雷电竞充值增材制造数据专家森沃尔has showcased how its machine learning (ML) technology can be used to accelerate the qualification of new aerospace 3D printing materials.

根据美国3D打印加速器授予的合同工作美国制造,该公司部署了森沃尔MLsoftware to rapidly and cost-effectively identify property allowables during material R&D. Funded by the美国空军(USAF),人们认为该项目的发现可能是生产新一代耐用轻量级零件以及具有航空航天和商业应用的关键。

“我参与了几种添加剂制造过程和飞行材料的资格,”退休的首席科学家威廉·E·弗雷泽(William E. Fraz雷电竞充值ier)博士说NAVAIRand project participant, “and in my opinion, the further development of this technology will have a positive impact on the cost, schedule, and performance of both Department of Defense (DoD) and commercial platforms.”

“Senvol’s ML-enabled approach directly addresses a major industry challenge: the rapid and cost-effective development of additive manufacturing material property allowables.”

森沃尔ML’s military potential

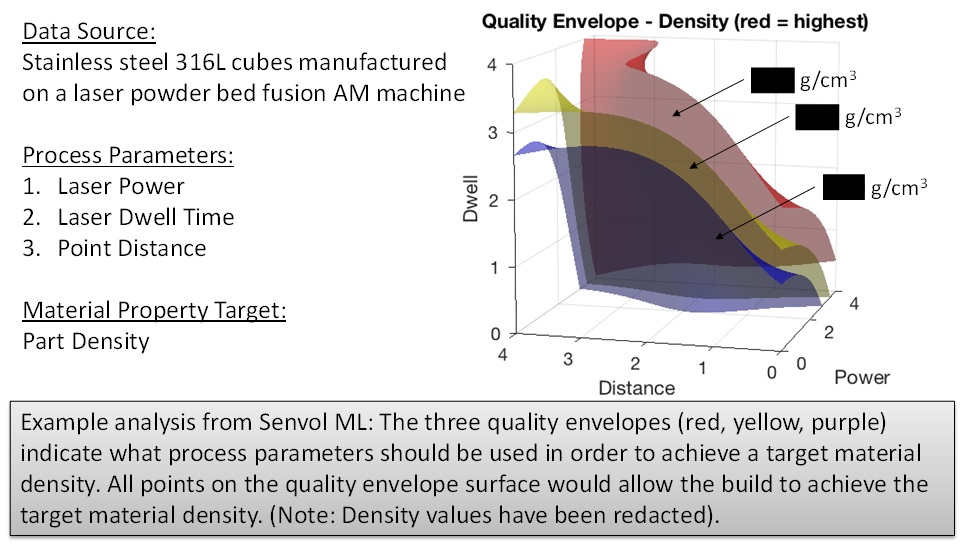

实际上,Senvol ML是一个数据驱动的软件,可用于分析3D打印参数与材料的最终性能之间的关系。与所有已知AM流程兼容的程序没有绑定到任何一种技术,使用户能够根据预设的目标机械性能为其系统或材料生成一组参数。

Senvol ML在很大程度上归功于其模块化的集成计算材料工程或“ ICME”框架。分为四个模块,该ICME量化了收集在参数,材料属性,过程签名和机械性能的数据之间的关系,以生成对任何结果零件如何以结的速度行为的预测。

为此,Senvol ML为航空航天,国防,消费者,医疗,汽车和石油和天然气部门的采用者提供了重要的质量保证工具,现在该技术也越来越多地发现军事申请。仅自2020年以来,Senvol就使用其软件来帮助印刷大型航空零件and develop amissile qualification workflow, whilegaining DoD fundingfor further R&D.

“Senvol’s data-driven machine learning technology has the potential to substantially reduce the cost of material allowables development,” says Senvol President Zach Simkin. “By demonstrating an entirely new – and significantly more efficient – approach to allowables development, Senvol aims to drive tremendous value for the US Air Force, the America Makes membership, and the additive manufacturing industry at large.”

Material qualification at pace

森沃尔’s America Makes research project was centered around the process of identifying a material’s ‘property allowables.’ Also known as ‘design allowables,’ these values essentially represent a statistically-determined minimum durability property that materials need to have, in order to make them viable within particularly demanding applications.

Specifically, the program tasked the firm with showcasing how the machine learning algorithms of its Senvol ML software can be used as a means of accelerating this process, while driving down the vast amount of empirical data normally required to do so, something that can be a roadblock to 3D printing’s wider military deployment.

“Additive manufacturing is a modern and digital manufacturing method with rapidly tailorable processing,” explains Dr. Brandon Ribic, Technology Director of America Makes. “To continue to use traditional material allowables development approaches, is a bottleneck to wider material and process options and capabilities for additive manufacturing.”

根据Ribic Senvol设法克服这个s bottleneck by developing a data analysis-driven approach to qualification, which exhibited the capabilities of its software in a “very powerful” way. In fact, working withNorthrop Grumman, 这国家航空研究所(niar),Stratasys Direct Manufacturingand朝圣咨询据说,该公司能够识别实质性材料,同时优化其数据生成要求。

尽管该计划使Senvol的精力集中在寻找通过粉末床融合机处理的阻燃尼龙11的属性允许物,但它说其方法可以应用于“任何AM过程,机器和材料”,以使其参数限定比传统方法更快,负担得起,准确。

“The results of this America Makes program were incredibly successful,” concluded Simkin. “Additionally, we identified several other opportunity areas to go deeper into the machine learning capabilities to address this critical need for the industry. We look forward to continuing to partner with industry to advance this cutting edge area.”

A fresh approach to qualification?

Compared to conventional ‘trial and error’ approaches to material qualification, machine learning-based algorithms offer a means of eliminating the human mistakes behind failed prints. Though many such programs remain at an experimental level, the benefits of software developed by the likes of Senvol ML andintellegens, are now beginning to make it onto the factory floor.

Just last year, the latter worked with the谢菲尔德大学的AMRCandBoeing,提出一个newly-optimized approach to 3D printingaerospace parts. Utilizing the firm’s own炼金板ML平台, 这project was set up with the goal of enhancing the powder bed fusion process, in a way that ensured components could be produced faster, cheaper and from more materials than before.

Similarly, engineers at theMassachusetts Institute of Technology(MIT) have developed an开源ML算法that’s designed to help a wider audience expedite the process of identifying 3D printable materials. Packaged within their ‘自动’ software, the team’s program is capable of automatically identifying viable materials with desired qualities such as toughness, rigidity and strength.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the3D打印行业通讯or follow us on推特or liking our page onFacebook。

For a deeper-dive into additive manufacturing, you can now subscribe to ourYoutube频道,包括3D打印进程的讨论,脱毛和镜头。

您是否正在寻找添加剂制造业的工作?雷电竞充值访问3D打印作业for a selection of roles in the industry。

Featured image shows a fleet of US Air Force aircraft. Photo via Mikayla Heineck, US Air Force.