambition to launch more than 140 low earth orbit satellites in the Alpha constellation.”

Fleet Space isn’t the only company exploring 3D printed satellite components. Earlier this year, 3D Systems also announced that aerospace manufacturerAirbus签给了3D print critical parts for its upcoming OneSat satellite。与用于定义任务的传统卫星不同,空中客车公司表示,对于可调覆盖面积,容量和频率,Onesat将完全重新配置。

Elsewhere, multinational electronics manufacturerMitsubishi Electric最近开发了一种新的方法3D printing freeform satellite antennas in-orbit。围绕一个新开发的技术liquid resin, which is not only custom-made for manufacturing in a vacuum, but is capable of photopolymerization via the sun’s UV rays.

Subscribe to the3D打印行业通讯有关增材制造中的最新消息。雷电竞充值您也可以通过关注我们来保持联系Twitter,喜欢我们Facebook, and tuning into the3D Printing Industry YouTube Channel。

寻找添加剂制造业的职业?雷电竞充值访问3D Printing Jobsfor a selection of roles in the industry.

特色图像显示了DMP Flex 350上打印的RF贴片天线3D。通过3D系统照片。