3D printed buildings on Mars are a stage closer withNASA’s announcement of the latest results in its3D Printed Habitat Centennial Challenge。

In conjunction with the布拉德利·佩罗里亚大学, Illinois, the Habitat Challenge invites proposals for 3D printed off-world structures that can be made with the kind of materials available on Mars.

Monsi Roman,program manager for NASA’s Centennial Challenges,said,“They are not just designing structures, they are designing habitats that will allow our space explorers to live and work on other planets. We are excited to see their designs come to life as the competition moves forward.”

将材料运送到火星

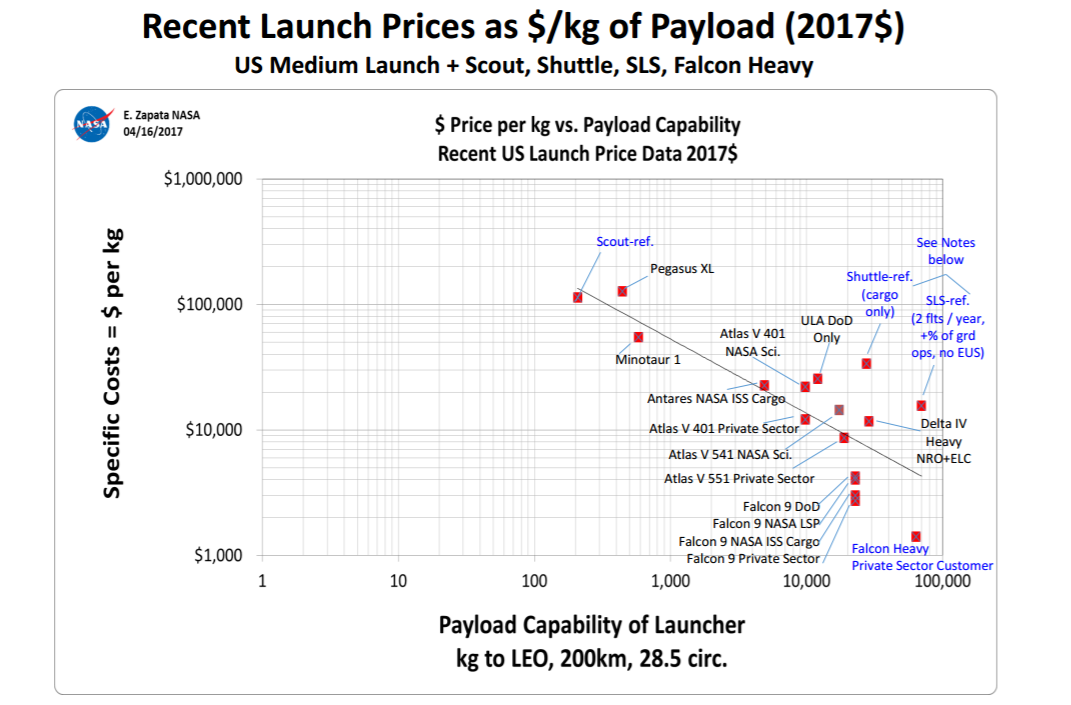

Considering the limitations and costs of transporting materials to Mars, using in situ resources is an area ofconsiderable研究活动。例如,NASA datashows that using the Antares NASA ISS Cargo it costs over $10,000 to put a kilo of payload into a Low Earth Orbit (LEO), and Pegasus XL costs over $100,000.

By using火星雷果地, the loose bedrock of the red planet, or other space-sourceable materials, like ice, NASA hopes to be able to dramatically cut down this price.

NASA栖息地挑战的阶段

NASA Habitat Challenge is divided into three phases, with 18 teams taking part.

在挑战的第一阶段,设计竞赛(2015年)中,团队创建并介绍了计划结构的建筑细节。

For Phase 2, the Structural Member Competition, completed in 2017, NASA partnered with the Bradley University of Peroria, Illinois. This phase required that the teams build elements of the structures either from a combination of indigenous materials and recyclables, or indigenous materials alone. Phase 2 had a prize purse of $1.1 million and served as a qualifier for the next phase.

这competition is now in its final phase: the On-Site Habitat Competition. There are three construction levels and two virtual levels. At the virtual levels, teams must use Building Information Modelling (BIM) software to design the habitats. Finally, at the construction levels, the teams must be prepared to autonomously 3D print the elements of the habitat.

Phase 3 winners of NASA’s 3D Printed Habitat Centennial Challenge

这$100,000 prize purse of Virtual Modeling Stage (Phase 3) was distributed among the top five teams.

- 来自阿肯色州罗杰斯的Zopherus团队是一等奖20,957.95美元的冠军。

-AI。全球的建筑实践,skunkworks SpaceFactory, New York, won the second prize, $20,957.24.

-Kahn-Yates, Mississippi, a team of design and architecture firm, theKahn Companies,占领第三名,被授予20,622.74美元。

- 第四名($ 19,580.97)被占领SEArch+/Apis Corof New York, known for3D printing a building in 24 hours。

-At the fifth place was the Northwestern University of Evanston, Illinois winning $17,881.10.

火星栖息地

Zopherus团队设计了一个受蜘蛛启发的步行地着陆机器人。着陆器到达特定位置,并使用3D打印来建立自己的自身,从而采购了当地的原材料,包括由火星冰,氧化钙和火星骨料制成的混凝土。

A funky multi-storied 3D printed house, that looks like a set-piece from a 60s space movie, was SEArch+/Apis Cor’s contribution to the project.

这construction has 9 steps. It begins with the deployment of payload. In the fifth step the foundations of the structure are 3D printed, in the eighth step the autonomous robot 3D prints regolith shell, and in the ninth step plants are grown and the structure is ready for the arrival of the crew.

材料的采矿空间

Other space organizations and companies are also looking towards 3D printing technology to provide solutions in space.

这European Space Agency(ESA)总部位于法国巴黎,与fotec,一个研发部门应用科学大学,奥地利和3D从包含“Mars dust”.

月球和火星的采矿资源是空间行业的下一个野心。这Moon Express(California), a company taking part inGoogle Lunar XPRIZE希望超越赢得奖品,并找到为其资源开采月球的方法。

For more news on the mission to Mars, subscribe to our通讯, or follow us onFacebookand推特。对于3D打印行业的工作,请访问我们job site。

Featured image shows the virtual design of AI. SpaceFactory’s Mars habitat named “MASHA”. Photo via NASA